Transmisor

Inicio » Productos » Transmisores » Transmisor de presión diferencial

Transmisor de presión diferencial

The intelligent differential pressure transmitter adopts a high-precision capacitive sensor chip, using the most mature technology widely applied in international industrial markets. By integrating advanced production processes and modular design with all-patch-packaging components, this differential pressure transmitter achieves a compact, robust, and highly reliable structure.

Our intelligent differential pressure transmitters are available in three models: the normal analog model, the conventional smart model, and the standard smart model. The smart series differential pressure transmitters feature on-site adjustable settings via spot buttons, providing maximum flexibility for process monitoring. The devices are equipped with an LCD backlight, allowing easy reading even in low-light conditions. With a maximum measuring range ratio of 50:1, these differential pressure transmitters ensure accurate and stable measurement for liquids, gases, and steam in various industrial applications.

This diff pressure transmitter is ideal for process control, flow measurement, and pressure monitoring in chemical, petroleum, water treatment, HVAC, and power industries. The combination of intelligent technology and proven capacitive sensing makes it a reliable choice among differential pressure flow transmitters and other transmitter pressure differential devices.

Transmitter Description

Differential Pressure Transmitter Features

High-Precision Measurement: The intelligent differential pressure transmitter delivers highly accurate and stable readings with a two-wire system, ensuring reliable performance for industrial process control. This makes it ideal for differential pressure measurement in liquids, gases, and steam.

Maintenance-Free Design: With no mechanical moving parts, the differential pressure transmitter offers low maintenance and long-term durability. The capacitive sensor technology enhances stability, making it one of the most trusted differential pressure transmitters in the market.

Compact and Lightweight: The transmitter pressure differential features a compact, lightweight design, making installation simple and suitable for limited-space applications. Its modular construction ensures easy integration into pipelines, tanks, and process systems.

Smart Operation: Available in normal analog, conventional smart, and standard smart models, the intelligent differential pressure transmitter allows on-site adjustments via spot buttons. The LCD backlight enables convenient reading in low-light conditions, increasing operational efficiency.

Wide Measuring Range and Flexibility: With a maximum measuring range ratio of 50:1, the differential pressure flow transmitter can handle a wide variety of process conditions, providing precise and reliable flow, level, or pressure monitoring.

Robust Industrial Design: Constructed with advanced modular components and all-patch-packaging technology, the differential pressure transmitters are durable, compact, and resistant to harsh industrial environments, ensuring consistent transmitter pressure differential performance over time.

Pressure Transmitters Applications

The intelligent differential pressure transmitter is widely used across multiple industrial sectors due to its high accuracy, reliability, and compact design. Key applications include:

Flow Measurement: Differential pressure flow transmitters are ideal for monitoring liquid, gas, and steam flow in pipelines, ensuring precise process control in chemical, petroleum, and water treatment plants.

Level Monitoring: Differential pressure transmitters provide accurate liquid level measurement in pressurized tanks, vessels, and reservoirs, making them suitable for storage, processing, and chemical reaction monitoring.

Pressure Control: The transmitter pressure differential is used for continuous pressure monitoring in HVAC systems, boilers, and steam systems, helping maintain safe and efficient operations.

Industrial Process Automation: Intelligent differential pressure transmitters integrate seamlessly with control systems, enabling real-time monitoring, HART/Modbus communication, and process optimization in automated production lines.

Harsh Environment Applications: Designed with robust materials and modular construction, differential pressure transmitters can withstand corrosive, high-temperature, and high-pressure environments, making them suitable for petrochemical, power generation, and heavy industrial plants.

Energy Management and Efficiency: Differential pressure flow transmitters help monitor energy consumption in pipelines and fluid systems, supporting efficiency optimization and cost reduction initiatives.

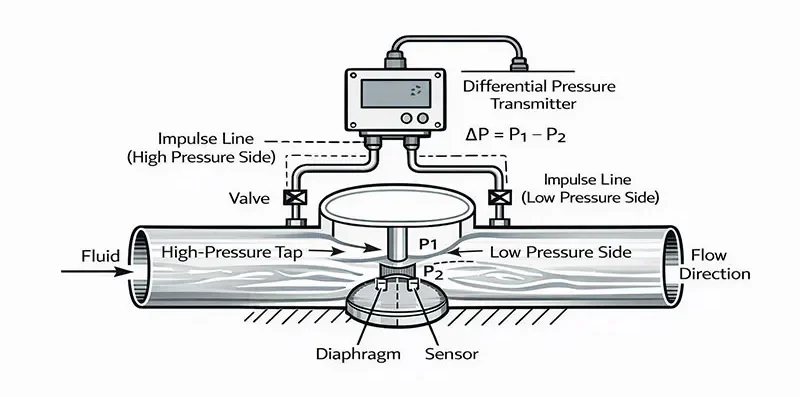

Transmitter Pressure Differential Measuring Principle

The intelligent differential pressure transmitter operates based on the principle of measuring the pressure difference between two points in a process. The capacitive sensor detects even minor changes in pressure and converts them into a proportional electrical signal. This signal is amplified and linearized, providing precise readings for transmitter pressure differential and differential pressure flow measurement. The smart series supports on-site calibration and adjustment, ensuring maximum accuracy across a wide range of industrial applications.

Differential Pressure Transmitters Structure

Sensor Element: High-precision capacitive chip, stable and durable for differential pressure measurement.

Housing: Compact, lightweight, and robust, made of stainless steel or aluminum to resist corrosion and high temperatures.

Electronics Module: Signal conditioning, HART or digital output for transmitter pressure differential integration.

Conexión a proceso: Flange, threaded, or sanitary fittings suitable for pipelines, tanks, and vessels.

Display Option: LCD backlight for easy reading in low-light conditions, available on smart series models.

Modular Design: All-patch-packaging components for compact, maintenance-free installation and high reliability.

Transmitter Parameter

| Measuring Range | 50Pa-10MPa |

| Precisión | 1. Digital Signal: ± 0.05; |

| 2. Analog signal: ± 0.075, ± 0.2, ± 0.5 | |

| 3. Micro range (≤ 1.5kPa): ± 0.2 | |

| Output Signal | 4-20mADC |

| Load Resistance | 0-600Ω (24VDC power) |

| Transmitting | > 1000m |

| Stability | ± 0.2% FS / Year ( t = 28 °C, the maximum static pressure 6.9 MPa, range 1:1 condition) |

| Power Influence | <0.005% / V |

| Power Supply | 12-45VDC |

| Temperatura de funcionamiento | -20-85 °C |

| Environment Temperature | -40 – +50 °C |

| Relative Humidity | 0-100% |

| Cable Perforation Lines | M20 × 1.5M or NPT1 / 2 ” |

| Sensor Fill Fluid: | Silicone oil, fluorine oil |

| Protection Class | IP67 |

| Explosion-proof Grade | 1. Intrinsically safe (i) Exia ii CT6 Ga |

| 2. Flameproof (d) Exd ii CT6 Gb |

Transmitter OEM/ODM

Personalización OEM / ODM

We provide comprehensive OEM/ODM services for differential pressure transmitters, including:

Custom measuring ranges and accuracy levels for specific industrial requirements.

Special materials and process connections for corrosive or high-pressure environments.

Integration with HART, Modbus, Profibus, and other digital protocols.

LCD/LED display customization and smart series on-site adjustment features.

Branding, packaging, and labeling customization for bulk orders.

Modular and compact design adjustments to meet client-specific installation needs.

A differential pressure transmitter measures the pressure difference between two points in a process system. It uses a capacitive sensor to convert the pressure differential into an electrical signal, which can be read locally or transmitted to a control system. Differential pressure transmitters are widely used for flow measurement, level monitoring, and pressure control in liquids, gases, and steam.

Intelligent differential pressure transmitters typically come in three models: normal analog, conventional smart, and standard smart. The smart series features on-site adjustable settings via spot buttons and LCD backlight for easy reading. These diff pressure transmitters can handle a maximum measuring range ratio of 50:1, making them suitable for diverse industrial applications.

Differential pressure flow transmitters and transmitter pressure differential devices are used in chemical, petrochemical, HVAC, water treatment, power generation, and food processing industries. They are ideal for accurate flow, level, and pressure monitoring in pipelines, tanks, and vessels, providing real-time data for process automation and control.

Intelligent differential pressure transmitters offer high precision with accuracy levels of ±0.1% to ±0.5% FS. The capacitive sensor design, combined with robust modular construction, ensures stable long-term performance and low maintenance. These diff pressure transmitters are reliable even in harsh industrial environments.

Yes, OEM/ODM customization is available for differential pressure transmitters. Customers can request customized measuring ranges, process connections, materials for corrosive environments, digital communication protocols (HART, Modbus, Profibus), and smart series features such as LCD display and on-site adjustment.

Intelligent differential pressure transmitters offer several advantages: no mechanical moving parts for low maintenance, compact and lightweight design for easy installation, high-precision capacitive sensors for accurate readings, and smart series functionality for on-site adjustment and monitoring. They provide superior performance in flow, level, and pressure measurement compared to conventional transmitter pressure differential devices.

Por qué elegir Instrava

Al elegir Instrava, obtiene un socio con un profundo conocimiento de las aplicaciones industriales y la experiencia necesaria para hacer frente a los retos operativos actuales.

Nuestro papel va más allá de los productos: respaldamos su éxito con soluciones fiables y un compromiso a largo plazo.

Innovación impulsada por la ingeniería

La innovación en Instrava se guía por necesidades industriales reales. Perfeccionamos continuamente nuestras tecnologías para hacer frente a los cambiantes retos operativos, garantizando un rendimiento práctico y fiable en entornos exigentes.

Personalización específica de la aplicación

Ofrecemos personalización a nivel de ingeniería para adaptarnos a las condiciones específicas del proceso. Desde el rango de medición y los materiales hasta las señales de salida y las opciones de instalación, nuestras soluciones están configuradas para adaptarse a aplicaciones reales.

Calidad y fiabilidad demostradas

La calidad y la fiabilidad son fundamentales en todos los productos Instrava. Fabricados bajo estrictos controles de calidad y sometidos a pruebas exhaustivas, nuestros instrumentos ofrecen un rendimiento preciso, estable y a largo plazo.

Capacidad global con apoyo local

Instrava combina la experiencia mundial en ingeniería con una asistencia local receptiva, lo que garantiza que nuestros socios se beneficien de una tecnología alineada internacionalmente y de un servicio regional puntual.

Amplia cartera de productos

Nuestra amplia cartera de instrumentos de medición y control nos permite dar respuesta a una amplia gama de necesidades industriales, proporcionando soluciones integradas a partir de una fuente única y fiable.

Asistencia técnica orientada a los socios

Trabajamos en estrecha colaboración con nuestros socios, desde el asesoramiento técnico hasta la asistencia posventa. Nos centramos en ofrecer soluciones que generen un valor duradero y contribuyan al éxito operativo a largo plazo.