Émetteur

Accueil » Produits » Transmetteurs » Transmetteur de niveau à flotteur pour une mesure fiable du niveau de liquide

Transmetteur de niveau à flotteur pour une mesure fiable du niveau de liquide

The float level transmitter is a reliable and accurate level measurement instrument designed for continuous liquid level monitoring in industrial tanks, vessels, and process systems. By detecting liquid level changes through the movement of a float, the float level transmitter converts the mechanical displacement into a stable electrical output signal for process control and monitoring.

Float level transmitters are widely used due to their simple structure, stable performance, and adaptability to various liquids. With different material options and output signals, the float level transmitter is suitable for industrial applications requiring dependable level measurement under demanding operating conditions.

Transmitter Description

Main Features of Float Level Transmitter

Stable and accurate liquid level measurement

Simple mechanical structure with high reliability

Suitable for various liquids and process media

Multiple output signal options (analog or digital)

Wide operating temperature and pressure range

Installation et entretien faciles

Customizable probe length and mounting options

Long service life with minimal maintenance

These features make the float level transmitter an ideal choice for continuous level monitoring in industrial environments.

Typical Applications of Float Level Transmitters

Float level transmitters are commonly used in:

Industrial storage tanks

Chemical processing systems

Water and wastewater treatment plants

Oil and fuel storage tanks

Power generation facilities

Process control systems

The robust design of float level transmitters ensures reliable operation in both indoor and outdoor industrial applications.

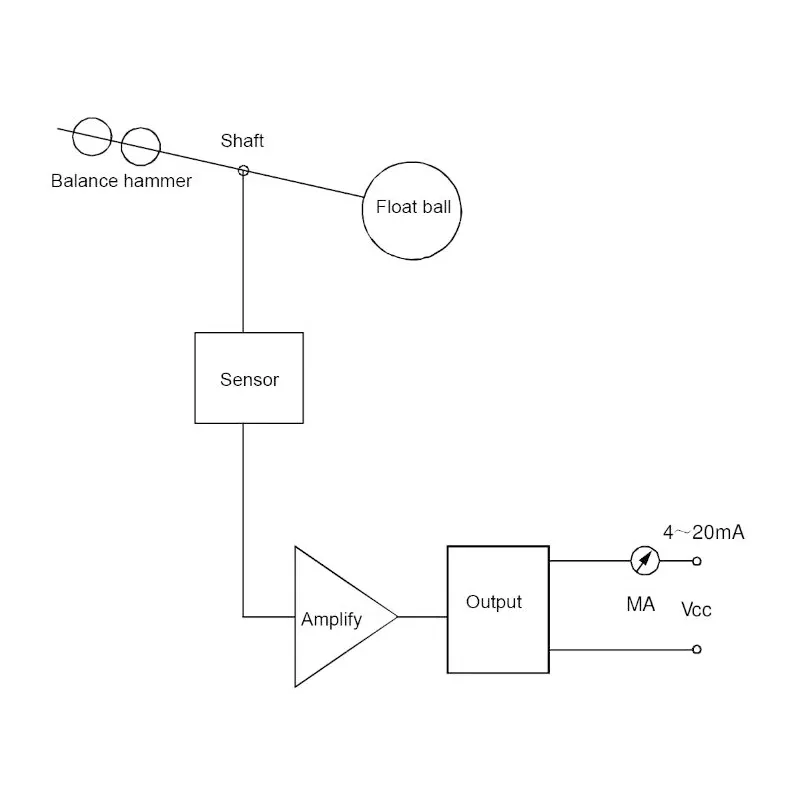

Working Principle of Float Level Transmitter

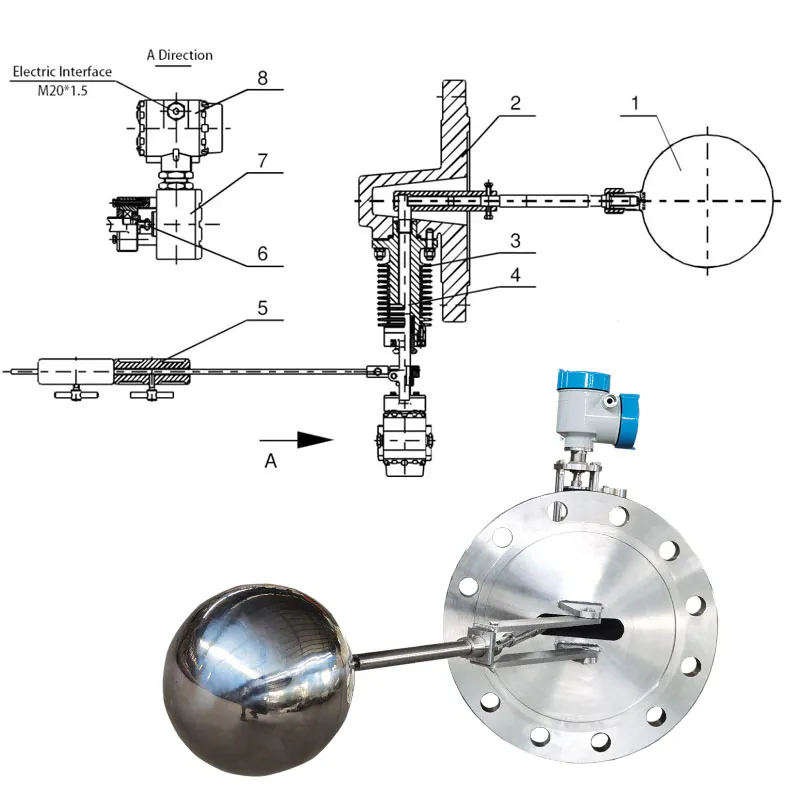

The float level transmitter consists of two main parts: the level measuring mechanism and the electrical transmission unit (meter head).

The level measuring mechanism includes a measuring float, float rod, balance hammer, and balance rod. These components form a torque balance system, allowing the float to move freely up and down in response to changes in the liquid level.

When the liquid level rises or falls, the float moves accordingly and drives the main shaft to rotate. The main shaft is axially connected to the angular displacement sensor located in the meter head, forming a synchronized mechanical transmission system.

As the main shaft rotates, the angular displacement sensor converts the shaft’s angular movement into an electrical signal. The electronic circuit inside the meter head then processes this signal and outputs a standard 4–20 mA current signal that is directly proportional to the actual liquid level.

This design ensures accurate, stable, and continuous level measurement under normal operating conditions.

Float Type Level Transmitter Structural Composition

A typical float level transmitter consists of:

Float (stainless steel or plastic)

Guide rod or stem

Level sensing element

Transmitter housing

Electrical connection interface

Process mounting (flange or thread)

The compact and modular structure enables easy installation and flexible customization.

Transmitter Parameter

| Objet | Spécifications |

|---|---|

| Modèle | INFLT114 |

| Measuring Function | Liquid level |

| Plage de mesure | Large-angle type: 450 – 1600 mm Small-angle type: 380 – 1200 mm |

| Measurement Accuracy | ±1.5% of full scale (FS) |

| Supply Voltage | 24 V DC (12.7 – 27.2 V DC) |

| Signal de sortie | 4 – 20 mA DC |

| On-site Indication | Multi-parameter LCD display (intelligent) 0 – 100% (4 – 20 mA) moving coil display (analog type) |

| Explosion-proof Rating | Flameproof: Ex d IIC T4 Intrinsically Safe: Ex ia IIC T4 |

| Protection Class | IP67 |

| Température ambiante | –20 °C to +60 °C |

| Ambient Humidity | ≤ 95% RH |

| Process Medium Temperature | –40 °C to +225 °C (without heat sink) +225 °C to +450 °C (with heat sink) |

| Minimum Medium Density | ≥ 0.55 g/cm³ |

| Working Pressure | 2.5 MPa / 4.0 MPa / 6.4 MPa |

| Raccordement au processus (bride) | Standard: DN250 PN, JB/T 82.2-94 (raised face) Special: DN200 PN, JB/T 82.2-94 (convex face) |

| Cable Entry (Outlet) | M20 × 1.5 (internal thread) |

| Electrical Enclosure | Die-cast aluminum alloy with powder coating |

| Float Maximum Running Angle | Small-angle type: 35° Large-angle type: 80° |

| Wetted Parts Material | Standard: 1Cr18Ni9Ti Optional: 316 / 316L |

Transmitter OEM/ODM

Personnalisation et service OEM

Float level transmitters can be customized to meet specific application requirements, including:

Measuring range and probe length

Material selection for float and stem

Output signal and communication protocol

Mounting type and connection standard

Explosion-proof or high-temperature design

Instrava is a partner focused on providing equipment, solutions, and services for industrial measurement and control instruments used in safety-critical and process control applications. We are committed to delivering reliable and long-lasting solutions based on trust, communication, and collaboration, helping customers improve process efficiency and operational reliability.

As a trusted long-term partner for customers and OEM partners in China, Instrava provides professional OEM and customization services for float level transmitters and other industrial level measurement solutions.

A float level transmitter is used for continuous liquid level measurement in industrial tanks, vessels, and process systems. It converts the movement of a float into an electrical output signal for monitoring and process control.

A float level transmitter works based on the buoyancy principle. As the liquid level changes, the float moves up or down and transfers the movement to a sensing element, which converts it into an electrical signal such as 4–20 mA.

Float level transmitters can measure a wide range of liquids, including water, oils, fuels, chemicals, and other industrial fluids, provided the liquid density and material compatibility are suitable for the float and stem materials.

Common output signals for float level transmitters include 4–20 mA, 0–10 V, and switch outputs. Customized signal options are also available to meet specific control system requirements.

Yes. Float level transmitters can be customized in terms of measuring range, probe length, material selection, mounting type, output signal, and protection level to match different tank sizes and process conditions.

Float level transmitters are designed for industrial use and can operate under high temperature, pressure, and corrosive conditions when proper materials and sealing options are selected. They are widely used in chemical, oil & gas, and power generation industries.

Pourquoi choisir Instrava ?

En choisissant Instrava, vous bénéficiez d'un partenaire ayant une connaissance approfondie des applications industrielles et l'expertise nécessaire pour relever les défis opérationnels d'aujourd'hui.

Notre rôle va au-delà des produits - nous soutenons votre réussite grâce à des solutions fiables et à un engagement à long terme.

L'innovation par l'ingénierie

L'innovation chez Instrava est guidée par les exigences industrielles réelles. Nous affinons continuellement nos technologies pour répondre aux défis opérationnels en constante évolution, en garantissant des performances pratiques et fiables dans des environnements exigeants.

Personnalisation en fonction de l'application

Nous offrons une personnalisation au niveau de l'ingénierie pour répondre aux conditions spécifiques du processus. De la plage de mesure et des matériaux aux signaux de sortie et aux options d'installation, nos solutions sont configurées pour s'adapter aux applications réelles.

Une qualité et une fiabilité éprouvées

La qualité et la fiabilité sont fondamentales pour chaque produit Instrava. Fabriqués sous un contrôle de qualité strict et testés de manière approfondie, nos instruments offrent des performances précises, stables et à long terme.

Une capacité mondiale avec un soutien local

Instrava associe une expertise technique mondiale à un support local réactif, garantissant à nos partenaires une technologie alignée au niveau international et un service régional opportun.

Un portefeuille de produits complet

Notre large gamme d'instruments de mesure et de contrôle nous permet de répondre à un grand nombre de besoins industriels, en fournissant des solutions intégrées à partir d'une source unique et fiable.

Soutien technique axé sur les partenaires

Nous travaillons en étroite collaboration avec nos partenaires, de la consultation technique à l'assistance après-vente. Notre objectif est de fournir des solutions qui créent une valeur durable et soutiennent le succès opérationnel à long terme.