Level Measuring Instruments

Home » Products » Level Measuring Instruments » Magnetic Level Sensor-Oil Gas Storage Tank

Magnetic Level Sensor-Oil Gas Storage Tank

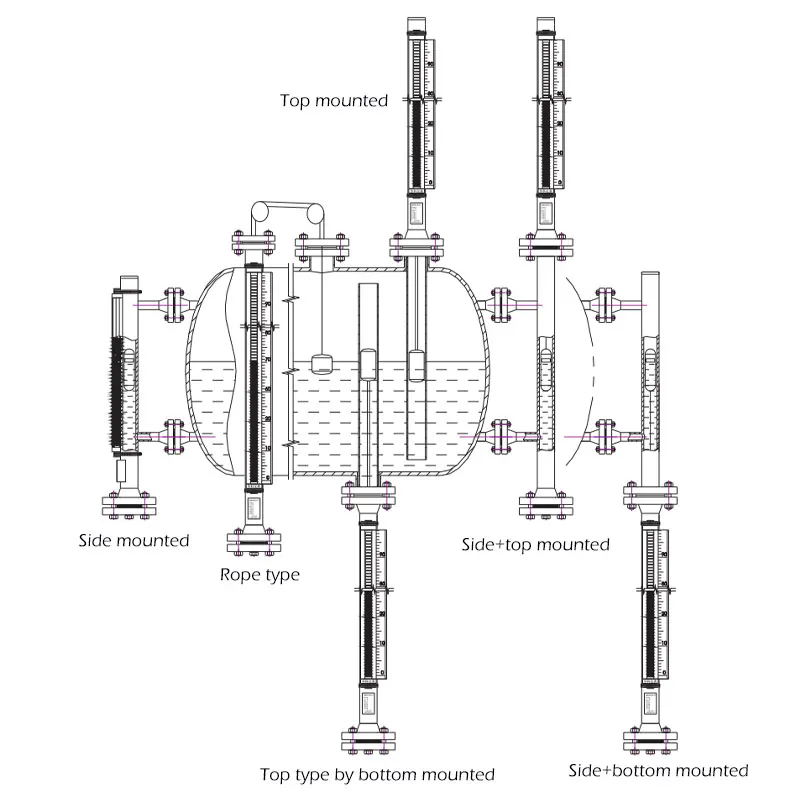

Magnetic level gauge is a robust and reliable solution for continuous liquid level measurement in safety-critical and process control applications. Designed for harsh industrial environments, it provides clear visual indication and stable signal output without being affected by the physical or chemical properties of the medium, such as conductivity, dielectric constant, foam, or vapor.

Based on a proven magnetic coupling principle, the magnetic level gauge ensures accurate level monitoring for corrosive, toxic, flammable, or high-temperature liquids. It supports both single-phase level measurement and interface measurement of two liquids with different densities, making it suitable for complex industrial processes.

As a long-term partner in industrial measurement and control, Instrava supplies magnetic level gauges as part of complete level measurement solutions. By combining reliable products, flexible OEM / ODM capabilities, and close technical collaboration, we help customers improve process safety, operational efficiency, and system reliability. Instrava works closely with customers and OEM partners to deliver long-lasting magnetic level solutions tailored to real operating conditions.

Level Measuring Instruments Description

Magnetic Level-Features

Simple and robust design: The level indicator magnetic type features a straightforward structure, ensuring high stability, reliability, and long-term operation in industrial applications.

Medium-independent performance: Accurate measurement regardless of the liquid’s physical or chemical properties, including conductivity, dielectric constant, foam, or viscosity.

Suitable for harsh environments: Compatible with corrosive, toxic, and explosive media, providing safe and maintenance-free level monitoring.

Dual-medium interface measurement: Capable of measuring the interface or level of two liquids with different densities, ideal for chemical and petrochemical processes.

Flexible display and output: Supports two-wire 4–20 mA DC signal output and optional LED digital displays (0.56″ or 0.8″), enabling easy integration with control systems and remote monitoring.

Level Magnetic-Applications

Magnetic level gauges are widely used across diverse industrial settings, providing accurate and reliable liquid level monitoring:

Steam and hot water boilers, ensuring safe and precise water level control.

Wastewater treatment systems, offering corrosion-resistant and maintenance-free monitoring.

Filling and unloading containers in chemical, pharmaceutical, and food industries.

Chemical and petrochemical storage tanks, capable of handling corrosive and hazardous liquids.

Petroleum and petroleum product tanks, maintaining safe and accurate level measurement.

Oil-fired boilers and diesel fuel tanks, supporting energy and power generation facilities.

Generator sets and auxiliary fuel storage, ensuring reliable operation in remote or industrial sites.

Marine and aerospace fuel tanks, including submarines, helicopters, and ships, where space-efficient and safe level measurement is critical.

Magnetic Level Gauge-Measuring Principle

The magnetic level gauge consists of a measuring body, dual-colored display cylinder, scale, top and bottom flanges, magnetic float, and optional 4–20 mA transmitter. Based on the buoyancy principle, the magnetic float rises or falls with the liquid level, causing the dual-colored display cylinder to rotate and visually indicate the liquid level.

Each display cylinder features a two-color, axisymmetric design with a 10 mm distance between cylinders: the red side represents liquid, while the white side represents air. In addition to standard liquid level measurement, the magnetic level gauge can also accurately measure the interface between two liquids of different densities, making it ideal for chemical, petrochemical, and industrial applications.

Magnetic Levels-Product Structure

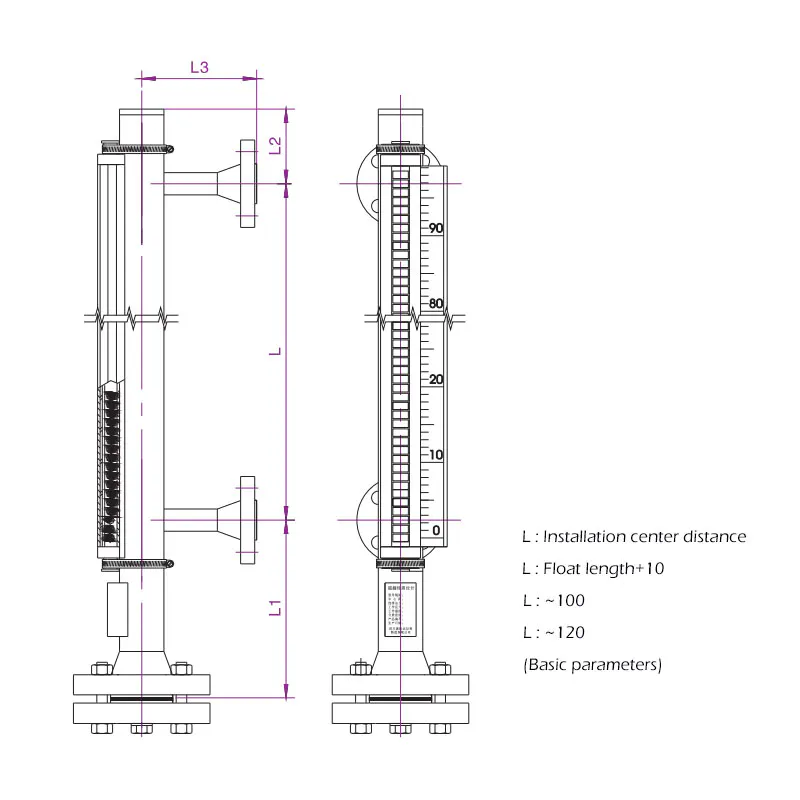

The magnetic level gauge features a modular and durable structure designed for reliable liquid level measurement in industrial environments. Its main components include:

Measuring Body: Houses the magnetic float and provides the chamber for the liquid, built from corrosion-resistant materials such as stainless steel or carbon steel with optional PTFE lining.

Magnetic Float: Moves with the liquid level based on buoyancy, transmitting the position to the external indicator via magnetic coupling.

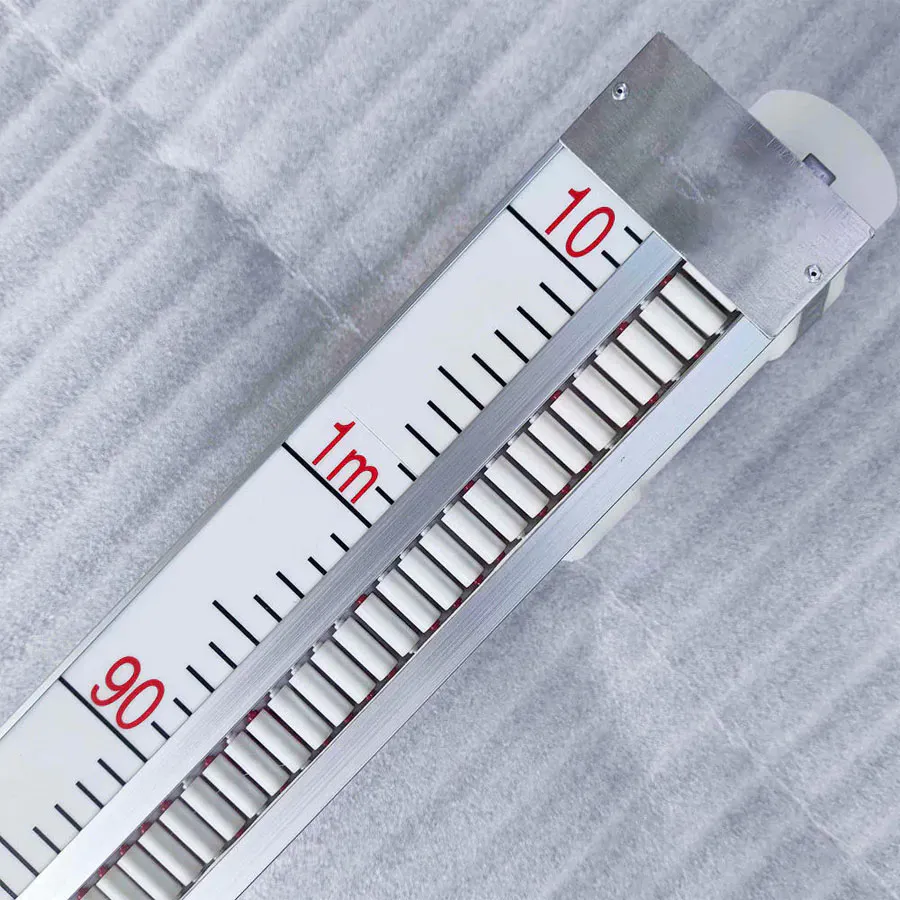

Dual-Colored Display Cylinder: Shows liquid (red) and air (white) levels with a clear, axisymmetric design, enabling intuitive visual reading.

Scale/Ruler: Provides precise reference for manual level reading.

Top and Bottom Flanges: Allow secure mounting to tanks or vessels, ensuring leak-free operation.

Optional Transmitter (4–20 mA): Converts liquid level changes into electrical signals for remote monitoring and integration with control systems.

This structure ensures that the magnetic level gauge operates reliably in harsh conditions, supports interface measurement between different liquids, and provides maintenance-free, long-term level monitoring.

Level Measuring Instruments Parameter

| Measuring Range | 150~6000mm(Over 6M, customization is available) |

| Working Pressure | PN2.5~PN160 (x 0.1MPa) |

| Working Temperature | -190 ~ +425 °C |

| Connection Method | DN80-DN250/RF/14(according to the density of medium) |

| Pressure of Stream | ≤0.6mpa(please note when >0.6mpa) |

| Connector of Heating Stream | R1/2″ male thread or customize |

| Communication | 4~20mADC |

| Medium Density | >0.45g/cm3 |

| Main Materials | 304,316L,304+PTFE,0Cr18Ni9,00Cr17Ni14Mo2,PP(PP≤1.6mpa, 304+PTFE≤4mpa), or customize |

| Protection Class | IP65 |

| Customized | LED Display and Solar Powered |

Arange 0.15-12m Temperature -190 ~ +425 °C Output signal: 4~20mAdc

Level Measuring Instruments OEM/ODM

Magnetic Level Gauges -OEM ODM

We offer customized magnetic level gauges and optional liquid level transmitters to meet diverse industrial requirements:

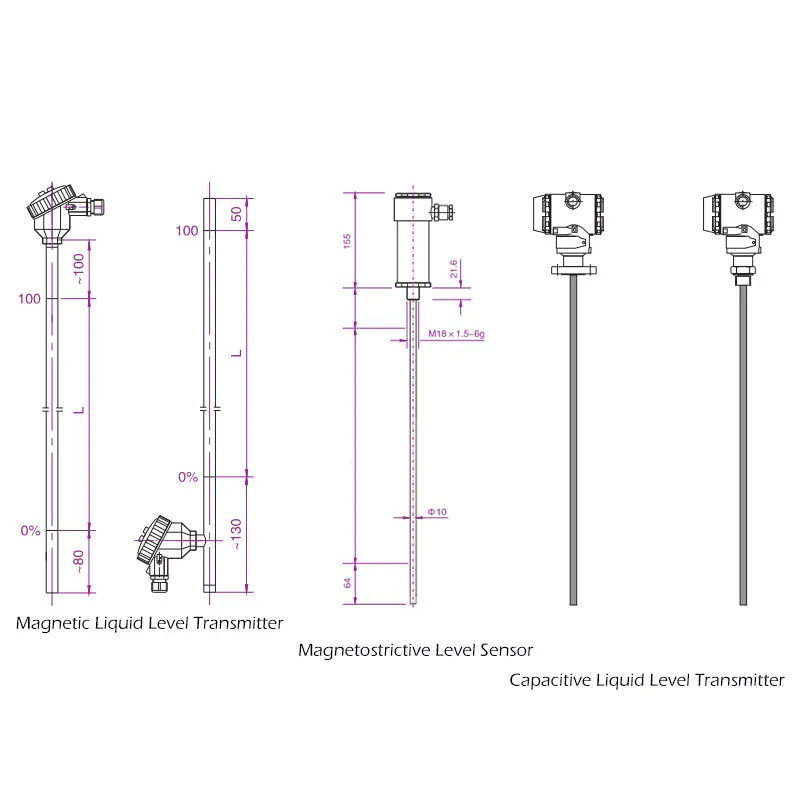

Optional Liquid Level Transmitters:

Magnetic Transmitter: Uses an imported reed switch and precision circuit to convert magnetic float movement into a 4–20 mA signal for accurate liquid level detection.

Capacitive Transmitter: Installed in the bypass tube, it provides continuous, float-independent signal output, enhancing reliability.

Magnetostrictive Sensor: High-accuracy sensor unaffected by gas, temperature, or pressure changes, with 4–20 mA, HART, or Modbus output options.

Optional Magnetic Alarm Switch:

Made from high-quality reed switches (SPDT/SPST), the magnetic switch triggers stable on/off signals as the float passes, requiring no external power. Ideal for alarms and automatic control of liquid levels and interfaces.

Related Product Recommendations

A magnetic level gauge is a robust, non-contact level measurement device that uses a float with a magnetic core to indicate liquid levels inside a chamber. The magnetic field actuates an external visual indicator or transmitter, providing accurate, safe, and reliable readings.

Manufacturer advantages:

No direct contact with the measured medium, reducing corrosion and maintenance

Accurate readings under high pressure (up to 40 MPa) and temperature (up to 400°C)

Suitable for hazardous, corrosive, or viscous fluids

Long service life with minimal downtime

Magnetic level gauges are widely used where precision and safety are critical:

Oil & Gas: Crude oil, LPG, and refined products storage tanks

Chemical: Strong acids, alkalis, and solvent tanks

Pharmaceutical: Process reactors and hygienic tanks compliant with GMP

Example: A chemical plant using a magnetic level gauge for corrosive acid tanks reported zero downtime over 5 years, demonstrating reliability in harsh conditions.

| Feature | Magnetic Level Gauge | Radar Level Gauge | Ultrasonic Sensor |

|---|---|---|---|

| Contact | Float inside chamber | Non-contact | Non-contact |

| Accuracy | ±1–5 mm | ±1–3 mm | ±5–10 mm |

| Maintenance | Very low | Low | Medium |

| Harsh conditions | Excellent (corrosive, high temp) | Excellent | Limited |

| Visual indication | Yes, mechanical | Optional | No |

Manufacturer note: Magnetic level gauges excel in high-pressure, corrosive, or opaque fluids where radar signals may be less effective.

Yes. Industrial-grade magnetic level gauges can operate under:

Pressure: Up to 40 MPa

Temperature: Up to 400°C

Hazardous environments: ATEX/IECEx certified options

They are ideal for energy & power plants, chemical reactors, pharmaceutical sterilizers, and HVAC thermal storage tanks.

Energy & Power: Boiler feedwater and condensate tanks

Marine & Shipping: Fuel, ballast, and cargo tanks

Automotive: Coolant, chemical storage, and paint process tanks

Environmental & Mining: Slurry, tailings, and wastewater tanks

HVAC Systems: Chilled water and hot water storage tanks

Manufacturer perspective: Magnetic level gauges are chosen for high reliability, visual verification, and low maintenance in demanding industrial applications.

Process fluid characteristics: Corrosive, opaque, viscous

Operating conditions: Temperature, pressure, and vibration

Chamber material: Stainless steel, PTFE lining, or alloy for chemical resistance

Indicator type: Flap, column, or transmitter

Certification: ATEX, IECEx, FDA, GMP as required

Correct selection ensures accurate measurement, operator safety, and long-term operational efficiency.

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.