Level Measuring Instruments

Home » Products » Level Measuring Instruments » Glass Level Gauge / Sight Glass Level Indicator

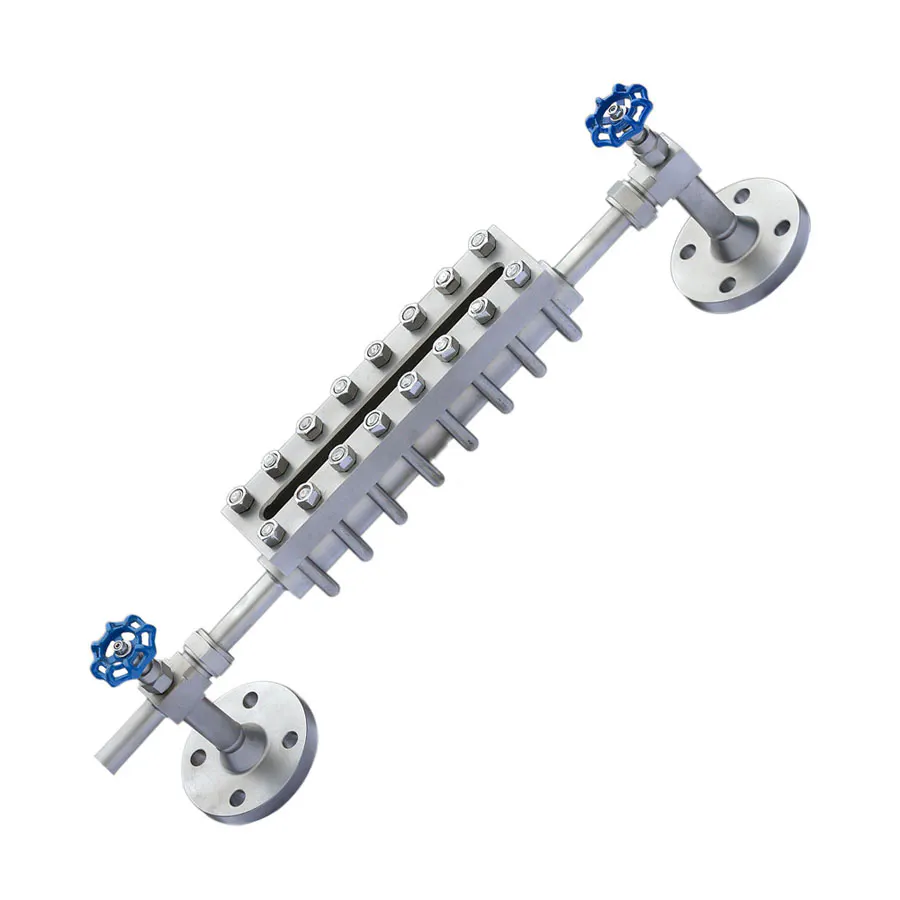

Glass Level Gauge / Sight Glass Level Indicator

The Glass Level Gauge is a direct-reading liquid level measuring instrument designed for continuous visual monitoring of liquid levels in tanks, vessels, and pipelines. By utilizing a transparent glass tube or flat glass panel, operators can clearly observe the actual liquid level in real time, ensuring safe and reliable process control.

✔ Direct visual indication

✔ Simple structure, no power required

✔ Suitable for harsh industrial environments

Level Measuring Instruments Description

Glass Level Gauge-Product Features

1️⃣ Direct Visual Liquid Level Indication

The glass level gauge provides a true, real-time visual indication of the actual liquid level inside tanks and vessels. Unlike electronic sensors, it displays the liquid position directly through the sight glass, allowing operators to immediately identify level changes, foaming, or abnormal conditions.

2️⃣ Integrated Quick Shut-Off Safety Device

Designed with a built-in quick shut-off mechanism, the gauge automatically isolates the process in the event of glass breakage or leakage. This safety feature effectively prevents vapor or liquid escape, enhancing operator safety and minimizing process risks.

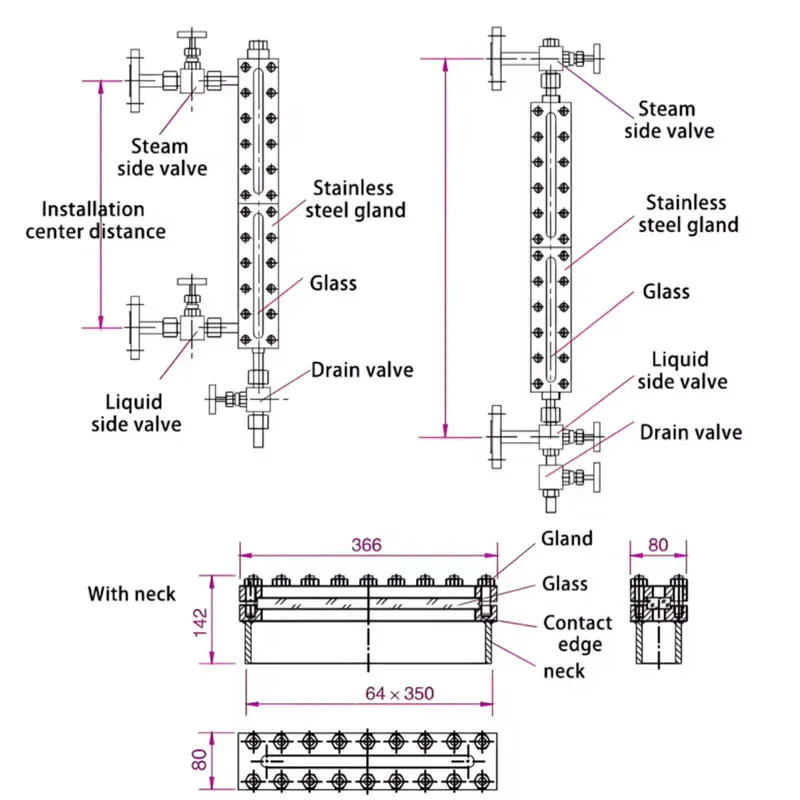

3️⃣ Robust & Practical Structural Design

The sight glass level gauge features a compact and well-engineered structure, ensuring easy installation on existing tanks or pipelines. Standard process connections allow for fast commissioning, while the modular design simplifies routine inspection and part replacement.

4️⃣ Low Maintenance & Cost-Effective Operation

With no power supply or signal components required, the glass level gauge offers long-term stable operation with minimal maintenance. The durable glass and metal components reduce downtime and spare part costs, making it an economical solution for continuous level monitoring.

Sight Glass Level Gauge-Applications / Industries

The glass plate liquid level gauge is widely used in various industrial systems where reliable and direct liquid level monitoring is required. Typical applications include:

Chemical & Petrochemical Plants

Ideal for corrosive or hazardous liquids. Provides real-time visual monitoring of reaction tanks, storage vessels, and process systems.Boilers & Steam Systems

Ensures accurate water level observation in boiler drums and steam vessels. High-temperature and pressure-resistant design with integrated safety protection.Water Treatment Systems

Enables continuous monitoring of water levels in filtration, storage, and circulation systems. Simple structure allows easy installation and maintenance.Food & Pharmaceutical Processing

Supports observation of liquid levels in clean and sanitary environments. Compatible with hygienic media and easy to sanitize.Oil & Gas Storage and Transportation

Provides safe and reliable monitoring for oil tanks, fuel storage, and pipelines. Robust design ensures stable operation under varying pressures and temperatures.

Glass Sight Glass Level Gauge-Working Principle

In general industrial systems such as water treatment units, oil tanks, and auxiliary process vessels, the glass plate liquid level gauge provides a simple and reliable method for liquid level observation. Once installed on the tank, the gauge chamber and vessel form a communicating structure, ensuring consistent liquid level indication.

The liquid level can be directly observed through the glass plate without external power supply or signal processing. The mechanical design allows stable operation under continuous service conditions, making it suitable for routine level monitoring across a wide range of industrial processes.

Installed on chemical tanks or reactors, the glass plate liquid level gauge forms a communicating vessel with the process system, enabling direct visual level observation. In case of glass rupture, the built-in safety steel ball automatically seals the flow path to reduce hazardous media leakage.

Connected to the steam and water spaces of the boiler drum, the gauge directly displays the actual boiler water level in real time. If the glass plate breaks, the automatic shut-off mechanism immediately isolates steam and water flow to ensure safe operation.

Level Gauge Sight Glass-Structure Comparison

| Type | Structural Characteristics | Visual Effect | Typical Applications |

|---|---|---|---|

| Transparent Type | Double transparent glass plates with sealed chamber; simple mechanical structure | Direct and clear observation of actual liquid level and medium | Water, oil, non-toxic liquids, general industrial tanks |

| Reflex Type | Prismatic glass surface with reflective structure; light reflection enhances contrast | Liquid appears dark, vapor area appears bright | Steam systems, boilers, high-temperature liquids |

| Mirror-Type | Flat glass with internal mirror-assisted visual enhancement | Improved readability under limited lighting conditions | Medium-pressure vessels, indoor or low-light environments |

Level Measuring Instruments Parameter

| Custom | Support OEM/ODM |

| Medium | liquid or material that is generally or slightly corroded |

| Measuring Range | 5m, 10m, 15m, 30m, 50m, 60m,120m |

| Transducer Material | Ceramic |

| Measurement Error | 0.5%. 1.0% |

| Accuracy | ±3mm (no wave calm water surface) |

| Resolution | 3~5mm or 0.1% (take large value) |

| Display Mode | LCD, parameters can be set through the panel buttons |

| Signal Output | 4~20mADC |

| Relay Output | 2 groups are optional, and the relay status is programmable |

| Working Temperature | -25~80 ℃ |

| Communication Interface | RS232, RS485/Modbus |

| Electrical Interface | M20*1.5, 1/2″PT |

| Explosion-proof Grade | ExiaIICT6Ga/ExdIICT6Gb |

| Protection level: | IP67 |

| Shell material: | engineering-plastics, aluminum alloy, SS304 |

| Ambient temperature: | (meter) -20-60 ℃; (sensor) -20~80 ℃ |

| Relative Humidity | 95% |

Level Measuring Instruments OEM/ODM

Sight Glass Level Gauge – OEM / ODM

Our Sight Glass Level Gauge provides direct and reliable visual monitoring of liquid levels in tanks and vessels. Designed for industrial applications, it is suitable for chemical, boiler, water treatment, and general industrial systems.

As an OEM/ODM manufacturer, we offer customizable solutions to meet specific process requirements:

Material Options: Borosilicate or quartz glass, stainless steel or carbon steel frames, corrosion-resistant coatings.

Pressure & Temperature Ratings: Adjustable to match your vessel’s operating conditions.

Connection Types: Flanged, threaded, or special connections for seamless integration.

Dimensions & Lengths: Tailored gauge length, chamber size, and installation orientation.

Key Features:

Direct visual liquid level observation without electricity.

Integrated safety steel ball for automatic shut-off in case of glass breakage.

Robust and low-maintenance construction for long-term reliability.

Flexible customization to suit unique industrial processes.

Applications:

Ideal for chemical tanks, boilers, water treatment systems, food and pharmaceutical vessels, and oil & gas storage, providing safe, accurate, and real-time liquid level monitoring.

A glass level gauge, also called a sight glass level indicator, allows direct visual monitoring of liquid levels in tanks and vessels. It works on the communicating vessel principle, where liquid in the gauge matches the level in the connected container, providing accurate, real-time observation without electrical signals.

Industrial glass level gauges are available in transparent, reflex, and mirror-type configurations. Transparent gauges suit clear liquids, reflex types enhance visibility for steam or high-temperature media, and mirror-type gauges improve readability under low light or medium-pressure conditions.

Sight glass level indicators are widely used in chemical, petrochemical, boiler, water treatment, food, pharmaceutical, and oil & gas industries. They are ideal for medium- and low-pressure vessels requiring reliable visual monitoring of corrosive, high-temperature, or hazardous liquids.

The gauge is mounted via standard flanges or threaded connections. After pressure testing, valves should be opened gradually. Inspect periodically for leaks, and if the glass becomes contaminated, drain the medium safely before cleaning. Proper maintenance ensures stable performance and long service life.

Modern glass plate liquid level gauges include a safety steel ball. If the glass breaks or vapor/liquid side pressure exceeds 0.3 MPa, the steel ball automatically seals the flow path, preventing medium leakage. This feature ensures safe operation in chemical, boiler, and industrial environments.

Glass level gauges offer direct, accurate, and real-time liquid level observation without electricity. They are durable, corrosion-resistant, and low-maintenance, with built-in safety features. Suitable for chemical plants, boilers, water treatment, and general industrial vessels, they provide reliable, long-term performance.

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.