Instrumentos de medición de nivel

Inicio » Productos » Instrumentos de medición de nivel » Indicador de nivel de vidrio / Indicador de nivel de vidrio

Indicador de nivel de vidrio / Indicador de nivel de vidrio

The Glass Level Gauge is a direct-reading liquid level measuring instrument designed for continuous visual monitoring of liquid levels in tanks, vessels, and pipelines. By utilizing a transparent glass tube or flat glass panel, operators can clearly observe the actual liquid level in real time, ensuring safe and reliable process control.

✔ Direct visual indication

✔ Simple structure, no power required

✔ Suitable for harsh industrial environments

Instrumentos de medición de nivel Descripción

Glass Level Gauge-Product Features

1️⃣ Direct Visual Liquid Level Indication

The glass level gauge provides a true, real-time visual indication of the actual liquid level inside tanks and vessels. Unlike electronic sensors, it displays the liquid position directly through the sight glass, allowing operators to immediately identify level changes, foaming, or abnormal conditions.

2️⃣ Integrated Quick Shut-Off Safety Device

Designed with a built-in quick shut-off mechanism, the gauge automatically isolates the process in the event of glass breakage or leakage. This safety feature effectively prevents vapor or liquid escape, enhancing operator safety and minimizing process risks.

3️⃣ Robust & Practical Structural Design

The sight glass level gauge features a compact and well-engineered structure, ensuring easy installation on existing tanks or pipelines. Standard process connections allow for fast commissioning, while the modular design simplifies routine inspection and part replacement.

4️⃣ Low Maintenance & Cost-Effective Operation

With no power supply or signal components required, the glass level gauge offers long-term stable operation with minimal maintenance. The durable glass and metal components reduce downtime and spare part costs, making it an economical solution for continuous level monitoring.

Sight Glass Level Gauge-Applications / Industries

The glass plate liquid level gauge is widely used in various industrial systems where reliable and direct liquid level monitoring is required. Typical applications include:

Chemical & Petrochemical Plants

Ideal for corrosive or hazardous liquids. Provides real-time visual monitoring of reaction tanks, storage vessels, and process systems.Boilers & Steam Systems

Ensures accurate water level observation in boiler drums and steam vessels. High-temperature and pressure-resistant design with integrated safety protection.Water Treatment Systems

Enables continuous monitoring of water levels in filtration, storage, and circulation systems. Simple structure allows easy installation and maintenance.Food & Pharmaceutical Processing

Supports observation of liquid levels in clean and sanitary environments. Compatible with hygienic media and easy to sanitize.Oil & Gas Storage and Transportation

Provides safe and reliable monitoring for oil tanks, fuel storage, and pipelines. Robust design ensures stable operation under varying pressures and temperatures.

Glass Sight Glass Level Gauge-Working Principle

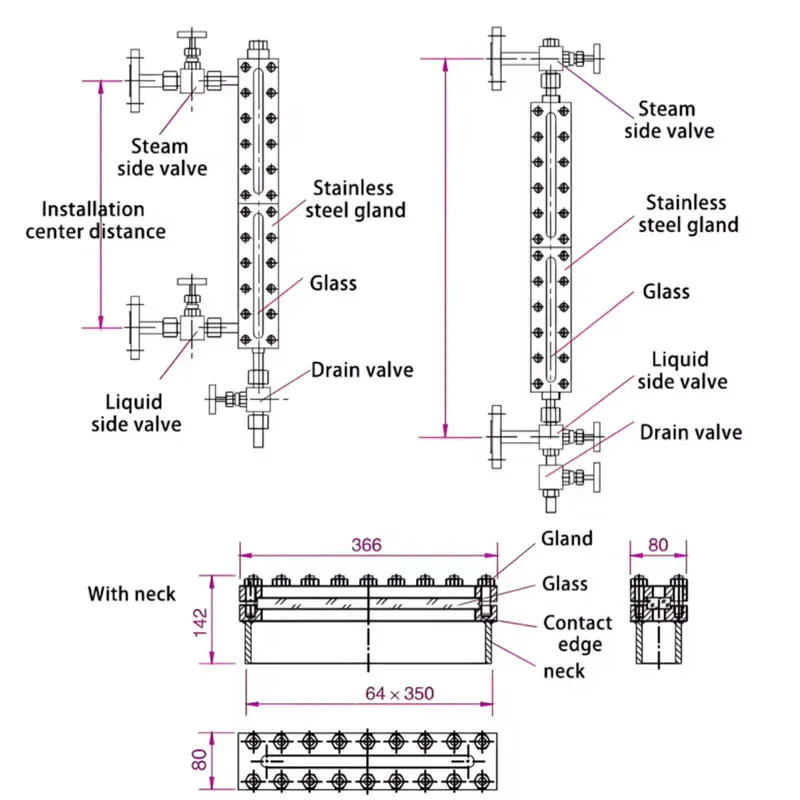

In general industrial systems such as water treatment units, oil tanks, and auxiliary process vessels, the glass plate liquid level gauge provides a simple and reliable method for liquid level observation. Once installed on the tank, the gauge chamber and vessel form a communicating structure, ensuring consistent liquid level indication.

The liquid level can be directly observed through the glass plate without external power supply or signal processing. The mechanical design allows stable operation under continuous service conditions, making it suitable for routine level monitoring across a wide range of industrial processes.

Installed on chemical tanks or reactors, the glass plate liquid level gauge forms a communicating vessel with the process system, enabling direct visual level observation. In case of glass rupture, the built-in safety steel ball automatically seals the flow path to reduce hazardous media leakage.

Connected to the steam and water spaces of the boiler drum, the gauge directly displays the actual boiler water level in real time. If the glass plate breaks, the automatic shut-off mechanism immediately isolates steam and water flow to ensure safe operation.

Level Gauge Sight Glass-Structure Comparison

| Tipo | Structural Characteristics | Visual Effect | Typical Applications |

|---|---|---|---|

| Transparent Type | Double transparent glass plates with sealed chamber; simple mechanical structure | Direct and clear observation of actual liquid level and medium | Water, oil, non-toxic liquids, general industrial tanks |

| Reflex Type | Prismatic glass surface with reflective structure; light reflection enhances contrast | Liquid appears dark, vapor area appears bright | Steam systems, boilers, high-temperature liquids |

| Mirror-Type | Flat glass with internal mirror-assisted visual enhancement | Improved readability under limited lighting conditions | Medium-pressure vessels, indoor or low-light environments |

Instrumentos de medición de nivel Parámetro

| Custom | Support OEM/ODM |

| Medio | líquido o material en general o ligeramente corroído |

| Rango de medición | 5m, 10m, 15m, 30m, 50m, 60m,120m |

| Material del transductor | Cerámica |

| Error de medición | 0.5%. 1.0% |

| Precisión | ±3 mm (superficie del agua en calma y sin olas) |

| Resolución | 3~5mm o 0.1% (tomar valor grande) |

| Modo de visualización | LCD, los parámetros se pueden ajustar a través de los botones del panel |

| Salida de señal | 4~20mADC |

| Salida de relé | 2 grupos son opcionales, y el estado del relé es programable |

| Temperatura de trabajo | -25~80 ℃ |

| Interfaz de comunicación | RS232, RS485/Modbus |

| Interfaz eléctrica | M20*1.5, 1/2″PT |

| Grado antideflagrante | ExiaIICT6Ga/ExdIICT6Gb |

| Nivel de protección: | IP67 |

| Material del caparazón: | plásticos técnicos, aleación de aluminio, SS304 |

| Temperatura ambiente: | (meter) -20-60 ℃; (sensor) -20~80 ℃ |

| Humedad relativa | 95% |

Instrumentos de medición de nivel OEM/ODM

Sight Glass Level Gauge – OEM / ODM

Our Sight Glass Level Gauge provides direct and reliable visual monitoring of liquid levels in tanks and vessels. Designed for industrial applications, it is suitable for chemical, boiler, water treatment, and general industrial systems.

As an OEM/ODM manufacturer, we offer customizable solutions to meet specific process requirements:

Material Options: Vidrio de borosilicato o cuarzo, marcos de acero inoxidable o acero al carbono, revestimientos resistentes a la corrosión.

Presión y temperatura nominales: Adjustable to match your vessel’s operating conditions.

Tipos de conexión: Flanged, threaded, or special connections for seamless integration.

Dimensions & Lengths: Tailored gauge length, chamber size, and installation orientation.

Key Features:

Direct visual liquid level observation without electricity.

Integrated safety steel ball for automatic shut-off in case of glass breakage.

Robust and low-maintenance construction for long-term reliability.

Flexible customization to suit unique industrial processes.

Applications:

Ideal for chemical tanks, boilers, water treatment systems, food and pharmaceutical vessels, and oil & gas storage, providing safe, accurate, and real-time liquid level monitoring.

Recomendaciones de productos relacionados

A glass level gauge, also called a sight glass level indicator, allows direct visual monitoring of liquid levels in tanks and vessels. It works on the communicating vessel principle, where liquid in the gauge matches the level in the connected container, providing accurate, real-time observation without electrical signals.

Industrial glass level gauges are available in transparent, reflex, and mirror-type configurations. Transparent gauges suit clear liquids, reflex types enhance visibility for steam or high-temperature media, and mirror-type gauges improve readability under low light or medium-pressure conditions.

Sight glass level indicators are widely used in chemical, petrochemical, boiler, water treatment, food, pharmaceutical, and oil & gas industries. They are ideal for medium- and low-pressure vessels requiring reliable visual monitoring of corrosive, high-temperature, or hazardous liquids.

The gauge is mounted via standard flanges or threaded connections. After pressure testing, valves should be opened gradually. Inspect periodically for leaks, and if the glass becomes contaminated, drain the medium safely before cleaning. Proper maintenance ensures stable performance and long service life.

Modern glass plate liquid level gauges include a safety steel ball. If the glass breaks or vapor/liquid side pressure exceeds 0.3 MPa, the steel ball automatically seals the flow path, preventing medium leakage. This feature ensures safe operation in chemical, boiler, and industrial environments.

Glass level gauges offer direct, accurate, and real-time liquid level observation without electricity. They are durable, corrosion-resistant, and low-maintenance, with built-in safety features. Suitable for chemical plants, boilers, water treatment, and general industrial vessels, they provide reliable, long-term performance.

Por qué elegir Instrava

Al elegir Instrava, obtiene un socio con un profundo conocimiento de las aplicaciones industriales y la experiencia necesaria para hacer frente a los retos operativos actuales.

Nuestro papel va más allá de los productos: respaldamos su éxito con soluciones fiables y un compromiso a largo plazo.

Innovación impulsada por la ingeniería

La innovación en Instrava se guía por necesidades industriales reales. Perfeccionamos continuamente nuestras tecnologías para hacer frente a los cambiantes retos operativos, garantizando un rendimiento práctico y fiable en entornos exigentes.

Personalización específica de la aplicación

Ofrecemos personalización a nivel de ingeniería para adaptarnos a las condiciones específicas del proceso. Desde el rango de medición y los materiales hasta las señales de salida y las opciones de instalación, nuestras soluciones están configuradas para adaptarse a aplicaciones reales.

Calidad y fiabilidad demostradas

La calidad y la fiabilidad son fundamentales en todos los productos Instrava. Fabricados bajo estrictos controles de calidad y sometidos a pruebas exhaustivas, nuestros instrumentos ofrecen un rendimiento preciso, estable y a largo plazo.

Capacidad global con apoyo local

Instrava combina la experiencia mundial en ingeniería con una asistencia local receptiva, lo que garantiza que nuestros socios se beneficien de una tecnología alineada internacionalmente y de un servicio regional puntual.

Amplia cartera de productos

Nuestra amplia cartera de instrumentos de medición y control nos permite dar respuesta a una amplia gama de necesidades industriales, proporcionando soluciones integradas a partir de una fuente única y fiable.

Asistencia técnica orientada a los socios

Trabajamos en estrecha colaboración con nuestros socios, desde el asesoramiento técnico hasta la asistencia posventa. Nos centramos en ofrecer soluciones que generen un valor duradero y contribuyan al éxito operativo a largo plazo.