Why Optical Dissolved Oxygen Sensors Dominate Long-Term Monitoring

Long-term dissolved oxygen monitoring is fundamentally different from short-term measurement. While many dissolved oxygen sensors can deliver acceptable accuracy at...

Transmisor

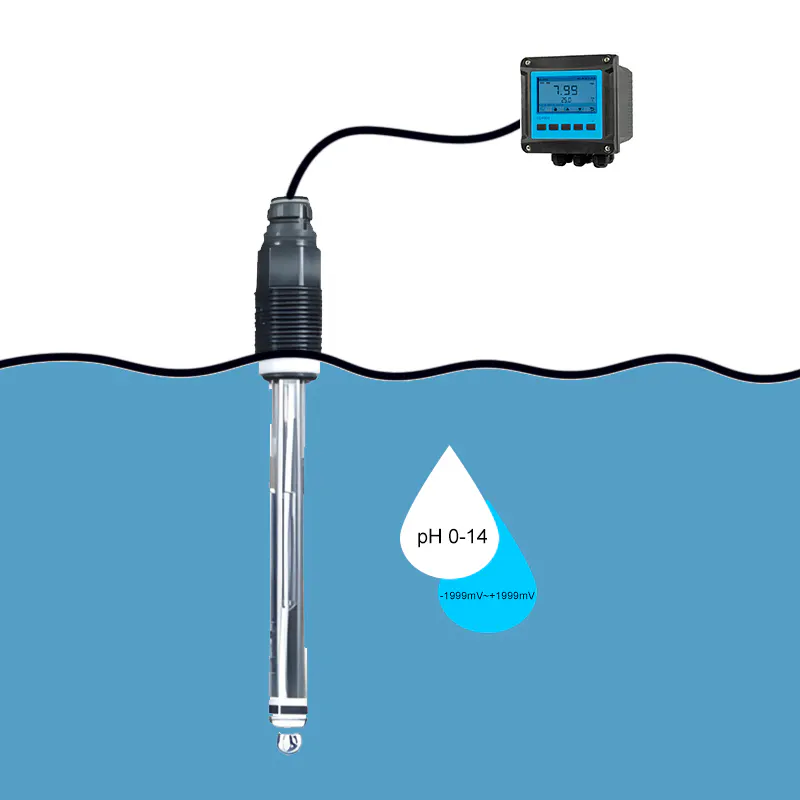

Inicio » Productos » Transmisores » Industrial Digital pH / ORP Sensor for Continuous Process Control

The Instrava pH / ORP sensor is designed for continuous, reliable measurement of acidity, alkalinity, and oxidation-reduction potential in industrial and environmental applications.

Built for long-term stability, the sensor integrates high-accuracy electrodes with digital RS485 (Modbus RTU) communication, ensuring strong anti-interference performance and seamless integration with PLC, DCS, and water quality analyzers.

It is widely used in water treatment, chemical processing, power generation, food & beverage, and environmental monitoring, where stable pH and ORP control is critical to process safety and efficiency.

Transmitters & Sensors Description

pH / ORP Sensor Key Features

High-precision pH & ORP measurement

Accurate monitoring across a wide pH and ORP range for demanding industrial processes.

Digital RS485 Modbus RTU output

Stable long-distance transmission with no signal drift, ideal for harsh electrical environments.

Industrial-grade electrode design

Fast response, strong resistance to contamination, and long service life.

Low maintenance with optional automatic cleaning

Reduces manual intervention in wastewater and chemical applications.

Wide compatibility

Fully compatible with Instrava multifunction water quality analyzers and third-party control systems.

pH/ORP Sensor Applications

Industrial water and wastewater treatment

Chemical and petrochemical processes

Power plant water systems

Environmental water monitoring

Food and beverage process water

General industrial online pH and ORP measurement

pH ORP Sensor Measurement Principle

The pH sensor measures hydrogen ion activity using a glass electrode and reference electrode.

The potential difference generated between the electrodes varies proportionally with the pH value of the solution.

ORP measurement is based on detecting the oxidation or reduction potential of the solution.

The sensor outputs a millivolt (mV) signal representing the solution’s ability to gain or lose electrons.

Both signals are digitally processed and transmitted via RS485 for stable and accurate readings.

pH ORP Sensor Installation & Integration

Immersion, pipeline, or flow-cell installation

Plug-and-play with Instrava water quality analyzers

Compatible with PLC, SCADA, and DCS systems

Suitable for continuous online monitoring

Transmitters & Sensors Parameter

| Parámetro | pH Sensor | ORP Sensor |

|---|---|---|

| Measurement Range | 0 ~ 14 pH | -1999 mV ~ +1999 mV |

| Temperatura de funcionamiento | 0 ~ 80 ℃ | -10 ~ 100 ℃ |

| Operating Pressure | ≤ 0.6 MPa | ≤ 0.8 MPa |

| Measurement Accuracy | pH: ±0.05 pH Temperature: ±0.5 ℃ | ORP: ±1 mV Temperature: ±0.5 ℃ |

| Temperature Sensor | NTC 2.252K | NTC 2.252K |

| Wetted Material | ABS, Glass | ABS, Glass |

| Protection Class | IP65 | IP65 |

| Sensor Dimensions | Ø26.7 × 160 mm Ø12 × 120 mm | Ø26.7 × 160 mm Ø12 × 120 mm |

| Conexión a proceso | 3/4″ NPT, PG13.5 | 3/4″ NPT, PG13.5 |

| Signal Cable Length | 5 m standard Up to 20 m customizable | 5 m standard Up to 20 m customizable |

Instrava OEM/ODM

Electrode material selection for specific chemical environments

Cable length and mounting accessories customization

Modbus register optimization for system integration

Calibration guidance and long-term maintenance support

Instrava focuses on stable field performance, not just laboratory accuracy.

Under normal industrial water conditions, the typical service life of a pH or ORP electrode is 12–18 months. Actual lifespan depends on water quality, temperature, chemical composition, and maintenance practices.

For stable industrial water, calibration is usually recommended once per month. In harsh or fluctuating process conditions, more frequent calibration (every 1–2 weeks) helps maintain measurement accuracy.

Electrode lifespan can be shortened by high temperature, strong acids or alkalis, oil contamination, solids abrasion, and improper cleaning. Regular inspection and correct cleaning procedures significantly extend sensor life.

Yes. The sensor is suitable for wastewater applications; however, regular cleaning is recommended to prevent fouling on the glass membrane, which may affect response time and accuracy.

The pH ORP sensor is compatible with most standard industrial pH/ORP transmitters and analyzers that support glass electrode inputs and NTC temperature compensation.

Stable long-term operation is achieved through proper installation, correct calibration, regular cleaning, and suitable electrode selection based on process conditions. Using compatible transmitters with temperature compensation further improves measurement stability.

Al elegir Instrava, obtiene un socio con un profundo conocimiento de las aplicaciones industriales y la experiencia necesaria para hacer frente a los retos operativos actuales.

Nuestro papel va más allá de los productos: respaldamos su éxito con soluciones fiables y un compromiso a largo plazo.

La innovación en Instrava se guía por necesidades industriales reales. Perfeccionamos continuamente nuestras tecnologías para hacer frente a los cambiantes retos operativos, garantizando un rendimiento práctico y fiable en entornos exigentes.

Ofrecemos personalización a nivel de ingeniería para adaptarnos a las condiciones específicas del proceso. Desde el rango de medición y los materiales hasta las señales de salida y las opciones de instalación, nuestras soluciones están configuradas para adaptarse a aplicaciones reales.

La calidad y la fiabilidad son fundamentales en todos los productos Instrava. Fabricados bajo estrictos controles de calidad y sometidos a pruebas exhaustivas, nuestros instrumentos ofrecen un rendimiento preciso, estable y a largo plazo.

Instrava combina la experiencia mundial en ingeniería con una asistencia local receptiva, lo que garantiza que nuestros socios se beneficien de una tecnología alineada internacionalmente y de un servicio regional puntual.

Nuestra amplia cartera de instrumentos de medición y control nos permite dar respuesta a una amplia gama de necesidades industriales, proporcionando soluciones integradas a partir de una fuente única y fiable.

Trabajamos en estrecha colaboración con nuestros socios, desde el asesoramiento técnico hasta la asistencia posventa. Nos centramos en ofrecer soluciones que generen un valor duradero y contribuyan al éxito operativo a largo plazo.

Long-term dissolved oxygen monitoring is fundamentally different from short-term measurement. While many dissolved oxygen sensors can deliver acceptable accuracy at...

Dissolved oxygen (DO) measurement is a critical parameter in water treatment, aquaculture, environmental monitoring, and industrial processes. Among available technologies,...

How Measurement Data Becomes a Decision Variable in Modern Industrial Systems From Field Measurement to Process Decision In traditional process...

Instrava

Director de tienda

Mejor socio

Hola, ¿en qué puedo ayudarte hoy?