Расходомер

Главная » Продукция » Расходомер » Расходомер с отверстиями

Расходомер с отверстиями

In petroleum, chemical, metallurgy, electric power, textile, and military manufacturing industries, throttling devices are widely used for fluid flow measurement and process control. Among them, the orifice flow meter remains one of the most mature and commonly adopted differential pressure flow measurement solutions.

Standard orifice plate flow meters operate based on well-established international measurement principles, providing stable performance for liquid, gas, and steam flow measurement under various operating conditions.

Standard-Compliant Throttling Devices

Our company manufactures a full range of throttling devices strictly in accordance with international standard ISO 5167:2003 and national standard GB/T 2624-2006. These standards ensure the accuracy, repeatability, and interchangeability of each orifice plate flow meter supplied.

Standard products include concentric orifice plates designed for differential pressure flow measurement in high-pressure, high-temperature, and continuous industrial processes.

Flow Meter Description

Orifice Flow Meter-Features

The throttling device features a simple and standardized structure, ensuring stable, reliable performance and a long service life under continuous industrial operation.

Orifice plate flow meter design and bore calculation are carried out strictly according to international standards, allowing the device to be installed and commissioned without on-site flow calibration.

The orifice flow meter offers wide applicability and is suitable for measuring single-phase fluids such as liquids, gases, and steam, as well as certain mixed-phase flow conditions.

The measuring range is wide, with a turndown ratio exceeding 10:1, enabling stable flow measurement across varying process loads.

Installation is simple and flexible. The orifice plate flow meter can be directly connected to a differential pressure transmitter or pressure transmitter, eliminating the need for long impulse lines.

Multiple communication interfaces are available, supporting common industrial protocols for easy integration into DCS and PLC control systems.

The intelligent orifice plate flow meter supports self-diagnosis functions and flexible range configuration, improving operational reliability and reducing maintenance requirements.

Orifice Plate Flow Meter Applications

The orifice flow meter is widely used for steam, natural gas, and high-pressure pipeline flow measurement in industrial process systems.

For steam applications, the orifice plate flow meter provides stable and repeatable measurement for saturated and superheated steam in boilers, power plants, and thermal energy systems, supporting mass flow calculation with temperature and pressure compensation.

In natural gas pipelines, the orifice flow meter is commonly applied in transmission lines, metering stations, and industrial fuel gas systems, offering standardized differential pressure flow measurement in accordance with ISO 5167.

For high-pressure liquid and gas pipelines, the orifice plate flow meter features a robust structure with no moving parts, making it suitable for long-term operation in petrochemical, chemical, and energy industries.

Orifice Plate Flowmeter Measuring Principle

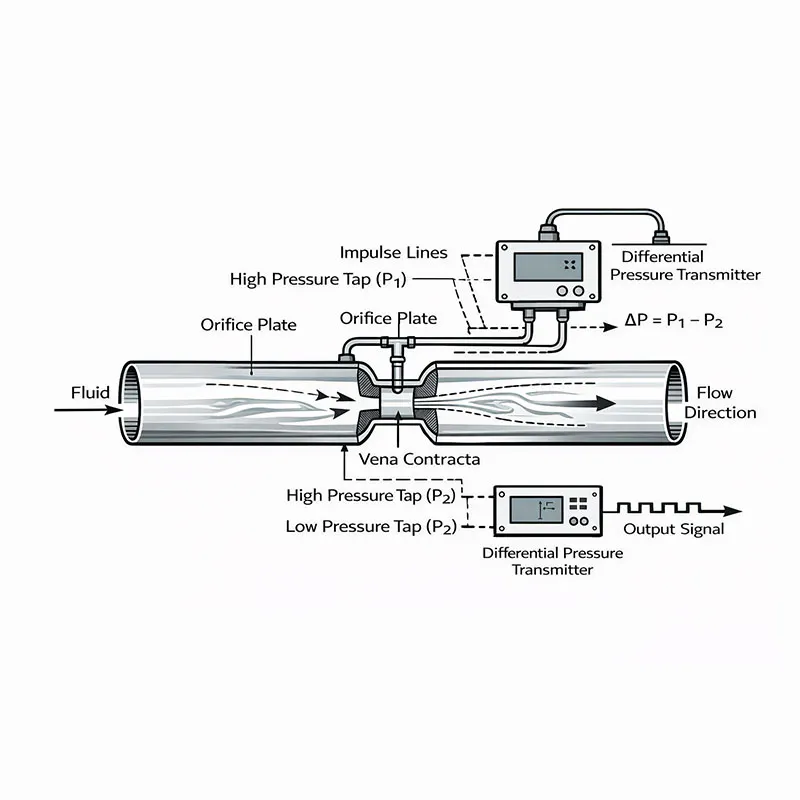

The LG throttling device is the primary element of a differential pressure flow measurement system. It consists of an orifice plate (throttling element), pressure tapping device, and the required upstream and downstream straight pipe sections.

Throttling devices are classified into standard and non-standard types. Orifice flow meters that comply with ISO 5167 and GB/T 2624 standards are defined as standard throttling devices, while other specially designed throttling elements are considered non-standard throttling devices.

When a fluid fully fills the pipeline and flows through the orifice plate, a local constriction is formed at the throttling element. According to the principles of energy conservation and flow continuity, the fluid velocity increases at the orifice, while the static pressure decreases. As a result, a differential pressure is generated between the upstream and downstream sides of the orifice plate.

The magnitude of the differential pressure is directly related to the flow velocity and flow rate of the fluid. By measuring the differential pressure across the orifice plate using a differential pressure transmitter, the volumetric or mass flow rate can be accurately calculated.

In practical applications, standard orifice flow meters are generally recommended due to their well-defined coefficients and high measurement reliability. Non-standard throttling devices may be selected when the Reynolds number is low or when the fluid contains impurities or special flow characteristics.

Orifice Flow Meter Product Structure

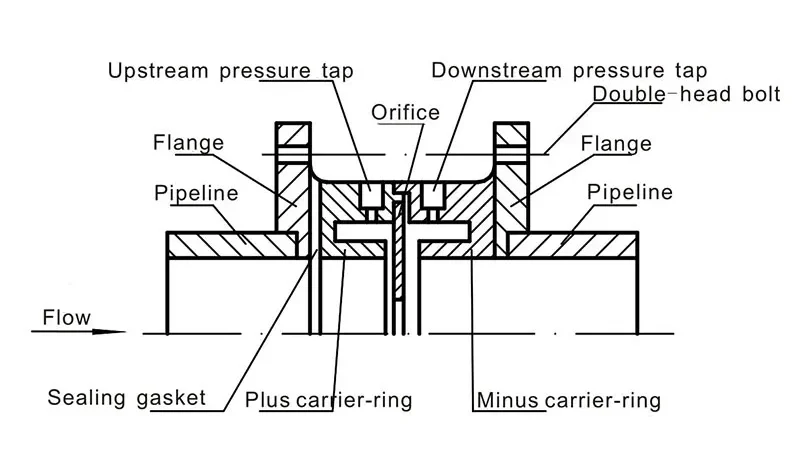

A standard orifice flow meter system consists of the following components:

• Orifice plate with precise bore diameter

• Orifice plate holder or flange tapping structure

• Upstream and downstream pressure tapping ports

• Differential pressure transmitter

• Impulse lines and mounting accessories

Different tapping types such as corner taps, flange taps, or D-D/2 taps can be selected based on application standards and pipeline conditions.

Flow Meter Parameter

| Параметр | Технические характеристики |

|---|---|

| Nominal diameter | DN10 – DN1200 |

| Measuring accuracy | ±0.5%, ±1.0%, ±1.5% |

| Flow range (turndown ratio) | ≥ 1:15 |

| Nominal pressure | 0.6 MPa, 1.0 MPa, 1.6 MPa, 2.5 MPa, 4.0 MPa, 6.4 MPa, 10 MPa |

| Measured medium | Saturated steam, superheated steam, water, air, natural gas, other mixed media |

| Medium temperature | -10°C to +450°C |

| Электропитание | Intelligent flow totalizer: 220 VAC; Flow transmitter: 24 VDC (powered by the totalizer) |

| Выходной сигнал | 4–20 mA DC or RS485 communication |

| Explosion-proof rating | Intrinsically safe Ex ib IIC T5 |

Flow Meter OEM/ODM

OEM / ODM Настройка

As a professional orifice flow meter manufacturer, we provide full OEM and ODM customization services to meet different project requirements:

• Custom orifice plate materials for corrosive or high-temperature media

• Bore calculation and flow range optimization based on process data

• Special flange standards and pressure ratings

• Integration with selected differential pressure transmitters

• Private labeling, documentation, and packaging customization

Our factory supports small-batch prototyping and large-scale production, ensuring consistent quality and delivery for global industrial projects.

Рекомендации по сопутствующим товарам

The orifice flow meter is one of the most widely used differential pressure flow meters due to its standardized design and long-term stability. Compared with turbine, vortex, or ultrasonic flow meters, the orifice plate flow meter offers superior performance in high-temperature, high-pressure, and large-diameter pipeline applications.

Its simple structure with no moving parts ensures high reliability and minimal maintenance requirements. In addition, orifice flow meters comply with international standards such as ISO 5167, making them suitable for standardized projects and long-term industrial operation.

Yes, the orifice plate flow meter is particularly suitable for saturated steam and superheated steam flow measurement. It is widely applied in boilers, power plants, and thermal energy systems.

When combined with pressure and temperature compensation, the orifice flow meter can accurately calculate steam mass flow. This makes it ideal for energy management, steam distribution monitoring, and process control in high-temperature environments.

| Steam type | Application advantage |

|---|---|

| Saturated steam | Stable measurement under constant pressure and temperature |

| Superheated steam | Accurate mass flow calculation with compensation |

| High-pressure steam | Strong mechanical strength and pressure resistance |

The orifice flow meter is one of the most recognized solutions for natural gas flow measurement, especially in transmission pipelines and industrial gas systems. Its measurement principle is well-defined and traceable, making it suitable for process monitoring and custody transfer applications.

With proper straight pipe length and installation in accordance with ISO 5167, the orifice plate flow meter provides stable and repeatable flow measurement across a wide operating range.

Standard throttling devices refer to orifice flow meters designed and manufactured according to ISO 5167 or GB/T 2624. These devices have fixed calculation formulas and coefficients, ensuring consistent measurement accuracy.

Non-standard throttling devices are used when process conditions deviate from standard requirements, such as low Reynolds numbers, limited straight pipe lengths, or fluids containing impurities.

| Тип | Typical use case |

|---|---|

| Standard orifice plate | Clean fluids, stable flow, standardized pipelines |

| Segmental orifice plate | Fluids with impurities or solids |

| Double orifice plate | Low Reynolds number applications |

| Conical entrance orifice | Short straight pipe conditions |

In most cases, an orifice flow meter does not require on-site flow calibration. The orifice plate bore is calculated and manufactured according to international standards, allowing the device to be installed and commissioned directly.

However, correct installation, proper straight pipe lengths, and accurate pressure and temperature measurement are critical factors affecting overall system accuracy. For custody transfer or high-accuracy applications, system verification may be recommended.

Yes, orifice flow meters can be fully customized to meet specific operating conditions. As an OEM / ODM orifice flow meter manufacturer, throttling devices can be designed based on customer drawings or process data.

Customization options include special materials, high-pressure flange ratings, special tapping configurations, and integration with intelligent differential pressure transmitters. This ensures the orifice plate flow meter performs reliably even in harsh industrial environments.

Почему стоит выбрать Instrava

Выбирая компанию Instrava, вы получаете партнера с глубоким пониманием промышленных применений и опытом, позволяющим решать современные производственные задачи.

Наша роль выходит за рамки продукции - мы поддерживаем ваш успех с помощью надежных решений и долгосрочных обязательств.

Инновации, управляемые инженерами

Инновации компании Instrava основаны на реальных промышленных требованиях. Мы постоянно совершенствуем наши технологии для решения возникающих производственных задач, обеспечивая практичную и надежную работу в сложных условиях.

Настройка под конкретное приложение

Мы обеспечиваем настройку на инженерном уровне для соответствия конкретным условиям процесса. От диапазона измерений и материалов до выходных сигналов и вариантов установки - наши решения настраиваются в соответствии с реальными условиями применения.

Проверенное качество и надежность

Качество и надежность являются основой каждого продукта Instrava. Изготовленные под строгим контролем качества и тщательно протестированные, наши приборы обеспечивают точную, стабильную и долговременную работу.

Глобальный потенциал с поддержкой на местах

Компания Instrava сочетает глобальный инженерный опыт с оперативной поддержкой на местах, обеспечивая нашим партнерам преимущества международных технологий и своевременного регионального обслуживания.

Широкий ассортимент продукции

Широкий ассортимент измерительных и контрольно-измерительных приборов позволяет нам удовлетворять широкий спектр промышленных потребностей, предлагая комплексные решения из одного надежного источника.

Инженерная поддержка, ориентированная на партнеров

Мы тесно сотрудничаем с нашими партнерами, начиная с технических консультаций и заканчивая послепродажным обслуживанием. Наше внимание сосредоточено на предоставлении решений, которые создают долгосрочную ценность и поддерживают долгосрочный операционный успех.