Gas Detectors

Home » Products » Gas Detectors » Fixed Combustible Gas Detector

Fixed Combustible Gas Detector

Our fixed gas detector is a high-performance industrial solution designed for continuous, real-time monitoring of combustible and toxic gases in professional work environments. Available in both intelligent bus systems and branch line systems, it can be integrated with compatible controllers to create a complete fixed gas alarm detection system, ideal for factories, chemical plants, warehouses, and other industrial facilities.

This fixed multi gas detector monitors target gases—including methane (CH₄), propane (C₃H₈), hydrogen sulfide (H₂S), carbon monoxide (CO), and other toxic or combustible gases—providing accurate, real-time concentration readings directly on-site. When gas levels exceed preset thresholds, the system immediately triggers audible and visual alarms, ensuring fast response and workplace safety.

Enterprise clients can monitor the operational status of each fixed toxic gas detector via the controller, including normal operation, fault conditions, and alarm events. Critical settings, such as zero-point calibration, gas concentration calibration, and high/low alarm limits, can be easily configured through the controller or an infrared remote.

Designed and certified according to national safety standards, this fixed combustible gas detector and gas detectors 4 gases solution delivers high precision, stability, and low-maintenance operation. Its modular design supports customized configurations for industrial clients seeking reliable fixed H₂S gas detectors, fixed gas detectors for CH₄ or C₃H₈, or fully integrated multi-gas detection systems.

With intelligent monitoring, remote configuration, and seamless integration with safety management systems, this fixed gas detector for home/industrial applications ensures maximum safety and operational efficiency, making it the preferred choice for B2B industrial clients worldwide.

Gas Detectors Description

Fixed Gas Detector Features

Compatible with Bus and 4-20mA Systems – Supports both intelligent bus systems and 4-20mA branch line systems, providing flexible integration and easy expansion for industrial fixed gas detector networks.

Serviceable Sensor Modules – Modular sensor design allows easy maintenance and replacement, reducing operational costs and downtime for industrial applications.

Infrared Remote Control – Configure and calibrate detectors on-site without opening the device, enhancing convenience and safety during maintenance.

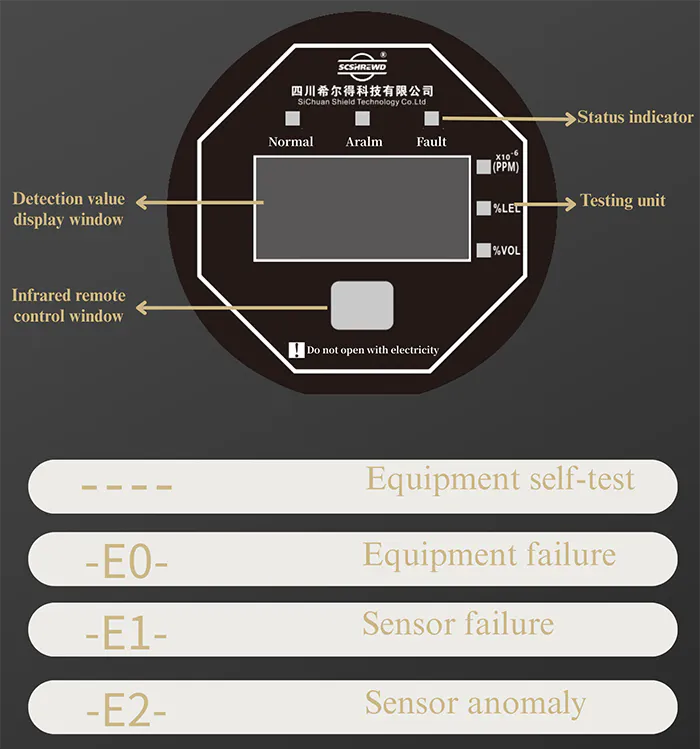

Digital Display – Real-time gas concentration readings and device status are clearly shown on the digital tube display for immediate assessment.

Built-in Control Output – Supports direct linkage to on-site alarms, fans, or valves, enabling automated safety response when gas levels exceed thresholds.

Dual Wiring Structure – Simplifies field installation and wiring, reducing engineering complexity and installation time.

Integrated Temperature Monitoring – Ensures accurate and reliable gas detection even under varying environmental temperatures, maintaining performance in harsh industrial conditions.

Combustible Gas Detector-Detectable Gas Types

Our fixed gas detector can be configured with multiple sensor modules to detect a wide range of toxic and combustible gases, making it suitable for diverse industrial applications. The detectors can be customized as fixed multi gas detectors to meet specific site safety requirements.

| Gas Type | Chemical Formula | Category | Detection Range | Typical Industrial Applications |

|---|---|---|---|---|

| Methane | CH₄ | Combustible | 0-100% LEL | Natural gas pipelines, chemical plants, refineries |

| Propane | C₃H₈ | Combustible | 0-100% LEL | LPG storage, fuel stations, industrial kitchens |

| Hydrogen Sulfide | H₂S | Toxic | 0-100 ppm | Petroleum processing, wastewater treatment, chemical manufacturing |

| Carbon Monoxide | CO | Toxic | 0-500 ppm | Boiler rooms, underground garages, industrial plants |

| Oxygen | O₂ | Oxygen deficiency | 0-25% | Confined spaces, storage tanks, chemical facilities |

| Ammonia | NH₃ | Toxic | 0-100 ppm | Cold storage, refrigeration systems, food processing plants |

| Optional Multi-Gas | – | Combustible / Toxic | Customized | Industrial workshops, laboratories, hazardous material storage |

Supports simultaneous detection of multiple gases with a single fixed multi gas detector system.

Modular sensor design allows flexible selection and replacement according to site-specific requirements.

Accurate and reliable measurements for safety compliance and regulatory reporting.

Ideal for integration with industrial safety management systems, enabling real-time monitoring, alerts, and remote control.

Fixed Gas Detectors-Smart App Alerts

Our fixed gas detector can be connected to a dedicated mobile app, providing intelligent and real-time safety monitoring for industrial sites. By downloading and logging into the app, enterprise users receive instant notifications whenever gas concentrations exceed preset safety thresholds.

Real-Time Alerts – Receive SMS and phone call notifications immediately when the detector senses hazardous gas leaks.

Centralized Monitoring – Monitor multiple fixed multi gas detectors across different locations from a single interface.

Customizable Alarm Settings – Set high/low concentration limits and alarm triggers according to site-specific safety requirements.

Historical Data Access – View past gas concentration trends and alarm events to support safety audits and regulatory compliance.

Enhanced Safety for Industrial Clients – The app ensures that on-site personnel and facility managers are alerted immediately, reducing risk and enabling prompt preventive action.

Fixed Combustible Gas Detector-Infrared Remote Operation

Our fixed gas detector supports advanced remote control features, enabling industrial clients to configure and manage devices efficiently without interrupting operations.

Infrared Remote Operation – Perform on-site configuration, zero-point calibration, and alarm parameter adjustments without opening the detector cover, ensuring safety and convenience.

Remote Monitoring and Control – Adjust detector settings, view real-time gas concentration data, and manage multiple fixed multi gas detectors from a central location.

Customizable Parameters – High/low alarm thresholds, calibration settings, and operational modes can be modified remotely to meet site-specific requirements.

Technical Support – For more detailed operations and advanced remote control options, please contact our technical support team.

This fixed toxic gas detector and fixed combustible gas detector solution provides flexible, safe, and efficient remote management, ideal for B2B clients managing multiple industrial sites.

Gas Detectors Parameter

| Parameter | Specification |

|---|---|

| Detectable Gases | Methane (CH₄), Propane (C₃H₈), and other combustible or toxic gases |

| Detection Principle | Catalytic combustion, Infrared, Electrochemical, Semiconductor, or PID (Photoionization Detector) |

| Sampling Method | Diffusion |

| Measurement Range | 3–100% LEL (adjustable for other gases) |

| Default Alarm Thresholds | Low: 25% LEL, High: 50% LEL |

| Alarm Accuracy | ±3% F.S |

| Response Time | Combustible gases: ≤30s (T90), Toxic gases: ≤60s (T90) |

| Power Consumption | ≤3W (DC 24V) |

| Protection Rating | IP66 (dustproof & waterproof) |

| Explosion-Proof Rating | ExdⅡCT6Gb |

| Communication Method | S-BUS intelligent bus and 4-20mA branch line systems |

| External Control Output | 1 passive switch signal, contact capacity: 1A/AC220V or 1A/DC24V |

| Sensor Lifespan | 3 years (typical for catalytic sensors) |

| Storage Temperature | -25℃ to +55℃ |

| Operating Environment | Temperature: -40℃ to +70℃, Relative Humidity: ≤93% RH, Pressure: 86–106 kPa |

| Explosion-Proof Cable Entry | Conductor diameter: 9–10 mm |

| Thread Size | G3/4 |

| Weight | Approx. 880 g |

| Dimensions | 156.5 × 150.5 × 76.5 mm |

Gas Detectors OEM/ODM

Our fixed gas detector and fixed multi gas detector solutions offer extensive customization options to meet the specific safety and operational requirements of industrial clients:

Gas Detection Configuration – Customize single-gas or multi-gas detection systems according to site-specific hazards, including combustible gases like CH₄/C₃H₈ and toxic gases like H₂S/CO.

Alarm and Output Options – Configure high/low alarm thresholds, audible/visual alarms, relay outputs, or app notifications to match industrial safety protocols.

Installation Flexibility – Support wall-mounted, ceiling-mounted, or pipe-mounted installations for diverse industrial environments.

Communication Protocols – Compatible with S-BUS intelligent bus, 4-20mA branch line systems, Modbus, LoRa, or other protocols for integration with industrial monitoring and SCADA systems.

Appearance and Branding – Custom housing colors, panel designs, and company logos for OEM branding.

Extended Sensor Options – Modular sensors allow selection of detection principles (catalytic, infrared, electrochemical, PID) based on the specific gas hazards and operational conditions.

Tailored System Integration – Supports integration with centralized control systems, remote monitoring platforms, and smart industrial safety networks.

This flexible fixed toxic gas detector and fixed combustible gas detector solution ensures that industrial clients receive a fully customized, reliable, and maintenance-efficient gas detection system tailored to their operational and safety needs.

Related Product Recommendations

Our fixed gas detectors can monitor a wide range of gases, including combustible gases such as methane (CH₄) and propane (C₃H₈), as well as toxic gases like hydrogen sulfide (H₂S) and carbon monoxide (CO). We also offer fixed multi gas detectors capable of detecting up to 4 gases simultaneously, making them ideal for factories, chemical plants, warehouses, and other industrial sites.

The fixed toxic gas detector is integrated with controllers that provide real-time on-site monitoring. When gas concentrations exceed preset thresholds, the system triggers audible and visual alarms. Additionally, our smart app can send instant SMS and phone notifications, ensuring rapid response and safety compliance for B2B industrial clients.

Yes, our fixed combustible gas detectors support S-BUS intelligent bus and 4-20mA branch line systems, as well as Modbus and other industrial communication protocols. This allows seamless integration with SCADA systems, remote monitoring platforms, and enterprise safety management networks.

Our fixed multi gas detectors feature modular, serviceable sensors, which can be easily replaced or calibrated using an infrared remote or controller without opening the device. Typical sensor lifespan is 3 years (for catalytic sensors), reducing downtime and maintenance costs for industrial clients.

Absolutely. Each fixed gas detector allows configuration of high and low alarm thresholds, zero-point calibration, and concentration calibration. This flexibility ensures the detectors meet specific safety requirements for different industrial applications, including fixed H₂S gas detectors for petroleum processing or gas detectors 4 gases for multi-gas monitoring scenarios.

Yes. Our fixed toxic and combustible gas detectors are built to industrial standards with IP66 protection and ExdⅡCT6Gb explosion-proof ratings. They operate reliably in temperatures ranging from -40℃ to +70℃, with high humidity tolerance (≤93% RH), making them ideal for factories, chemical plants, refineries, and other challenging B2B industrial environments.

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.