Контроллеры газовой сигнализации

Главная » Продукция » Контроллеры газовой сигнализации » Контроллер газовых детекторов - промышленная панель мультигазовой сигнализации

Контроллер газовых детекторов - промышленная панель мультигазовой сигнализации

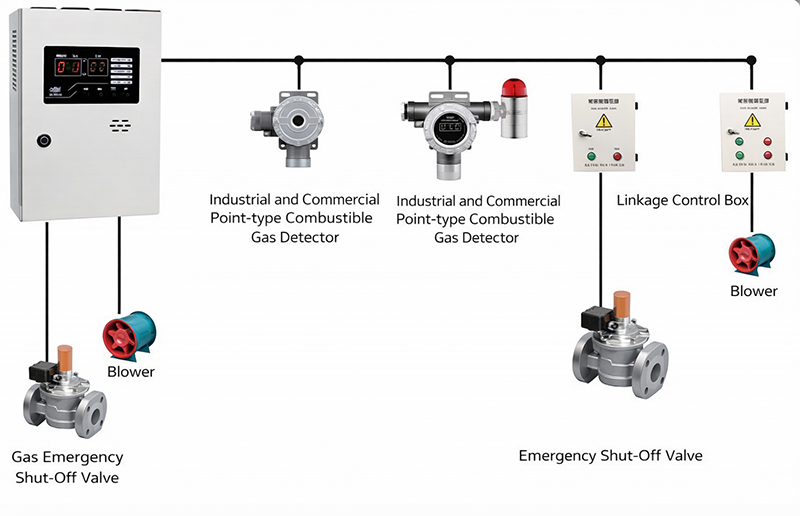

The Gas Detector Controller is a core industrial gas monitoring device designed to receive signals from multiple gas detectors, provide real-time alerts, and enable automated control in hazardous environments. It ensures workplace safety by monitoring combustible, toxic, and oxygen gases, making it ideal for chemical plants, petrochemical facilities, power stations, and metallurgical industries. This industrial-grade controller is built for continuous 24/7 operation, helping businesses maintain safety compliance and efficient gas management.

Gas Alarm Controllers Description

Gas Detector Controller Features

Large Capacity Data Logging: The controller can record up to 999 alarm events and 999 fault events, allowing easy historical data review. All records are retained even during power loss, ensuring reliable operational tracking.

IoT Connectivity & Remote Alerts: Supports voice calls, SMS, and WeChat notifications, enabling remote monitoring and instant alerting for critical gas alarms. Ideal for modern industrial IoT integration.

Battery Protection Function: When operating on backup power, the system automatically shuts down if the battery voltage is low, protecting the battery and extending its service life.

Intelligent Power Switching: Equipped with main and backup power supply switching, with clear status indicators for each power source to ensure uninterrupted operation.

Automatic Fault Detection: Continuously monitors system status, including:

Short circuit or disconnection in detector wiring

Main or backup power supply failures

Detector malfunction or failure

Reliable Industrial Performance: Designed for continuous 24/7 operation in harsh industrial environments, ensuring consistent safety monitoring.

Gas Detector Controller Applications

Polarity-Free Bus Connection: The system supports reversed connection without affecting operation, ensuring easy installation and reduced wiring errors.

Dual-Bus Capability: Combines communication and power on two bus lines, effectively saving construction and installation costs for industrial facilities.

Triple-Bus Configuration: Supports three bus lines, simplifying system expansion and renovation of existing networks.

Quad-Bus Operation: Enables asynchronous power supply, providing flexible and reliable power distribution for complex setups.

Mixed Bus Integration: Supports combining two-bus, three-bus, and four-bus configurations within the same system, offering installation flexibility and easy future scalability.

Gas Detector Controller Structure

Сайт Gas Detector Controller features a modular and industrial-grade design, providing flexibility, reliability, and ease of maintenance for industrial gas monitoring systems. Key structural highlights include:

Robust Housing: Durable metal or flame-retardant plastic enclosure ensures protection against dust, corrosion, and harsh industrial environments.

Modular Layout: Internal circuitry is arranged in separate functional modules for power management, signal processing, alarm control, and communication, allowing easy maintenance and scalable expansion.

Front Panel Interface: Equipped with digital display, operational buttons, and status indicator LEDs, enabling intuitive real-time monitoring of gas concentration and system status.

Flexible Wiring & Bus Support: Supports polarity-free bus connection, and multiple bus configurations (2-bus, 3-bus, 4-bus), allowing mixed installation in the same system for installation flexibility and cost-efficient upgrades.

Mounting Design: Compact wall-mounted configuration (210 × 300 × 70 mm) ensures easy installation in industrial control rooms or hazardous areas.

Integration Ready: Standardized upper computer communication interface (TTL/5V, MODBUS) allows seamless connection to SCADA or centralized monitoring systems.

Gas Detector Controller Indicator Light Description

Indicator Name | Color | Functionality | |

System | Master alarm | Red (color) | This indicator is always on when an alarm exists on the controller. |

Status | Systems | Greener | During normal operation, this indicator flashes (1HZ, lit for 0.5s) |

Total failure | Yellow (color) | This indicator is always on when there is a fault in the controller. | |

Anechoic | Greener | This indicator lights up when the controller performs the “Silencing” function during a system fault or alarm condition. | |

Mains normal | Greener | This indicator is always on when the main power supply of the controller is normal. | |

Main power failure (of an electrical system) | Yellow (color) | When the AC220V power supply is disconnected or the host power supply voltage is too low, this indicator light is always on. | |

Normal power reserve | Greener | This indicator is always on when the controller backup power is normal. | |

Backup power failure | Gellow (color) | This indicator is always on when the controller backup power supply is disconnected, short-circuited, or when the voltage is too low. | |

Linkage 1 | Greener | This indicator is always on when the 1st relay is activated. | |

Linkage 2 | Greener | This indicator is always on when the 2nd relay is activated. | |

Gas Alarm Controllers Parameter

| Параметр | Технические характеристики | Notes / Features |

|---|---|---|

| Operating Voltage | AC 220V (50Hz ±1%) | Standard industrial power supply |

| System Capacity | 1–4 points (SD8001A) / 1–8 points (SD8001B) | Flexible for small to medium-scale installations |

| Режим отображения | Digital tube | Clear real-time display of gas status |

| Load Capacity | DC 24V, max output current ≤ 0.5A (4-point) / 1A (8-point) | Supports multiple relay outputs |

| Alarm Mode | Sound and light alarm | Immediate visual and audible alerts |

| Power Consumption | ≤ 10W (excluding supporting equipment) | Energy-efficient industrial design |

| Backup Power Supply | 3.7V / 3000mAh ×2 (SD8001A) / ×4 (SD8001B) | Maintains operation during power outage |

| Signal Transmission | S-BUS | Reliable wired communication protocol |

| Расстояние передачи | ≤ 1500m | Supports long-distance detector connection |

| Installation | Wall-mounted | Простая установка и обслуживание |

| Overall Size | 210 × 300 × 70 mm | Compact industrial design |

| Product Weight | ~2.3 kg | Lightweight for wall-mounted installation |

| Upper Computer Interface | 1 communication interface (TTL/5V, standard MODBUS protocol) | Integration with SCADA / monitoring systems |

| Compatible Detectors | Hilti full range (except stand-alone detectors) | Wide compatibility with existing sensors |

| Операционная среда | Temp: -10℃ ~ +55℃, Humidity ≤ 93% RH, Pressure 86–106 KPa | Suitable for most industrial environments |

Gas Alarm Controllers OEM/ODM

Gas Detector Controller – OEM/ODM

We offer flexible OEM/ODM solutions for Gas Detector Controllers, providing industrial clients with fully customizable gas safety systems.

Customization Options:

Channel & Capacity: 1–16 channels or more, scalable for any facility size.

Alarm & Output: Custom relay outputs, audio-visual alarms, multi-level thresholds.

Bus & Wiring: 2-bus, 3-bus, 4-bus, or mixed configurations for flexible installation.

Power & Backup: Main/backup switching, battery options, and asynchronous supply.

Display & Interface: LCD/LED, buttons, MODBUS/RS485 for SCADA integration.

Environmental & Branding: Explosion-proof or waterproof designs, OEM labeling available.

Рекомендации по сопутствующим товарам

Our Gas Detector Controller is compatible with combustible gases, toxic gases (CO, H2S), and oxygen, supporting Hilti’s full range of detectors. It can be configured for multi-gas monitoring systems, making it ideal for chemical plants, petrochemical facilities, and industrial safety applications.

Yes. We provide OEM/ODM customization for channel number, alarm outputs, bus configuration (2-bus, 3-bus, 4-bus or mixed), display type, and communication interfaces (MODBUS, RS485). This ensures the controller fits any industrial gas safety system and integrates seamlessly with existing infrastructure.

The controller features robust industrial-grade housing, modular internal design, and backup power supply. It includes automatic fault detection for wiring issues, power failures, or detector malfunctions, ensuring continuous monitoring in industrial gas safety systems.

Our Gas Detector Controller supports IoT-based alerts, including voice calls, SMS, and WeChat notifications, and can integrate with SCADA systems via TTL/5V or MODBUS interfaces. This makes remote industrial gas monitoring simple and reliable for B2B clients.

Thanks to its modular design and multi-bus support, the controller allows flexible expansion. You can combine 2-bus, 3-bus, and 4-bus configurations in the same system, enabling cost-efficient upgrades or modifications without replacing the entire gas detection setup.

High reliability: 24/7 continuous operation with fault detection.

Customizable OEM/ODM solutions: Tailored to your industrial site and safety requirements.

Flexible integration: Works with a wide range of detectors and SCADA systems.

Advanced features: Large capacity data logging (999 alarms/faults), battery protection, and intelligent power switching.

These advantages make it an ideal choice for multi-gas controllers, industrial gas alarm panels, and comprehensive gas monitoring systems.

Почему стоит выбрать Instrava

Выбирая компанию Instrava, вы получаете партнера с глубоким пониманием промышленных применений и опытом, позволяющим решать современные производственные задачи.

Наша роль выходит за рамки продукции - мы поддерживаем ваш успех с помощью надежных решений и долгосрочных обязательств.

Инновации, управляемые инженерами

Инновации компании Instrava основаны на реальных промышленных требованиях. Мы постоянно совершенствуем наши технологии для решения возникающих производственных задач, обеспечивая практичную и надежную работу в сложных условиях.

Настройка под конкретное приложение

Мы обеспечиваем настройку на инженерном уровне для соответствия конкретным условиям процесса. От диапазона измерений и материалов до выходных сигналов и вариантов установки - наши решения настраиваются в соответствии с реальными условиями применения.

Проверенное качество и надежность

Качество и надежность являются основой каждого продукта Instrava. Изготовленные под строгим контролем качества и тщательно протестированные, наши приборы обеспечивают точную, стабильную и долговременную работу.

Глобальный потенциал с поддержкой на местах

Компания Instrava сочетает глобальный инженерный опыт с оперативной поддержкой на местах, обеспечивая нашим партнерам преимущества международных технологий и своевременного регионального обслуживания.

Широкий ассортимент продукции

Широкий ассортимент измерительных и контрольно-измерительных приборов позволяет нам удовлетворять широкий спектр промышленных потребностей, предлагая комплексные решения из одного надежного источника.

Инженерная поддержка, ориентированная на партнеров

Мы тесно сотрудничаем с нашими партнерами, начиная с технических консультаций и заканчивая послепродажным обслуживанием. Наше внимание сосредоточено на предоставлении решений, которые создают долгосрочную ценность и поддерживают долгосрочный операционный успех.