Débitmètre

Accueil » Produits » Débitmètre » Débitmètre à ultrasons à pince

Débitmètre à ultrasons à pince

High-Precision Industrial Measurement

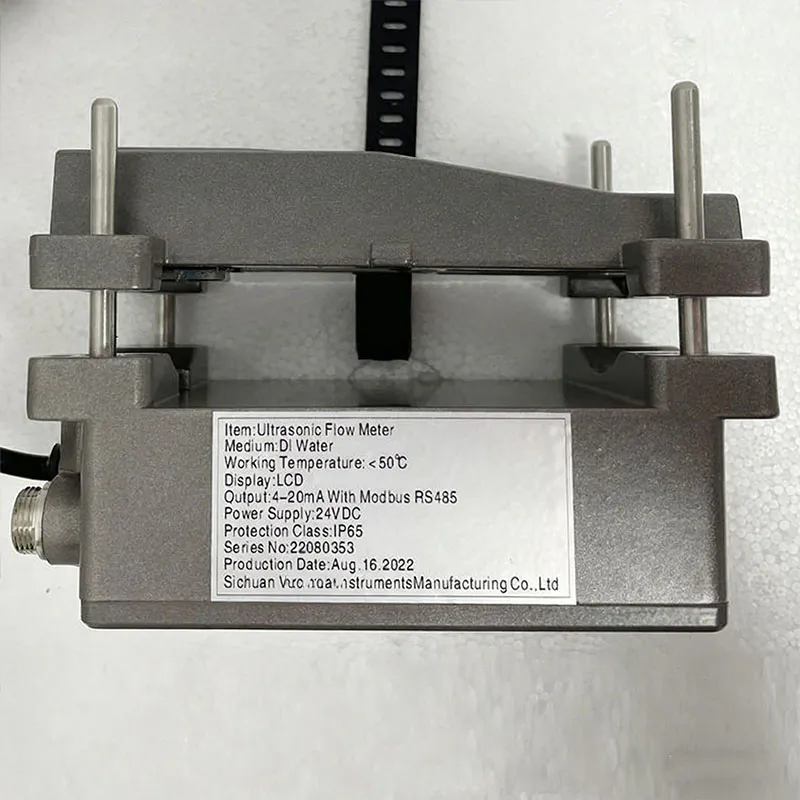

The Clamp-On Ultrasonic Flow Meter delivers accurate transit-time flow measurement for industrial liquids. Using a 700,000-gate industrial FPGA chip and proprietary TGA technology, it improves signal sampling and bubble tolerance, ensuring fast and precise measurements even with transient bubbles or impurities.

Non-Invasive Installation & Easy Operation

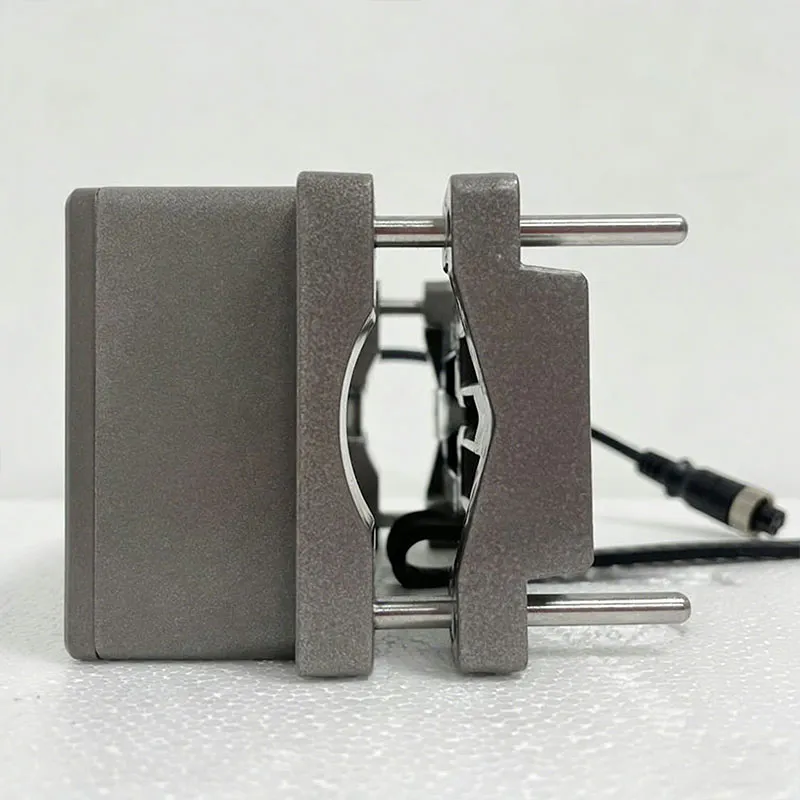

The clamp-on design allows external installation on pipes without cutting or stopping the system, preventing pressure loss and avoiding fluid contamination. Quick and simple setup saves labor and downtime, making it ideal for continuous operation in industrial environments.

Versatile Applications & Customization

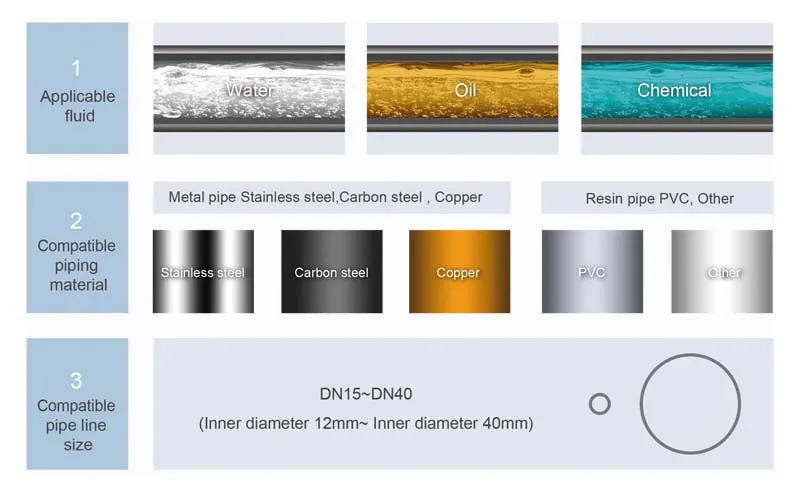

Suitable for water, chemical, HVAC, food & beverage, pharmaceutical, and energy monitoring applications, it supports metal and plastic pipes (PVC, PP, PVDF) and a wide range of pipe sizes. OEM/ODM options include sensor size, flow range, output signals (4–20 mA, pulse, Modbus), and optional energy measurement (BTU/heat/cooling).

Durable Industrial Design & Data Management

Built with aluminum and industrial-grade plastics and rated IP65, the flow meter withstands vibration, impact, and harsh environments. EEPROM memory stores data for over 10 years, and the high-resolution LCD display provides real-time flow, total volume, and energy readings for reliable monitoring and process control.

Flow Meter Description

Clamp On Ultrasonic Flow Meter-Features

User-friendly clamp-on design enables quick installation and operation, taking only a few minutes from setup to measurement.

Non-invasive external clamp design measures flow without contacting the medium, preventing pressure loss or contamination compared with traditional flow meters.

No need to cut pipes or stop system operation, saving time, labor, and operational costs—ideal for continuous industrial processes.

Flexible configuration with multiple modes; one sensor fits all pipe sizes within the measuring range, compatible with metal and plastic pipes.

High-resolution 256×128 LCD display shows flow rate, total volume, and other key parameters.

Optional upgrade to an ultrasonic energy meter, BTU meter, or heat/cooling meter for comprehensive energy monitoring and management.

Ultrasonic Flowmeter Clamp On-Applications

Water treatment and distribution monitoring for industrial and municipal systems.

Chemical, petrochemical, and pharmaceutical process flow measurement.

HVAC systems for energy efficiency and heat/cooling monitoring.

Food and beverage production lines requiring non-invasive flow measurement.

Wastewater monitoring and environmental management.

Industrial energy monitoring when configured as ultrasonic energy or BTU meter.

Ultrasonic Flow Meter Clamp On-Measuring Principle

The clamp-on ultrasonic flow meter uses the transit-time ultrasonic principle: ultrasonic pulses are sent across the pipe in both directions. The time difference between upstream and downstream pulses is measured, allowing precise calculation of the flow rate. Non-invasive clamp-on installation ensures zero pressure drop and no contamination of the measured fluid. Proprietary TGA technology improves signal processing, tolerates transient bubbles, and ensures highly accurate, stable measurements even in challenging flow conditions.

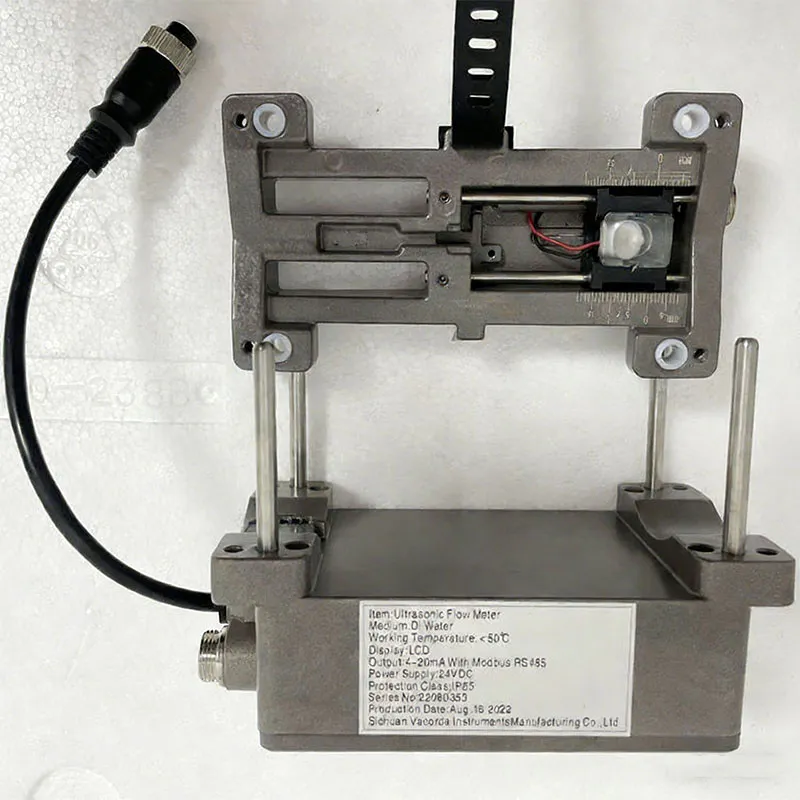

Clamp-On Ultrasonic Flow Meter-Structure

Clamp-On Sensor: External installation on the pipe, non-invasive and suitable for retrofitting existing pipelines.

Integrated or Split Transmitter: Compact transmitter with display or remote unit for flexible installation.

Universal Sensor Design: One sensor can cover a wide range of pipe diameters and materials (metal or resin).

Optional Display and Output Modules: LCD/LED display, 4–20 mA, pulse, or Modbus outputs.

Rugged Housing: Suitable for industrial environments, optional explosion-proof or waterproof models.

Flow Meter Parameter

| Paramètres | Spécifications |

|---|---|

| Pipe Material | Metal / PVC / PP / PVDF rigid plastic pipes |

| Liquid Type | Water or other single-phase liquids without solid particles or impurities |

| Temperature Range | 0–75°C (no surface freezing) |

| Low Velocity Cut-Off | 0.1 m/s (default by factory) |

| Display | 256×128 LCD |

| Response Time | 0.5–60 s |

| Précision | ±2% (±1% after calibration) |

| Data Storage Period | 300 ms |

| Memory for Data Backup | EEPROM (over 10 years, read/write frequency > 1 million times) |

| Power & I/O Connection | M12 aviation plug |

| Output | 4-20 mA |

| Communication | Modbus RS485 |

| Optional Output | OCT (pulse output) / One relay alarm (contact factory) |

| Alimentation électrique | 10–24 VDC |

| Electric Power | < 3 W |

| Protective Circuit | Output short-circuit and surge protection |

| Enclosure Protection Class | IP65 |

| Environmental Temperature | -10 to 60°C (no freezing) |

| Humidité relative | 35–85% RH (no condensation) |

| Vibration Resistance | Double amplitude 1.5 mm, 2 hours per XYZ axis |

| Impact Resistance | 100 m/s², 16 ms pulse, 1000 times per XYZ axis |

| Main Material | Aluminum, industrial plastics |

| Cable Length | 2 m standard (PT1000 sensor cable 9 m standard) |

Flow Range

| Pipe Size (DN) | Upper Flow Value (L/min) |

|---|---|

| 15 | 60 |

| 20 | 100 |

| 25 | 200 |

| 32 | 300 |

| 40 | 400 |

Flow Meter OEM/ODM

Clamp-On Ultrasonic Flow Meter – OEM / ODM Customization

Our clamp-on ultrasonic flow meters are designed for industrial-grade, high-precision flow measurement with non-invasive installation. We provide flexible OEM and ODM solutions to meet diverse industrial requirements.

Customizable Options Include:

Sensor & Pipe Compatibility: Custom sizes for metal, PVC, PP, PVDF, and other rigid pipes.

Measurement Range & Accuracy: Tailored calibration for specific flow rates and ±1% high-precision accuracy.

Display & Output: Optional LCD/LED displays, 4–20 mA, pulse output, Modbus RS485, or energy measurement functionality (BTU/heat/cooling).

Housing & Protection: Explosion-proof, waterproof, and rugged housings for industrial environments.

Branding & Packaging: Custom labeling, logos, and packaging for OEM clients.

Integration: Compatible with SCADA, PLC, and other industrial control systems for seamless installation.

Why Choose Our OEM/ODM Clamp-On Ultrasonic Flow Meters:

Quick, non-invasive installation without cutting pipes or stopping flow.

Handles complex flow conditions, including transient bubbles and impurities.

Durable, long-lasting, and low-maintenance design suitable for continuous operation.

Flexible customization to fit unique industrial processes and energy monitoring applications.

Applications for OEM/ODM Solutions:

Water treatment, chemical processing, pharmaceutical production, HVAC systems, energy monitoring, food & beverage lines, and wastewater management.

Recommandations de produits connexes

A clamp-on ultrasonic flow meter is a non-invasive flow measurement device that uses transit-time ultrasonic technology. It clamps externally on pipes, measuring flow without contacting the liquid. This prevents pressure loss, avoids contamination, and allows installation without stopping industrial pipelines. Ideal for water, chemical, HVAC, food & beverage, and pharmaceutical applications.

Our industrial clamp-on ultrasonic flow meters deliver ±2% accuracy by default and ±1% after calibration. With proprietary TGA signal processing, the meters handle transient bubbles and impurities in the liquid, ensuring reliable flow measurement even under complex industrial conditions. Measurement range: 0.1 m/s to 10 m/s; pipe sizes DN15–DN3000 mm.

Yes, we provide full OEM/ODM customization, including:

– Sensor size and pipe compatibility (Metal, PVC, PP, PVDF)

– Flow range and calibration

– Output signals (4–20 mA, pulse, Modbus RS485)

– Display type (LCD/LED)

– Housing protection (IP65, explosion-proof)

– Branding and packaging customization. This ensures meters meet specific industrial or energy-monitoring requirements.

Installation is extremely quick and non-invasive. The clamp-on sensor attaches externally to the pipe in minutes, requiring no pipe cutting or system shutdown. This reduces labor costs, minimizes downtime, and supports continuous operations in industrial plants. Optional split/transmitter designs allow flexible installation in tight spaces.

Yes, the meter can be upgraded to an ultrasonic energy meter, BTU meter, or heat/cooling meter. It measures flow and calculates energy consumption, suitable for HVAC systems, district heating, and industrial energy monitoring. Supports output via 4–20 mA, pulse, or Modbus RS485, integrating seamlessly with SCADA or PLC systems.

– Non-invasive measurement prevents contamination and pressure loss

– Quick, easy installation with no downtime

– High precision (±1% after calibration)

– Wide compatibility: pipe sizes DN15–DN3000 mm, metal/plastic pipes

– Robust industrial design: IP65, vibration/impact resistant

– OEM/ODM customizable for industrial or energy applications.

This combination makes it ideal for industrial and municipal water, chemical, HVAC, and energy management applications.

Pourquoi choisir Instrava ?

En choisissant Instrava, vous bénéficiez d'un partenaire ayant une connaissance approfondie des applications industrielles et l'expertise nécessaire pour relever les défis opérationnels d'aujourd'hui.

Notre rôle va au-delà des produits - nous soutenons votre réussite grâce à des solutions fiables et à un engagement à long terme.

L'innovation par l'ingénierie

L'innovation chez Instrava est guidée par les exigences industrielles réelles. Nous affinons continuellement nos technologies pour répondre aux défis opérationnels en constante évolution, en garantissant des performances pratiques et fiables dans des environnements exigeants.

Personnalisation en fonction de l'application

Nous offrons une personnalisation au niveau de l'ingénierie pour répondre aux conditions spécifiques du processus. De la plage de mesure et des matériaux aux signaux de sortie et aux options d'installation, nos solutions sont configurées pour s'adapter aux applications réelles.

Une qualité et une fiabilité éprouvées

La qualité et la fiabilité sont fondamentales pour chaque produit Instrava. Fabriqués sous un contrôle de qualité strict et testés de manière approfondie, nos instruments offrent des performances précises, stables et à long terme.

Une capacité mondiale avec un soutien local

Instrava associe une expertise technique mondiale à un support local réactif, garantissant à nos partenaires une technologie alignée au niveau international et un service régional opportun.

Un portefeuille de produits complet

Notre large gamme d'instruments de mesure et de contrôle nous permet de répondre à un grand nombre de besoins industriels, en fournissant des solutions intégrées à partir d'une source unique et fiable.

Soutien technique axé sur les partenaires

Nous travaillons en étroite collaboration avec nos partenaires, de la consultation technique à l'assistance après-vente. Notre objectif est de fournir des solutions qui créent une valeur durable et soutiennent le succès opérationnel à long terme.