Gas Alarm Controllers

Home » Products » Gas Alarm Controllers » Gas Detector Controller – Industrial Multi-Gas Alarm Panel

Gas Detector Controller – Industrial Multi-Gas Alarm Panel

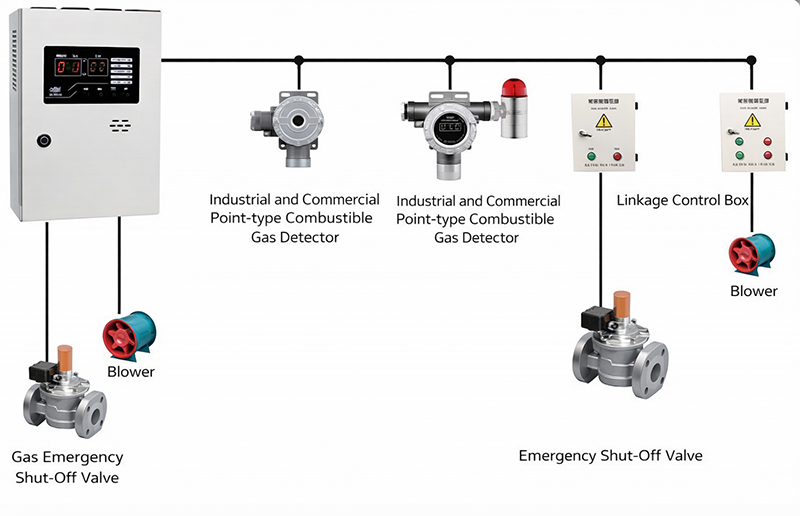

The Gas Detector Controller is a core industrial gas monitoring device designed to receive signals from multiple gas detectors, provide real-time alerts, and enable automated control in hazardous environments. It ensures workplace safety by monitoring combustible, toxic, and oxygen gases, making it ideal for chemical plants, petrochemical facilities, power stations, and metallurgical industries. This industrial-grade controller is built for continuous 24/7 operation, helping businesses maintain safety compliance and efficient gas management.

Gas Alarm Controllers Description

Gas Detector Controller Features

Large Capacity Data Logging: The controller can record up to 999 alarm events and 999 fault events, allowing easy historical data review. All records are retained even during power loss, ensuring reliable operational tracking.

IoT Connectivity & Remote Alerts: Supports voice calls, SMS, and WeChat notifications, enabling remote monitoring and instant alerting for critical gas alarms. Ideal for modern industrial IoT integration.

Battery Protection Function: When operating on backup power, the system automatically shuts down if the battery voltage is low, protecting the battery and extending its service life.

Intelligent Power Switching: Equipped with main and backup power supply switching, with clear status indicators for each power source to ensure uninterrupted operation.

Automatic Fault Detection: Continuously monitors system status, including:

Short circuit or disconnection in detector wiring

Main or backup power supply failures

Detector malfunction or failure

Reliable Industrial Performance: Designed for continuous 24/7 operation in harsh industrial environments, ensuring consistent safety monitoring.

Gas Detector Controller Applications

Polarity-Free Bus Connection: The system supports reversed connection without affecting operation, ensuring easy installation and reduced wiring errors.

Dual-Bus Capability: Combines communication and power on two bus lines, effectively saving construction and installation costs for industrial facilities.

Triple-Bus Configuration: Supports three bus lines, simplifying system expansion and renovation of existing networks.

Quad-Bus Operation: Enables asynchronous power supply, providing flexible and reliable power distribution for complex setups.

Mixed Bus Integration: Supports combining two-bus, three-bus, and four-bus configurations within the same system, offering installation flexibility and easy future scalability.

Gas Detector Controller Structure

The Gas Detector Controller features a modular and industrial-grade design, providing flexibility, reliability, and ease of maintenance for industrial gas monitoring systems. Key structural highlights include:

Robust Housing: Durable metal or flame-retardant plastic enclosure ensures protection against dust, corrosion, and harsh industrial environments.

Modular Layout: Internal circuitry is arranged in separate functional modules for power management, signal processing, alarm control, and communication, allowing easy maintenance and scalable expansion.

Front Panel Interface: Equipped with digital display, operational buttons, and status indicator LEDs, enabling intuitive real-time monitoring of gas concentration and system status.

Flexible Wiring & Bus Support: Supports polarity-free bus connection, and multiple bus configurations (2-bus, 3-bus, 4-bus), allowing mixed installation in the same system for installation flexibility and cost-efficient upgrades.

Mounting Design: Compact wall-mounted configuration (210 × 300 × 70 mm) ensures easy installation in industrial control rooms or hazardous areas.

Integration Ready: Standardized upper computer communication interface (TTL/5V, MODBUS) allows seamless connection to SCADA or centralized monitoring systems.

Gas Detector Controller Indicator Light Description

Indicator Name | Color | Functionality | |

System | Master alarm | Red (color) | This indicator is always on when an alarm exists on the controller. |

Status | Systems | Greener | During normal operation, this indicator flashes (1HZ, lit for 0.5s) |

Total failure | Yellow (color) | This indicator is always on when there is a fault in the controller. | |

Anechoic | Greener | This indicator lights up when the controller performs the “Silencing” function during a system fault or alarm condition. | |

Mains normal | Greener | This indicator is always on when the main power supply of the controller is normal. | |

Main power failure (of an electrical system) | Yellow (color) | When the AC220V power supply is disconnected or the host power supply voltage is too low, this indicator light is always on. | |

Normal power reserve | Greener | This indicator is always on when the controller backup power is normal. | |

Backup power failure | Gellow (color) | This indicator is always on when the controller backup power supply is disconnected, short-circuited, or when the voltage is too low. | |

Linkage 1 | Greener | This indicator is always on when the 1st relay is activated. | |

Linkage 2 | Greener | This indicator is always on when the 2nd relay is activated. | |

Gas Alarm Controllers Parameter

| Parameter | Specification | Notes / Features |

|---|---|---|

| Operating Voltage | AC 220V (50Hz ±1%) | Standard industrial power supply |

| System Capacity | 1–4 points (SD8001A) / 1–8 points (SD8001B) | Flexible for small to medium-scale installations |

| Display Mode | Digital tube | Clear real-time display of gas status |

| Load Capacity | DC 24V, max output current ≤ 0.5A (4-point) / 1A (8-point) | Supports multiple relay outputs |

| Alarm Mode | Sound and light alarm | Immediate visual and audible alerts |

| Power Consumption | ≤ 10W (excluding supporting equipment) | Energy-efficient industrial design |

| Backup Power Supply | 3.7V / 3000mAh ×2 (SD8001A) / ×4 (SD8001B) | Maintains operation during power outage |

| Signal Transmission | S-BUS | Reliable wired communication protocol |

| Transmission Distance | ≤ 1500m | Supports long-distance detector connection |

| Installation | Wall-mounted | Easy installation and maintenance |

| Overall Size | 210 × 300 × 70 mm | Compact industrial design |

| Product Weight | ~2.3 kg | Lightweight for wall-mounted installation |

| Upper Computer Interface | 1 communication interface (TTL/5V, standard MODBUS protocol) | Integration with SCADA / monitoring systems |

| Compatible Detectors | Hilti full range (except stand-alone detectors) | Wide compatibility with existing sensors |

| Operating Environment | Temp: -10℃ ~ +55℃, Humidity ≤ 93% RH, Pressure 86–106 KPa | Suitable for most industrial environments |

Gas Alarm Controllers OEM/ODM

Gas Detector Controller – OEM/ODM

We offer flexible OEM/ODM solutions for Gas Detector Controllers, providing industrial clients with fully customizable gas safety systems.

Customization Options:

Channel & Capacity: 1–16 channels or more, scalable for any facility size.

Alarm & Output: Custom relay outputs, audio-visual alarms, multi-level thresholds.

Bus & Wiring: 2-bus, 3-bus, 4-bus, or mixed configurations for flexible installation.

Power & Backup: Main/backup switching, battery options, and asynchronous supply.

Display & Interface: LCD/LED, buttons, MODBUS/RS485 for SCADA integration.

Environmental & Branding: Explosion-proof or waterproof designs, OEM labeling available.

Related Product Recommendations

Our Gas Detector Controller is compatible with combustible gases, toxic gases (CO, H2S), and oxygen, supporting Hilti’s full range of detectors. It can be configured for multi-gas monitoring systems, making it ideal for chemical plants, petrochemical facilities, and industrial safety applications.

Yes. We provide OEM/ODM customization for channel number, alarm outputs, bus configuration (2-bus, 3-bus, 4-bus or mixed), display type, and communication interfaces (MODBUS, RS485). This ensures the controller fits any industrial gas safety system and integrates seamlessly with existing infrastructure.

The controller features robust industrial-grade housing, modular internal design, and backup power supply. It includes automatic fault detection for wiring issues, power failures, or detector malfunctions, ensuring continuous monitoring in industrial gas safety systems.

Our Gas Detector Controller supports IoT-based alerts, including voice calls, SMS, and WeChat notifications, and can integrate with SCADA systems via TTL/5V or MODBUS interfaces. This makes remote industrial gas monitoring simple and reliable for B2B clients.

Thanks to its modular design and multi-bus support, the controller allows flexible expansion. You can combine 2-bus, 3-bus, and 4-bus configurations in the same system, enabling cost-efficient upgrades or modifications without replacing the entire gas detection setup.

High reliability: 24/7 continuous operation with fault detection.

Customizable OEM/ODM solutions: Tailored to your industrial site and safety requirements.

Flexible integration: Works with a wide range of detectors and SCADA systems.

Advanced features: Large capacity data logging (999 alarms/faults), battery protection, and intelligent power switching.

These advantages make it an ideal choice for multi-gas controllers, industrial gas alarm panels, and comprehensive gas monitoring systems.

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.