Sludge Concentration Measurement Methods

How to Select the Right Approach for Reliable Process Control Why Sludge Concentration Measurement Matters Sludge concentration is a critical...

Transmisor

Inicio » Productos » Transmisores » Multi-Parameter Water Quality Sensor

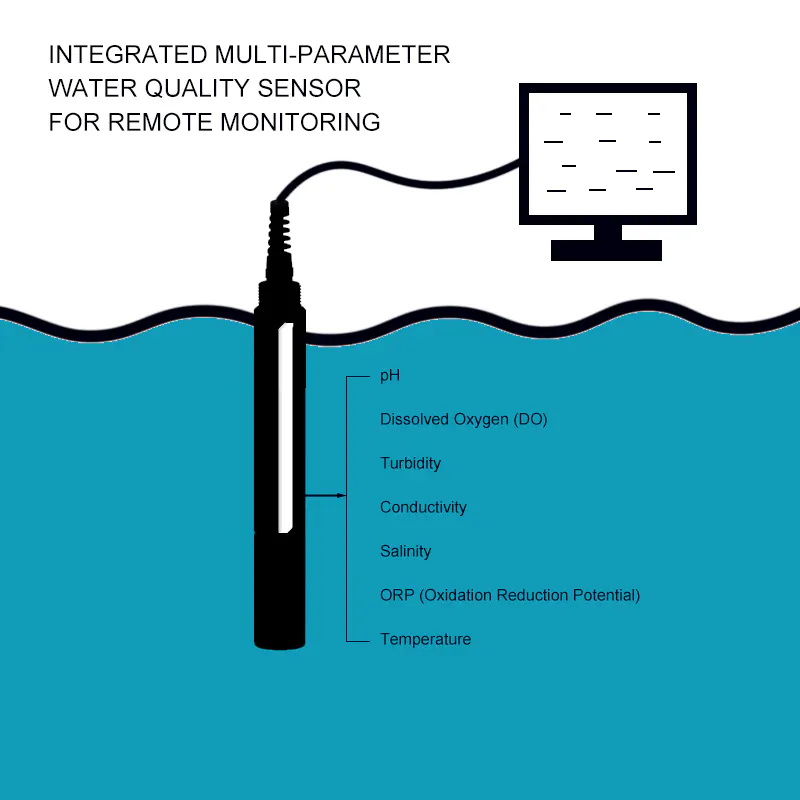

The multi-parameter water quality sensor is designed to work seamlessly with Instrava multifunction water quality analyzers.

A single integrated probe enables simultaneous measurement of up to seven key water quality parameters, significantly reducing installation space, wiring complexity, and maintenance workload.

With digital RS-485 (Modbus RTU) output, automatic cleaning capability, and wide power supply compatibility, the sensor is ideal for continuous online monitoring in water treatment, chemical processes, environmental monitoring, and industrial wastewater applications.

Transmitters & Sensors Description

7-in-1 Digital Sensor-Measured Parameters

This integrated sensor supports the following parameters within one compact structure:

pH

Dissolved Oxygen (DO)

Turbidity

Conductivity / Salinity

ORP (Oxidation Reduction Potential)

Temperatura

All parameters are measured simultaneously and transmitted digitally to the analyzer.

Working with Water Quality Analyzer

The sensor is specifically designed for integration with Instrava multifunction water quality analyzers.

All measured parameters are digitally transmitted via RS-485, ensuring:

Stable signal transmission over long distances

No signal drift compared with analog sensors

Simplified wiring and commissioning

One analyzer can display, transmit, alarm, and log all parameters simultaneously.

Multi-Parameter Water Quality Sensor Key Advantages

7 parameters in one sensor – compact and space-saving

Digital RS-485 output – strong anti-interference performance

Automatic cleaning function – reduced maintenance frequency

Unified power supply – easy system integration

Factory-matched analyzer compatibility – plug-and-play deployment

Multi-Parameter Water Quality Sensor Typical Applications

Municipal water treatment plants

Industrial wastewater treatment

Chemical process water monitoring

Environmental monitoring stations

Power plants and energy facilities

Food & pharmaceutical water systems

Transmitters & Sensors Parameter

| Parámetro | pH Sensor | Dissolved Oxygen | Turbidity | Conductivity / Salinity | ORP | Temperatura |

|---|---|---|---|---|---|---|

| Rango de medición | 0 ~ 14 pH | 0 ~ 20 mg/L | 0 ~ 1000 NTU | 0 ~ 5000 µS/cm | -1500 mV ~ +1500 mV | 0 ~ 50 ℃ |

| Precisión | ±0.1 pH | ±0.3 mg/L | ±5% or ±3 NTU | ±1.5% F.S. | ±6 mV | ±0.3 ℃ |

| Resolución | 0.01 pH | 0.01 mg/L | 0.1 NTU | 1 µS/cm | 1 mV | 0.1 ℃ |

| Artículo | Especificación |

|---|---|

| Señal de salida | RS-485 (Modbus RTU) |

| Cleaning Method | Automatic cleaning |

| Fuente de alimentación | 12–24 VDC ±5% |

| Cable Length | Standard 10 m (customizable) |

Instrava OEM/ODM

At Instrava, we understand that water quality monitoring conditions vary significantly across industries and sites. Beyond standard products, we provide end-to-end customization and engineering support to ensure reliable performance in real-world applications.

Parameter Combination Customization

Customize measured parameters based on application needs (e.g., pH + DO + Turbidity + Conductivity).

Cable Length & Connector Options

Standard 10 m cable, extended or customized lengths available for deep wells, channels, or outdoor installations.

Cleaning System Optimization

Adjustable automatic cleaning cycles and cleaning methods for high-fouling or sludge environments.

Protocol & Integration Support

Modbus RTU register mapping optimization for PLC, DCS, and SCADA systems.

Mechanical & Mounting Adaptation

Custom brackets, immersion pipes, flow-through cells, or installation accessories upon request.

Pre-sales application evaluation

On-site or remote commissioning guidance

Calibration and maintenance recommendations

Long-term technical documentation and lifecycle support

Instrava sensors are designed not just to measure, but to operate stably over years of continuous service.

Yes. Each parameter uses an independent sensing element and digital signal processing.

All data are transmitted via RS-485, eliminating cross-interference common in analog multi-sensor systems.

RS-485 allows:

Multi-parameter transmission over one cable

Long-distance communication with strong anti-interference

Easy integration with PLC, SCADA, and DCS systems

No signal drift over time

This makes it ideal for complex water treatment and industrial environments.

Maintenance frequency depends on water quality.

With automatic cleaning enabled, typical inspection cycles are:

Clean water: 3–6 months

Wastewater or sludge: 1–3 months

Automatic cleaning significantly reduces manual intervention.

Yes. Calibration is performed through the connected Instrava water quality analyzer.

Step-by-step calibration guidance and output verification are supported to minimize operational errors.

Yes. The sensor is designed for continuous operation in industrial environments such as:

Chemical processing

Power plants

Municipal and industrial wastewater

Material selection and cleaning functions help maintain long-term stability.

Yes. Instrava multifunction analyzers can be configured to support:

Multiple sensors

Multiple monitoring points

Centralized data acquisition and alarm management

This is ideal for large-scale plants and distributed monitoring systems.

Al elegir Instrava, obtiene un socio con un profundo conocimiento de las aplicaciones industriales y la experiencia necesaria para hacer frente a los retos operativos actuales.

Nuestro papel va más allá de los productos: respaldamos su éxito con soluciones fiables y un compromiso a largo plazo.

La innovación en Instrava se guía por necesidades industriales reales. Perfeccionamos continuamente nuestras tecnologías para hacer frente a los cambiantes retos operativos, garantizando un rendimiento práctico y fiable en entornos exigentes.

Ofrecemos personalización a nivel de ingeniería para adaptarnos a las condiciones específicas del proceso. Desde el rango de medición y los materiales hasta las señales de salida y las opciones de instalación, nuestras soluciones están configuradas para adaptarse a aplicaciones reales.

La calidad y la fiabilidad son fundamentales en todos los productos Instrava. Fabricados bajo estrictos controles de calidad y sometidos a pruebas exhaustivas, nuestros instrumentos ofrecen un rendimiento preciso, estable y a largo plazo.

Instrava combina la experiencia mundial en ingeniería con una asistencia local receptiva, lo que garantiza que nuestros socios se beneficien de una tecnología alineada internacionalmente y de un servicio regional puntual.

Nuestra amplia cartera de instrumentos de medición y control nos permite dar respuesta a una amplia gama de necesidades industriales, proporcionando soluciones integradas a partir de una fuente única y fiable.

Trabajamos en estrecha colaboración con nuestros socios, desde el asesoramiento técnico hasta la asistencia posventa. Nos centramos en ofrecer soluciones que generen un valor duradero y contribuyan al éxito operativo a largo plazo.

How to Select the Right Approach for Reliable Process Control Why Sludge Concentration Measurement Matters Sludge concentration is a critical...

Long-term dissolved oxygen monitoring is fundamentally different from short-term measurement. While many dissolved oxygen sensors can deliver acceptable accuracy at...

Dissolved oxygen (DO) measurement is a critical parameter in water treatment, aquaculture, environmental monitoring, and industrial processes. Among available technologies,...

Instrava

Director de tienda

Mejor socio

Hola, ¿en qué puedo ayudarte hoy?