Level Measuring Instruments

Home » Products » Level Measuring Instruments » Electrode Level Sensor

Electrode Level Sensor

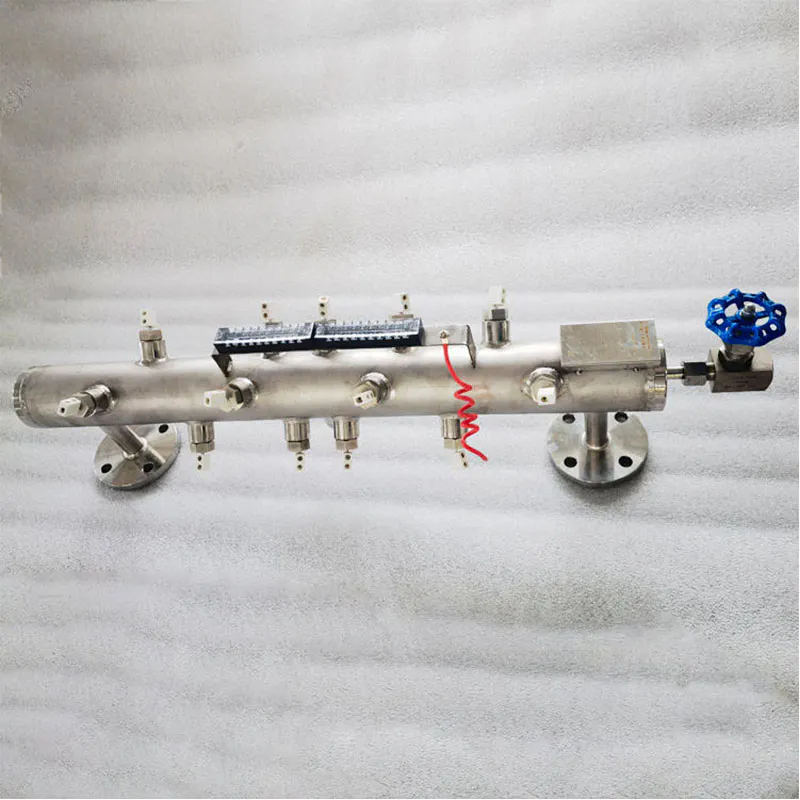

The electrode level gauge is a reliable, cost-effective solution for precise liquid level measurement across various industries. It utilizes a series of high-quality electrodes to detect liquid levels in tanks, vessels, or containers, ensuring accurate and consistent readings for water, oil, chemicals, and corrosive liquids. Explosion-proof models are available, making it ideal for hazardous environments.

The intelligent universal electric contact liquid level monitor is an advanced instrument combining a measuring cylinder, ultra-pure ceramic electrodes, and a display unit. It features red and green LED indicators to simulate steam (red) and water (green), clearly showing the liquid level position in the container. The device also offers over-limit alarms and output signals for remote monitoring and control.

This side-mounted electrode level gauge, with 4–20 mA output, is especially suitable for boiler water tanks, providing reliable and continuous liquid level measurement in demanding applications.

Level Measuring Instruments Description

Electrode Level Sensor-Features

This electrode level gauge combines advanced electric contact measurement technology with a side-mounted structure and 4–20 mA output, providing stable and reliable liquid level measurement for industrial applications such as boilers, water tanks, and process vessels.

The instrument supports dual display modes, integrating analog simulation and digital indication to clearly present real-time liquid level conditions. The display system allows flexible configuration of 6 to 19 measuring points, with each scale value adjustable through panel operation, enabling precise calibration according to site requirements.

Equipped with configurable sound and light alarm functions, the electrode level gauge provides multiple alarm modes for high and low level limits. Alarm points can be freely set within the full measurement range, supporting safe operation and timely response in critical processes.

The integrated 4–20 mA output ensures seamless signal transmission to PLC, DCS, or SCADA systems, enabling reliable remote monitoring and control. The side-mounted installation design simplifies mounting and maintenance, especially in limited space or existing tank and boiler systems.

With automatic judgment and tracking of water resistance, the electrode level sensor maintains accurate measurement even under changing medium conductivity. High fault tolerance and strong anti-interference capability effectively prevent false alarms caused by transient electrical disturbances.

Explosion-proof versions are available for hazardous and flammable environments, ensuring safe and stable operation in chemical, petrochemical, and power generation industries.

Electrode Water Level Sensor-Applications

Boiler Applications

Used for water level monitoring in industrial boilers and steam drums. The electrode level gauge accurately detects steam and water phases, helping prevent dry-burning and overfilling. With side-mounted installation, configurable alarms, and 4–20 mA output, it integrates easily with boiler control systems.

Water Tank Applications

Suitable for water tanks and storage vessels for clean or industrial water. Multiple measuring points and adjustable alarm settings support pump control and level alarms. The side-mounted design allows easy installation and reliable operation with PLC or SCADA systems.

Chemical Industry Applications

Applied in chemical and process tanks containing conductive liquids. Corrosion-resistant electrodes and optional explosion-proof versions ensure safe operation in harsh environments. Strong anti-interference performance and 4–20 mA output enable stable, long-distance signal transmission.

Electrode Water Level Gauge-Working Principle

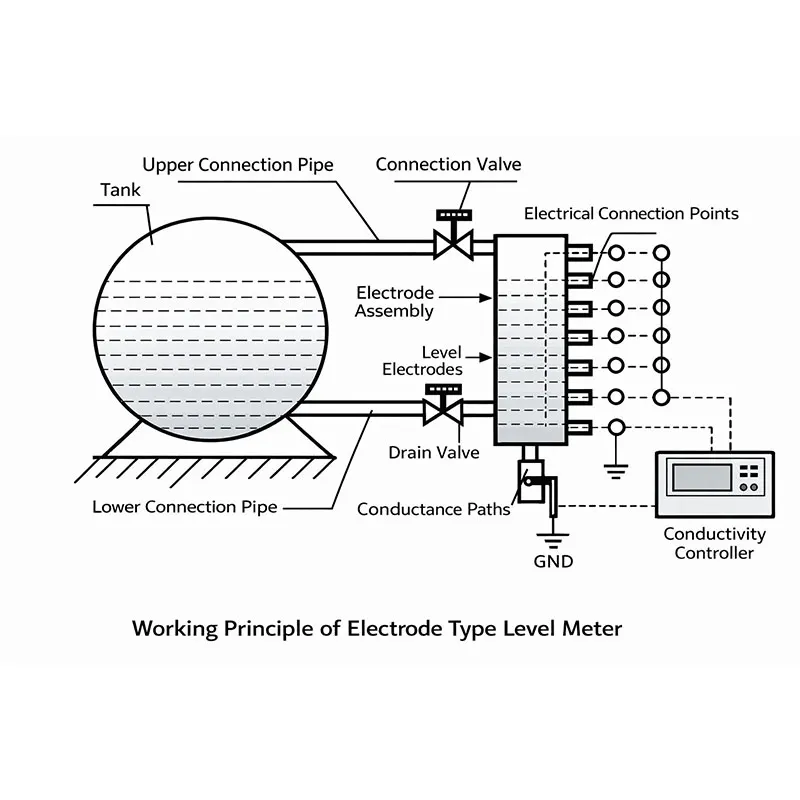

The electrode level gauge operates based on the significant difference in electrical conductivity between water and steam. The measuring cylinder detects liquid level changes by monitoring variations in electrical contact resistance.

When the electrodes are immersed in liquid, the medium’s low resistivity allows a relatively large current to flow once a voltage is applied. When the electrodes are above the liquid surface, the resistivity is much higher, resulting in a much smaller current. This clear current difference is used as a reliable level detection signal.

The detected signal is transmitted to the secondary instrument, where it is amplified, processed, and converted into display, alarm, and control outputs, enabling accurate liquid level indication and long-distance monitoring.

Level Electrode Sensor-Structure

Electrode rod or probe made from stainless steel or other corrosion-resistant materials to ensure long-term stability in different liquid media.

High-performance insulating material separates each electrode, preventing signal interference and ensuring accurate liquid level measurement.

Measuring cylinder design provides stable electrode positioning and reliable contact detection under varying process conditions.

Housing options include standard, explosion-proof, or customized configurations to meet different installation and safety requirements.

Supports various probe lengths, diameters, and mounting structures, allowing flexible adaptation to different tank sizes, boiler systems, and application environments.

Level Measuring Instruments Parameter

| Parameter | Specification |

|---|---|

| Liquid water resistance range | 0–500 kΩ, automatic resistance tracking |

| Output signal | 0–10 mA (RL < 1 kΩ) / 4–20 mA (RL < 500 Ω), linear, isolated |

| Alarm output contact | AC 220 V, 1 A |

| Backup power supply | Built-in DC battery, ≥ 1 hour operation |

| Power supply | AC 220 V ±10%, 50 Hz ±1 Hz |

| Ambient temperature | –10 °C to +45 °C |

| Relative humidity | ≤ 85% |

| Panel cutout dimensions | 152 +1 × 76 +1 mm or 152 +1 × 152 +1 mm |

| Instrument dimensions | 173 × 225 × 80 mm |

Level Measuring Instruments OEM/ODM

Electrode Level Sensor – OEM / ODM Customization

We provide professional OEM and ODM customization services for electrode level sensors to meet diverse industrial and application-specific requirements. Backed by manufacturing experience and strict quality control, our solutions are designed for long-term stable operation in demanding environments.

Customization options include measuring range, number of electrodes, probe length, and electrode spacing based on tank height, boiler structure, or process conditions. Output signals such as 4–20 mA or other analog formats can be configured to ensure seamless integration with PLC, DCS, or SCADA systems.

Material selection is available for both electrodes and housings to accommodate corrosive liquids, high temperatures, or special media. Standard industrial enclosures and explosion-proof versions can be supplied for hazardous areas.

We also support customized alarm logic, display layout, mounting structures, and panel dimensions to match project specifications or existing installations. From prototype development to batch production, our OEM / ODM services ensure consistent performance, reliable delivery, and full technical support throughout the product lifecycle.

Related Product Recommendations

The electrode level gauge detects liquid level based on the difference in electrical conductivity between liquid and air/steam. When electrodes are immersed in liquid, they complete an electrical circuit, sending a signal to the display or control system. Compared with ultrasonic or radar sensors, electrode liquid level sensors are simpler, cost-effective, and ideal for conductive liquids such as water, boiler water, and chemical solutions. Non-contact technologies may suit corrosive or high-temperature media but are generally more expensive.

Selecting the appropriate electrode level gauge involves:

Measurement range & electrode count: More electrodes allow finer resolution.

Tank/boiler dimensions & mounting: Side-mounted sensors are ideal for retrofits.

Medium type: Choose corrosion-resistant electrode materials for chemical liquids.

Output signal: Standard 4–20 mA for PLC/DCS integration, optional 0–10 mA or relay alarms.

Safety: Explosion-proof electrode level sensors are required for flammable or hazardous environments.

| Application | Recommended Sensor | Key Features |

|---|---|---|

| Boiler water | Boiler-specific electrode level gauge | Steam/water phase detection, LED indicators, alarms |

| Water tank | Standard electrode liquid level sensor | Multi-point measurement, 4–20 mA output, side mount |

| Chemical tank | Explosion-proof electrode level sensor | Corrosion-resistant, anti-interference, certified housing |

Yes. Explosion-proof and high-temperature electrode level gauges are available. Electrode materials like stainless steel, Hastelloy, or titanium can resist corrosion. High-performance insulation ensures accurate measurement in challenging environments. For high-temperature or chemical media, ceramic electrodes or specialized housing designs are recommended, ensuring long-term reliability.

Typical accuracy is ±5–10 mm, depending on electrode spacing and installation. Reliability factors include medium conductivity, electrode spacing, turbulence, and electrical interference. Advanced models feature automatic water resistance tracking, strong anti-interference design, and fault tolerance to maintain stable and accurate readings in boilers, water tanks, or chemical tanks.

| Factor | Impact | Mitigation |

|---|---|---|

| Low conductivity | Weak signal, possible misreading | Use higher voltage or sensitive electronics |

| Foam or vapor | False electrode contact | Proper electrode type and mounting |

| Electrical interference | False alarms | Shielding and filtering circuits |

Electrode level gauges offer flexible output options:

Analog: 4–20 mA standard for PLC/DCS/SCADA integration

0–10 mA or 0–5 V for specialized control systems

Relay contacts for alarms or interlocks

Optional digital communication for smart instrumentation

This allows seamless integration into monitoring and process control systems while maintaining real-time accuracy.

We provide full OEM and ODM services for electrode liquid level sensors, including:

Custom measurement ranges, number of electrodes, probe length, and spacing

Material selection for corrosive, high-temperature, or specialized media

Standard or explosion-proof enclosures for hazardous environments

Output customization: 4–20 mA, 0–10 mA, relay, or alarm logic

Display and panel configuration: LED/LCD, analog + digital display, remote monitoring

Our factory supports prototype development and batch production, ensuring stable performance, high reliability, and full technical support across all industrial applications.

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.