Instrumentos de medición de nivel

Inicio » Productos » Instrumentos de medición de nivel » Medidores de nivel por radar

Medidores de nivel por radar

Radar level gauge is a high-precision instrument for continuous level measurement of liquids, slurries, and chemicals in tanks and vessels. Designed for various industries, including chemical, oil & gas, water treatment, and power generation, it provides reliable, contactless measurement even under harsh conditions. With robust construction and explosion-proof options, it ensures long-term stability and accurate readings. Custom radar fuel level gauge and radar liquid level sensor options are available to meet specific application requirements.

Instrumentos de medición de nivel Descripción

Radar Gauge For Level Measurement-Features

Compact antenna design for easy installation and maintenance; non-contact measurement ensures no wear or contamination.

Resistant to corrosion, bubbles, dust, and vapor; performance is stable under temperature and pressure changes.

High-frequency radar with short wavelength provides accurate reflection even from inclined or low-dielectric surfaces.

Narrow beam angle concentrates energy, enhancing echo detection and minimizing interference.

High signal-to-noise ratio ensures precise measurement and reliable performance for fluctuating liquid or solid levels.

Suitable for measuring both liquids and solids, including low-dielectric materials, over a wide range of tank sizes.

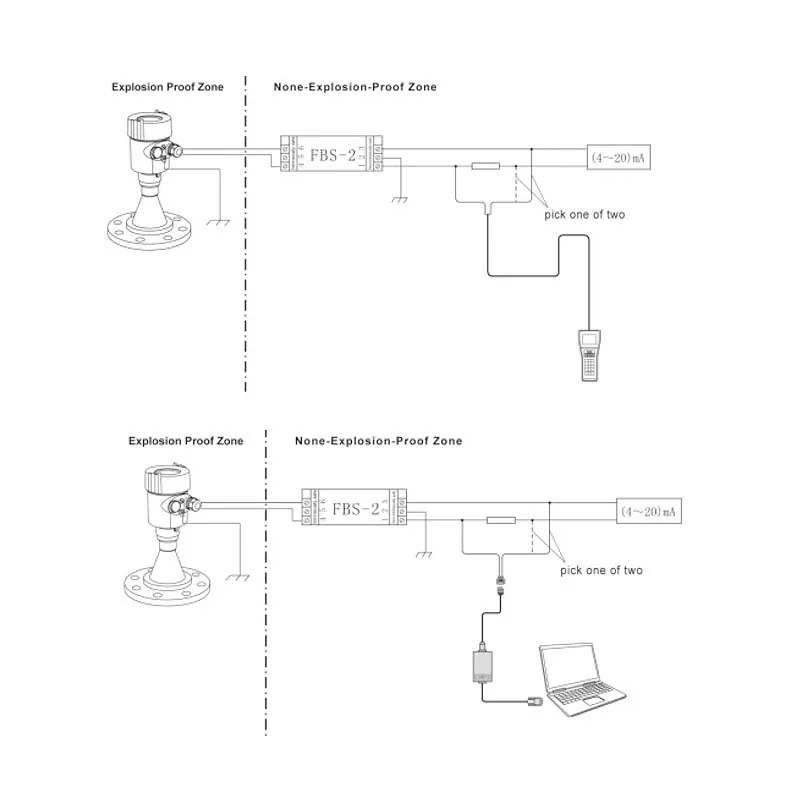

Radar Tank Level Gauge – Explosion Proof Connection

The intrinsic safety version (Exia IIc T6) features an aluminum die-cast housing with silicone rubber sealing to prevent sparks from circuit failures from escaping. It is suitable for continuous level measurement of flammable liquids under Exia IIc T6 conditions.

This instrument must be used with a safety barrier FBS-2, which serves as the power supply and ensures intrinsic safety. Key specifications of the barrier include:

Intrinsic safety: Exia IIC

Power supply voltage: 24V DC ± 5%

Short-circuit current: 135 mA

Operating current: 4–20 mA

Installation requirements:

All cables must be shielded; maximum length from barrier to sensor is 500 m.

Stray capacitance ≤ 0.1 μF/km, stray inductance ≤ 1 mH/km.

The instrument must be properly grounded.

Only approved associated devices may be used.

This design ensures reliable explosion-proof performance while maintaining precise radar tank level measurement under hazardous conditions.

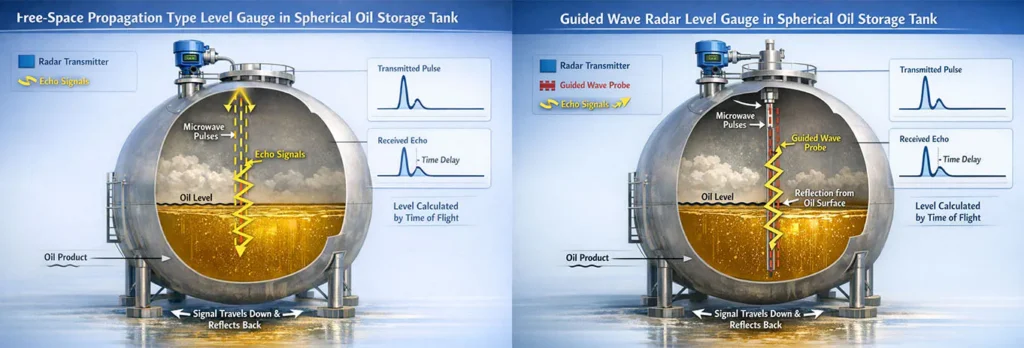

Radar Level Gauges – Working Principle

1. Space Propagation Radar (Non-contact Radar)

This type of radar level gauge emits microwave pulses from an antenna mounted above the tank toward the liquid surface. The pulses are reflected back to the antenna, and the travel time is measured to calculate the level. Non-contact radar is ideal for applications where the medium is corrosive, abrasive, or has high temperature or pressure. It is not affected by vapor, foam, or dust, making it suitable for a wide range of liquids and slurries.

2. Process Propagation Radar (Guided-wave Radar)

Guided-wave radar (GWR) uses a probe—such as a rod, cable, or coaxial waveguide—immersed in the medium to guide microwave pulses along its length. The pulse travels down the probe, reflects off the medium surface, and returns to the transmitter. GWR is highly precise and suitable for interfaces, low-dielectric liquids, and applications with limited space or turbulent surfaces. It is less sensitive to tank shape, vapor, or foam than non-contact radar.

Application of Radar Level Measurement

Radar level gauges are high-precision, non-contact instruments ideal for continuous level measurement of a wide range of liquid media, including water, industrial wastewater, hydrochloric acid, nitric acid, sulfuric acid, acidic and alkaline solutions, cement slurry, lime slurry, and various food slurries.

These instruments are widely applied across multiple industries, such as chemical processing, petroleum, water treatment, environmental protection, building materials, food and beverage, and pharmaceuticals, providing reliable, accurate, and maintenance-free level monitoring in both harsh and standard environments.

Instrumentos de medición de nivel Parámetro

| Aplicación | LPG (liquefied petroleum gas), Solid Particles, Powder |

| Rango de medición | 0-60m/0-120m |

| Connection | Flange and Threaded Connection(Customize Available) |

| Operation Temperature | -40℃ ~ 250℃(Special requirements can be customized) |

| Process Pressure | -0.1 ~ 2.0MPa (Flat flange) |

| Protective Class | IP67 |

| Salida de señal | 4-20mA/HART (Two-wire / Four)RS485/ Modbus |

| Fuente de alimentación | 2-wire(DC24V)/ 4-wire(DC24V /AC220V) |

| Outer Covering | Aluminum / Plastic / Stainless Steel |

| Display | Four-digit LCD, Programmable |

| Power Supply Voltage | Standard type: 16–26V DC (two-wire system) |

| Intrinsically safe type: 21.6–26.4 VDC | |

| Explosion-proof type: 22.8–26.4 VDC | |

| Four-wire system: 198–242 V AC, 110V AC | |

| Integration time | adjustable from 0 to 36 seconds |

Instrumentos de medición de nivel OEM/ODM

Customized Radar Level Gauge

We offer fully customizable radar level gauges tailored to your specific requirements. Options include adjustable measuring ranges, antenna types, frequency selection, explosion-proof configurations, and communication outputs such as 4–20 mA, HART, or Modbus.

Our team can design solutions for unique tank shapes, extreme temperatures, corrosive or abrasive media, and specialized industrial environments. OEM and ODM services also cover branding, labeling, and design modifications, ensuring each radar level sensor delivers precise, reliable performance and meets your operational and safety standards.

Recomendaciones de productos relacionados

A radar level gauge is a non-contact level measurement device that uses microwave signals to continuously measure liquid or solid levels with high accuracy, even in extreme industrial conditions.

From a manufacturer’s perspective, radar level gauges are recommended because they:

Deliver ±1–3 mm accuracy

Are unaffected by temperature, pressure, vapor, or dust

Require minimal maintenance due to no mechanical contact

Support long service life (10–15 years) in harsh environments

They are a core solution for industries requiring stable, long-term level measurement.

Radar level gauges are widely used in oil, chemical, and pharmaceutical plants because they provide safe, reliable, and contamination-free measurement.

Key benefits by industry:

Oil & Gas: Accurate tank gauging for crude oil, fuel, and LPG under high pressure

Chemical: Resistant to corrosive media, solvents, and aggressive vapors

Pharmaceutical: Non-contact measurement meets GMP and hygiene requirements

As a manufacturer, we design radar level gauges with PTFE, stainless steel (316L) wetted parts and ATEX / IECEx certifications to meet these industry standards.

An 80 GHz radar level gauge improves accuracy by using a narrow beam angle (as low as 3°), allowing precise measurement in narrow tanks and vessels with internal structures.

Technical advantages:

Better signal focusing

Reduced false echoes

Stable readings in foam, vapor, and turbulence

This makes 80 GHz radar ideal for pharmaceutical reactors, chemical vessels, and high-density storage tanks.

Yes. Radar level gauges are highly suitable for energy, power, and HVAC systems where reliability and continuous operation are critical.

Typical applications include:

Power plants: Boiler feedwater tanks, condensate tanks

Energy storage: Fuel oil and cooling water systems

HVAC systems: Chilled water tanks, thermal storage tanks

Our radar level gauges support continuous 24/7 operation, with output options such as 4–20 mA, HART, Modbus, ensuring easy integration with DCS and BMS systems.

Radar level gauges are designed to perform reliably in high-vibration and harsh outdoor environments, making them suitable for:

Marine & Shipping: Ballast water tanks, fuel tanks, cargo tanks

Automotive Industry: Chemical storage, coolant tanks, paint process systems

Mining & Environmental: Slurry tanks, tailings ponds, dust-heavy silos

With IP67/IP68 protection and rugged antenna designs, our radar level gauges maintain stable signals even under shock, vibration, and dust exposure.

When selecting a radar level gauge, manufacturers recommend evaluating:

Process medium: Liquid, solid, slurry, or foam

Operating conditions: Temperature, pressure, corrosion

Radar frequency: 26 GHz vs 80 GHz

Industry certifications: ATEX, IECEx, FDA, GMP (if applicable)

Communication protocol: 4–20 mA, HART, Modbus, Profibus

Choosing the correct configuration ensures measurement stability, compliance, and long-term cost efficiency.

Por qué elegir Instrava

Al elegir Instrava, obtiene un socio con un profundo conocimiento de las aplicaciones industriales y la experiencia necesaria para hacer frente a los retos operativos actuales.

Nuestro papel va más allá de los productos: respaldamos su éxito con soluciones fiables y un compromiso a largo plazo.

Innovación impulsada por la ingeniería

La innovación en Instrava se guía por necesidades industriales reales. Perfeccionamos continuamente nuestras tecnologías para hacer frente a los cambiantes retos operativos, garantizando un rendimiento práctico y fiable en entornos exigentes.

Personalización específica de la aplicación

Ofrecemos personalización a nivel de ingeniería para adaptarnos a las condiciones específicas del proceso. Desde el rango de medición y los materiales hasta las señales de salida y las opciones de instalación, nuestras soluciones están configuradas para adaptarse a aplicaciones reales.

Calidad y fiabilidad demostradas

La calidad y la fiabilidad son fundamentales en todos los productos Instrava. Fabricados bajo estrictos controles de calidad y sometidos a pruebas exhaustivas, nuestros instrumentos ofrecen un rendimiento preciso, estable y a largo plazo.

Capacidad global con apoyo local

Instrava combina la experiencia mundial en ingeniería con una asistencia local receptiva, lo que garantiza que nuestros socios se beneficien de una tecnología alineada internacionalmente y de un servicio regional puntual.

Amplia cartera de productos

Nuestra amplia cartera de instrumentos de medición y control nos permite dar respuesta a una amplia gama de necesidades industriales, proporcionando soluciones integradas a partir de una fuente única y fiable.

Asistencia técnica orientada a los socios

Trabajamos en estrecha colaboración con nuestros socios, desde el asesoramiento técnico hasta la asistencia posventa. Nos centramos en ofrecer soluciones que generen un valor duradero y contribuyan al éxito operativo a largo plazo.