أدوات قياس المستوى

الصفحة الرئيسية » المنتجات » أدوات قياس المستوى » مستشعر المستوى بالموجات فوق الصوتية

مستشعر المستوى بالموجات فوق الصوتية

The ultrasonic level gauge is a non-contact, high-reliability, and cost-effective device for accurate ultrasonic level measurement of liquids, slurries, and solids in industrial environments. Designed for easy installation and low maintenance, it offers a reliable solution for water treatment, municipal, chemical, metallurgical, and machinery manufacturing applications.

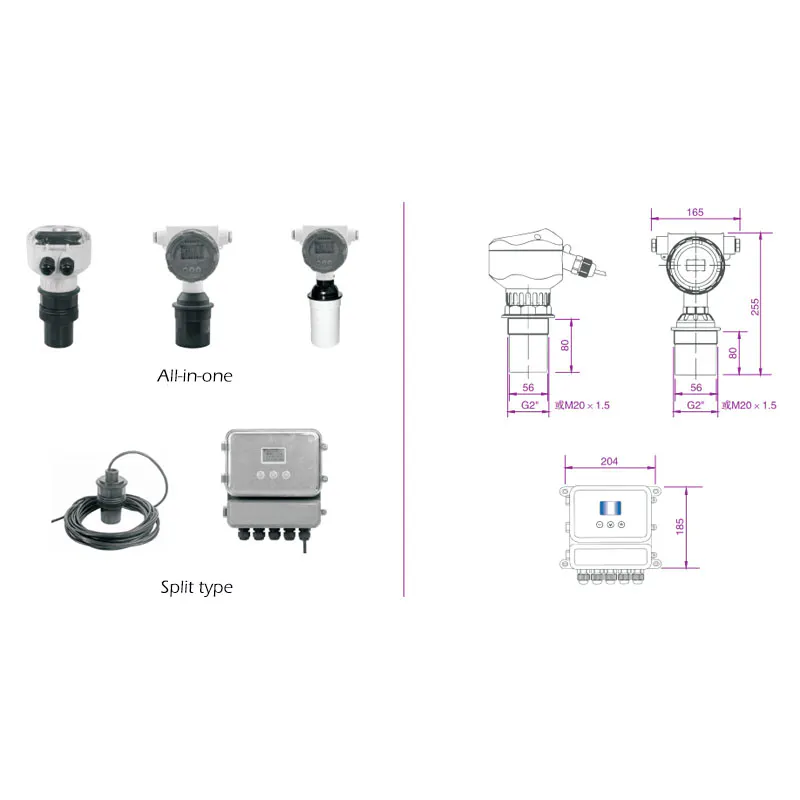

Ultrasonic level sensors are available in two types: integrated and separated. The integrated type combines the sensor and host into a single unit, providing simple and convenient installation. The separated type allows the sensor and host to be installed independently, making it ideal for storage tanks, silos, and bracket-mounted setups.

وصف أدوات قياس المستوى

Ultrasonic Level Sensor-Features

Non-contact measurement: Accurate monitoring unaffected by medium viscosity, density, or other properties, with strong anti-interference performance.

Environmentally friendly materials: Safe for the medium and prevents contamination.

Food and pharmaceutical safe: Non-toxic design suitable for sensitive applications.

Level alarm capability: Optional relay output allows real-time level alarm functionality.

User-friendly configuration: Panel button interface enables fast and convenient parameter setup.

Advanced signal processing: Microprocessor-based echo processing ensures reliable measurement in complex conditions.

Self-learning and compensation: Automatic echo identification and temperature compensation minimize drift and improve accuracy.

Rugged design: IP67 protection allows operation in most outdoor and harsh industrial environments.

Level Ultrasonic Sensor-Common Applications

Water Tanks: Ultrasonic water level sensors provide accurate, real-time monitoring for residential, commercial, and industrial tanks, preventing overflow or shortages.

Industrial Processes: Used in chemical, food & beverage, pharmaceutical, and wastewater treatment industries to maintain precise ultrasonic level measurement in tanks and vessels.

Pump Control: Can integrate with pump systems for automatic water level management in irrigation, sewage, and drainage systems.

Environmental Monitoring: Ideal for rivers, lakes, and reservoirs, enabling ultrasonic water level detection for flood forecasting and water resource management.

Hydroelectric Power Plants: Monitors reservoir levels to regulate turbine flow, ensuring safe and efficient power generation.

Aquaculture: Maintains optimal water levels in ponds, tanks, and raceways, supporting healthy growth of aquatic species.

Swimming Pools and Spas: Ensures water levels remain within safe and comfortable ranges to prevent overfilling or draining.

Ultrasonic Water Level Sensor-Working Principle

إن ultrasonic level sensor measures liquid levels using non-contact ultrasonic technology. It works in four main steps:

Ultrasonic Emission: The sensor emits ultrasonic pulses, typically in the frequency range of 20 kHz to 200 kHz.

Propagation: The pulses travel through air or other media until they encounter the liquid surface. Part of the energy reflects back while the remainder continues downward.

Reflection and Reception: The sensor’s receiver captures the reflected ultrasonic waves. The time delay between emission and reception corresponds to the travel time of the pulses.

Level Calculation: By calculating the propagation time, the sensor determines the distance from the liquid surface to the sensor, which directly indicates the liquid level.

This non-contact ultrasonic measurement ensures accurate and reliable monitoring in tanks, reservoirs, silos, and other industrial applications, making it ideal for ultrasonic water level detection and ultrasonic level measurement.

Ultrasonic Tank Level Sensor-Structure

إن ultrasonic level sensor is available in two types: integrated (one-piece) type and separated (two-piece) type, designed for flexible installation and diverse industrial applications.

Integrated Type:

The sensor and host are combined into a single unit.

Simplifies installation and wiring.

Ideal for compact tanks or vessels where space is limited.

Separated Type:

The sensor probe is installed separately from the host unit.

Suitable for large storage tanks, silos, or bracket-mounted installations.

Allows easier maintenance and flexible positioning for optimal signal reception.

Key Components:

Sensor Probe: Stainless steel or PVDF, corrosion-resistant.

Electronics Housing: IP67 protection, dustproof and waterproof.

Display/Control Module: Optional LCD/LED interface for local readings.

Connection Interface: Standard cable or M12 connector for signal transmission.

This design ensures accurate ultrasonic level measurement and reliable performance in diverse industrial environments.

معلمة أدوات قياس المستوى

| Measuring Medium | liquid or material that is generally or corroded |

| نطاق القياس | 5m, 10m, 15m, 30m, 50m, 60m |

| Probe Material | PTFE |

| الدقة | ± 3 مم (لا يوجد سطح ماء هادئ الموجات) |

| القرار | 3~5mm or 0.1% (take large value> |

| وضع العرض | شاشة LCD، يمكن ضبط المعلمات من خلال أزرار اللوحة |

| إخراج الإشارة | 4 ~ 20mADC |

| مقاومة الحمل | 250Ω (when two-wire 24V power supply);500Ω (when four-wire 220VAC power supply) |

| مخرج الترحيل | 2 مجموعات اختيارية، وحالة الترحيل قابلة للبرمجة |

| Relay Contact Capacity | 250VAC 8A. 30VDC 5A |

| درجة حرارة العمل | -25~80 °C |

| Rated Pressure | -0.1 ~ 1.0MPa |

| واجهة الاتصال | RS232، RS485/مودبوس RS232 |

| مزود الطاقة | Standard 24 V DC; Optional 220VAC; Battery type 3.8V 25600mAh |

| الواجهة الكهربائية | M20*1.5, 1/2″NPT |

| درجة مقاومة للانفجار | Exia II C T6 Ga/Exd IIC T6 Gb |

| Protection level | IP67 |

Non contact liquid level indicator, LCD display, with rs485 signal output

أدوات قياس المستوى تصنيع المعدات الأصلية/التصنيع حسب الطلب

Ultrasonic Level Measurement-OEM ODM

We offer full OEM/ODM services for ultrasonic level sensors, providing flexible solutions tailored to your industrial needs. Our customization options include:

Measurement Range & Accuracy: Adjust the detection range and precision to match your specific application.

Output Signals: 4–20 mA, HART, or Modbus interfaces for seamless integration.

Material & Housing: Stainless steel, PVDF, and IP67-rated protection for harsh environments.

Installation Options: Integrated (one-piece) or separated (two-piece) types, with flange, bracket, or threaded mounting.

Display & Control Modules: Optional LCD/LED indicators for local monitoring.

Our experienced factory ensures high-quality production, fast prototyping, and reliable delivery, enabling you to implement customized ultrasonic level measurement solutions efficiently.

An ultrasonic level sensor is a non-contact device that measures the distance to the surface of liquids or solids using high-frequency sound waves. The sensor emits ultrasonic pulses, which reflect off the material surface; the time-of-flight determines the level.

Manufacturer advantages:

No physical contact, reducing corrosion and contamination

Suitable for open tanks, silos, and reservoirs

يوفر continuous, real-time level monitoring

Ultrasonic level sensors are ideal for non-corrosive, moderate-temperature applications:

Oil & Gas: Monitoring storage tanks for fuel, diesel, and light crude oil

Chemical: Measuring water-based or non-corrosive chemicals

Pharmaceutical: Tank and hopper level measurement for hygienic solutions

Manufacturer perspective: Proper sensor selection ensures accurate measurement without risking chemical contamination or sensor degradation.

| eature | مستشعر المستوى بالموجات فوق الصوتية | Radar Level Gauge | Magnetic Level Gauge |

|---|---|---|---|

| الدقة | ±5–10 mm | ±1–3 mm | ±1–5 mm |

| اتصل بنا | Non-contact | Non-contact | Float inside chamber |

| Pressure tolerance | Low | High | High |

| Temperature tolerance | Moderate | High | High |

| Maintenance | متوسط | Low | Very low |

Manufacturer note: Ultrasonic sensors are best for open-air or low-pressure tanks, while radar and magnetic gauges are preferred for high-pressure, high-temperature, or corrosive fluids.

Yes. Ultrasonic sensors are commonly used in:

Water & Wastewater: Reservoirs, clarifiers, and sludge tanks

HVAC Systems: Chilled water and hot water storage tanks

Environmental Monitoring: Rainwater and stormwater level measurement

Manufacturer tip: Ensure proper tank geometry and echo-free mounting for accurate measurement.

Energy & Power: Cooling water tanks, fuel level monitoring

Automotive: Fluid level measurement in manufacturing tanks

Marine & Shipping: Ballast water, fresh water, and bilge monitoring

Mining & Environmental: Tailings, slurry, and sediment measurement

Manufacturer insight: Ultrasonic sensors provide cost-effective, non-contact measurement for applications with moderate process conditions.

Medium characteristics: Density, foam, vapor, turbulence

Tank geometry: Shape, size, and internal obstructions

Temperature & pressure: Typically <80°C and <1 MPa for standard models

Output: 4–20 mA, HART, Modbus

Installation: Avoid obstructions in the beam path; consider mounting height

Proper selection ensures stable, reliable, and maintenance-efficient level measurement.

لماذا تختار إنسترافا

باختيارك Instrava، ستحصل على شريك يتمتع بفهم عميق للتطبيقات الصناعية والخبرة اللازمة لمواجهة التحديات التشغيلية الحالية.

يمتد دورنا إلى ما هو أبعد من المنتجات - فنحن ندعم نجاحك من خلال حلول يمكن الاعتماد عليها والتزام طويل الأجل.

الابتكار المدفوع بالهندسة

يسترشد الابتكار في Instrava بالمتطلبات الصناعية الحقيقية. نحن نعمل باستمرار على تحسين تقنياتنا لمعالجة التحديات التشغيلية المتطورة، مما يضمن أداءً عمليًا وموثوقًا في البيئات الصعبة.

التخصيص الخاص بالتطبيق الخاص بالتطبيق

نحن نقدم التخصيص على المستوى الهندسي لمطابقة ظروف عملية محددة. بدءًا من نطاق القياس والمواد إلى إشارات الخرج وخيارات التثبيت، يتم تكوين حلولنا لتناسب التطبيقات الحقيقية.

جودة وموثوقية مثبتة

الجودة والموثوقية أمران أساسيان لكل منتج من منتجات إنسترافا. تُصنع أدواتنا تحت رقابة صارمة على الجودة ويتم اختبارها بدقة، وتوفر أداءً دقيقًا ومستقرًا وطويل الأجل.

القدرة العالمية مع الدعم المحلي

تجمع إنسترافا بين الخبرة الهندسية العالمية والدعم المحلي سريع الاستجابة، مما يضمن لشركائنا الاستفادة من التكنولوجيا المتوافقة دوليًا والخدمة الإقليمية في الوقت المناسب.

محفظة المنتجات الشاملة

تتيح لنا محفظتنا الواسعة من أدوات القياس والتحكم تلبية مجموعة واسعة من الاحتياجات الصناعية، مما يوفر حلولاً متكاملة من مصدر واحد وموثوق.

الدعم الهندسي الموجه للشركاء

نحن نعمل عن كثب مع شركائنا بدءاً من الاستشارات الفنية وحتى دعم ما بعد البيع. ينصب تركيزنا على تقديم حلول تخلق قيمة دائمة وتدعم النجاح التشغيلي على المدى الطويل.