Métodos de medición de la concentración de lodos

How to Select the Right Approach for Reliable Process Control Why Sludge Concentration Measurement Matters Sludge concentration is a critical...

Transmisor

Inicio » Productos » Transmisores » Suspended Solids / Sludge Concentration Sensor

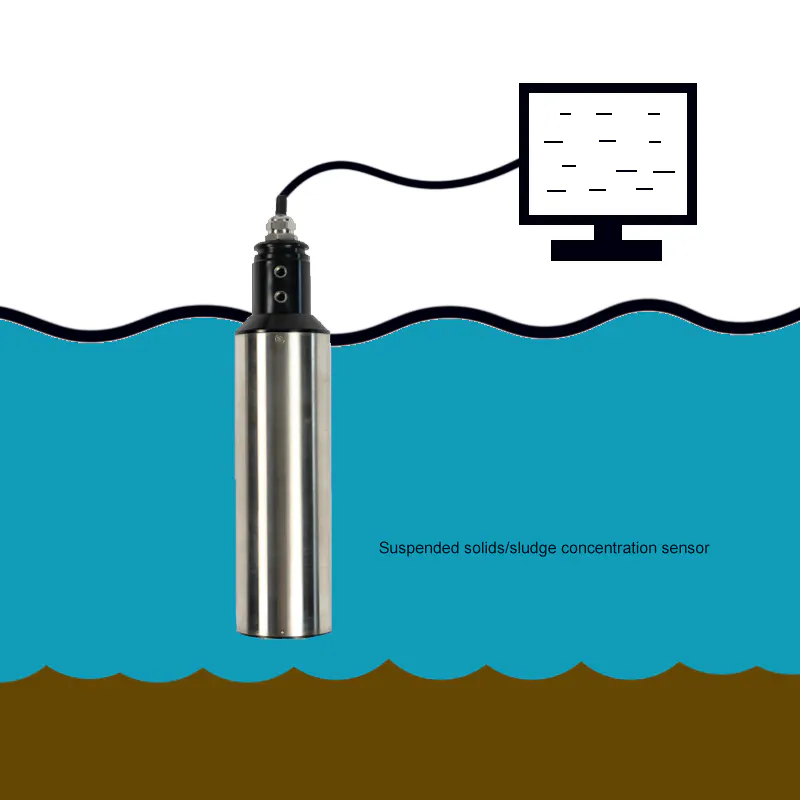

The Suspended Solids / Sludge Concentration Sensor is designed for continuous online measurement of suspended solids (SS) and sludge concentration (MLSS) in water and wastewater treatment processes.

Based on ISO 7027 infrared scattered light technology, the sensor effectively eliminates the influence of sample color and provides stable, repeatable, and reliable measurement results. It is widely used in municipal and industrial wastewater treatment plants, process water systems, and environmental monitoring applications.

Transmitters & Sensors Description

Suspended Solids Sludge Sensor Key Features & Advantages

ISO 7027 Standard Method

Uses infrared scattered light technology to minimize color interference and ensure measurement consistency.

Dual-Beam Infrared Scattering Detection

Improves accuracy, repeatability, and long-term stability.

High Measurement Reliability

Excellent repeatability and stability, suitable for continuous online monitoring.

Built-in Self-Diagnostic Function

Automatically monitors sensor status to ensure reliable and accurate data output.

Optional Automatic Cleaning Scraper

Reduces fouling and maintenance frequency, especially in high-solids applications.

RS485 Communication

Supports connection to upper-level systems such as PLC, SCADA, or data acquisition units.

Suspended Solids Sludge Sensor Typical Applications

Municipal wastewater treatment plants

Industrial wastewater treatment

Activated sludge process monitoring (MLSS)

Sedimentation tanks and aeration basins

Environmental water monitoring

Process water systems with suspended solids

Suspended Solids Sludge Sensor Measurement Principle

The sensor applies infrared scattered light photometric technology in accordance with ISO 7027. When infrared light passes through the sample, suspended solids scatter the light. The scattered light intensity is detected by a dual-beam system and converted into a concentration value, ensuring accurate measurement independent of sample color.

Suspended Solids Sludge Sensor Installation & Maintenance

The sensor is designed for submersible installation and can be directly immersed in tanks, channels, or pipelines.

For applications with high fouling potential, the optional automatic cleaning scraper is recommended to reduce maintenance workload and ensure long-term measurement stability.

Transmitters & Sensors Parameter

| Parámetro | Especificación |

|---|---|

| Measurement Range | 0.01 – 45,000 mg/L / 0.01 – 120,000 mg/L |

| Temperature Range | 0 – 45 °C |

| Pressure Range | ≤ 0.4 MPa |

| Measurement Accuracy | ±5% FS |

| Flow Velocity | ≤ 2.5 m/s |

| Señal de salida | RS485 |

| Housing Material | 316L Stainless Steel + PVC |

| Protection Class | IP68 |

| Dimensions | Ø60 × 256 mm |

| Installation Method | Submersible |

| Temperatura ambiente | 0 – 60 °C |

| Ambient Humidity | < 90% RH |

| Signal Cable | 10 m standard, customizable up to 100 m |

Instrava OEM/ODM

Instrava provides engineering-level customization and system support for suspended solids and sludge concentration measurement:

Measurement range customization for different sludge processes

Cable length extension up to 100 meters

Optional automatic wiper selection based on fouling conditions

Communication protocol configuration for PLC/DCS integration

Application-specific installation guidance and process design support

Our engineering team works closely with system integrators, OEM partners, and end users to ensure stable operation throughout the full lifecycle of the measurement system.

SS (Suspended Solids) generally refers to solids in water or effluent, while MLSS (Mixed Liquor Suspended Solids) is specific to activated sludge concentration in aeration tanks. This sensor supports both applications by measuring suspended solids using infrared scattering technology.

Accuracy can be affected by sludge particle size, air bubbles, flow turbulence, sensor fouling, and improper installation depth. Proper installation and routine cleaning significantly reduce these effects.

Maintenance frequency depends on sludge characteristics. In most wastewater plants, cleaning every 1–4 weeks is recommended. The optional automatic cleaning scraper can greatly extend maintenance intervals.

Yes. The sensor supports measurement ranges up to 120,000 mg/L, making it suitable for high-concentration sludge zones such as aeration tanks, return sludge lines, and thickening processes.

SO 7027 infrared scattered light technology minimizes the influence of sample color and ambient light, ensuring consistent and reliable sludge concentration measurement even in dark or colored wastewater.

Submersible installation in areas with stable flow and representative sludge mixing is recommended. Avoid installation near aerators, in dead zones, or areas with excessive turbulence to ensure accurate and stable readings.

Al elegir Instrava, obtiene un socio con un profundo conocimiento de las aplicaciones industriales y la experiencia necesaria para hacer frente a los retos operativos actuales.

Nuestro papel va más allá de los productos: respaldamos su éxito con soluciones fiables y un compromiso a largo plazo.

La innovación en Instrava se guía por necesidades industriales reales. Perfeccionamos continuamente nuestras tecnologías para hacer frente a los cambiantes retos operativos, garantizando un rendimiento práctico y fiable en entornos exigentes.

Ofrecemos personalización a nivel de ingeniería para adaptarnos a las condiciones específicas del proceso. Desde el rango de medición y los materiales hasta las señales de salida y las opciones de instalación, nuestras soluciones están configuradas para adaptarse a aplicaciones reales.

La calidad y la fiabilidad son fundamentales en todos los productos Instrava. Fabricados bajo estrictos controles de calidad y sometidos a pruebas exhaustivas, nuestros instrumentos ofrecen un rendimiento preciso, estable y a largo plazo.

Instrava combina la experiencia mundial en ingeniería con una asistencia local receptiva, lo que garantiza que nuestros socios se beneficien de una tecnología alineada internacionalmente y de un servicio regional puntual.

Nuestra amplia cartera de instrumentos de medición y control nos permite dar respuesta a una amplia gama de necesidades industriales, proporcionando soluciones integradas a partir de una fuente única y fiable.

Trabajamos en estrecha colaboración con nuestros socios, desde el asesoramiento técnico hasta la asistencia posventa. Nos centramos en ofrecer soluciones que generen un valor duradero y contribuyan al éxito operativo a largo plazo.

How to Select the Right Approach for Reliable Process Control Why Sludge Concentration Measurement Matters Sludge concentration is a critical...

Long-term dissolved oxygen monitoring is fundamentally different from short-term measurement. While many dissolved oxygen sensors can deliver acceptable accuracy at...

Dissolved oxygen (DO) measurement is a critical parameter in water treatment, aquaculture, environmental monitoring, and industrial processes. Among available technologies,...

Instrava

Director de tienda

Mejor socio

Hola, ¿en qué puedo ayudarte hoy?