Level Measuring Instruments

Home » Products » Level Measuring Instruments » Magnetostrictive Level Sensor

Magnetostrictive Level Sensor

The Magnetostrictive Level Gauge is a high-precision solution designed for continuous liquid level and interface measurement in demanding industrial environments. Based on proven magnetostrictive technology, it delivers stable, repeatable and highly accurate measurement results over long-term operation.

This level gauge is particularly suitable for storage tanks, pressure vessels and process applications where reliable level data is critical for safety, inventory management and process control. By directly measuring the position of the magnetic float through time-of-flight detection along the waveguide, the system provides real-time level information that is unaffected by changes in temperature, pressure, density or electrical properties of the medium.

With its robust mechanical structure and flexible configuration options, the magnetostrictive level gauge supports both single liquid level and oil–water interface measurement in the same tank. Multiple output signals and communication protocols allow seamless integration into DCS, PLC and SCADA systems, making it an ideal choice for modern industrial automation.

Designed from a manufacturer’s perspective, the instrument can be customized in measuring length, materials, process connections and signal outputs to match specific application requirements. It is widely applied in oil & gas, chemical, petrochemical, power and tank farm systems where accuracy, reliability and long service life are essential.

Level Measuring Instruments Description

Magnetostrictive Level Sensor-Features

High-accuracy and high-repeatability measurement ensures stable and reliable long-term performance.

Supports multiple output signals and communication protocols for seamless system integration.

Zero and span adjustable across 100% of the measuring range for easy commissioning.

Advanced anti-RF interference and lightning protection design for harsh industrial environments.

Maintenance-free operation with no periodic calibration required.

Rigid probe structure provides excellent pressure resistance for demanding process conditions.

Flexible probe option enables ultra-long measuring ranges while simplifying transportation and installation.

Corrosion-resistant construction ensures reliable operation in aggressive and corrosive media.

Magnetostrictive Level Gauge Application – Storage Tank Level & Interface Measurement

Magnetostrictive level gauges are widely used for continuous liquid level and interface measurement in storage tanks and process vessels where high accuracy and long-term reliability are required.

In oil & gas, petrochemical and chemical industries, the gauge provides precise monitoring of liquid level and oil–water interface in crude oil tanks, product tanks, and separation vessels. Accurate level data helps prevent overfilling, optimize inventory management, and improve operational safety.

For tank farms and bulk storage systems, the magnetostrictive level gauge supports long measuring ranges and stable performance under varying temperature and pressure conditions. Maintenance-free operation reduces downtime and lowers total cost of ownership, making it a cost-effective solution for large-scale installations.

With flexible probe designs, corrosion-resistant materials, and multiple signal outputs, the instrument can be easily integrated into existing control systems, ensuring reliable operation in both new projects and retrofit applications.

Magnetostrictive Liquid Level Sensor-Working Principle

The transmitter sends a short excitation pulse along the magnetostrictive waveguide.

A magnetic float moves with the liquid level and generates a static magnetic field.

When the pulse reaches the float, a torsional wave is generated at that position.

The torsional wave travels back to the transmitter at a constant speed.

The time difference is calculated to determine the exact liquid level or interface position.

Magnetostrictive Level Sensors-Structure

Electronics Housing

Integrated signal processing and transmitter module for level and interface measurement. Supports standard analog and digital outputs with optional local display. Industrial-grade enclosure suitable for field installation.

Magnetostrictive Waveguide

High-stability waveguide wire for excitation pulse transmission and torsional wave detection. Ensures accurate time-of-flight measurement independent of process temperature, pressure or medium properties.

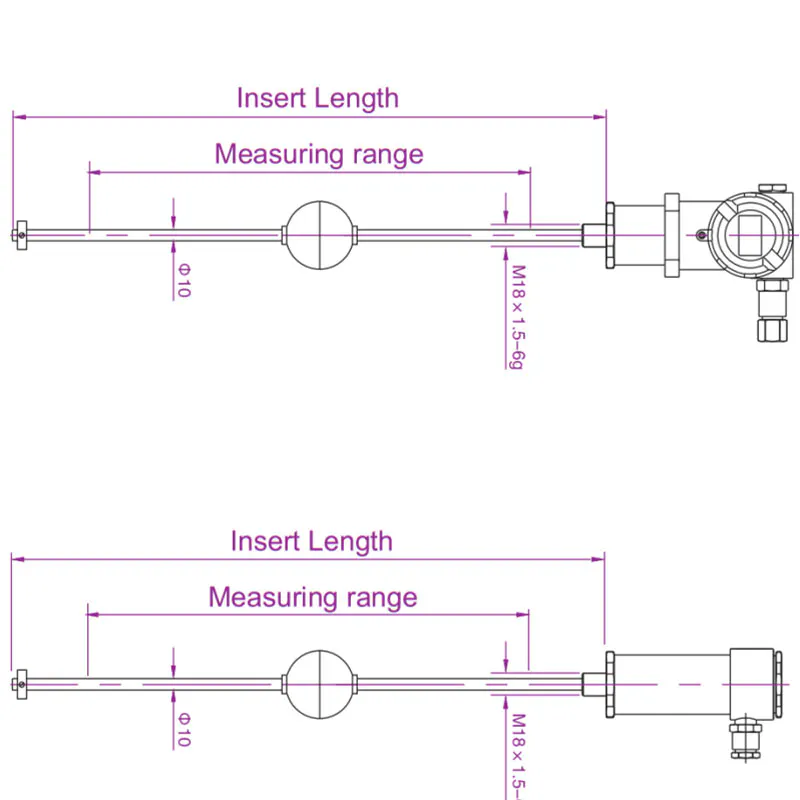

Measuring Probe

Available in rigid rod or flexible cable design. The rigid probe offers high mechanical strength and pressure resistance, while the flexible probe is suitable for ultra-long measuring ranges and simplified transportation and installation.

Magnetic Float

Free-moving float with built-in permanent magnet. Float size and material are selected according to medium density and process pressure to ensure stable operation and measurement accuracy.

Process Connection

Threaded or flanged mounting options available. Multiple standards and pressure ratings supported to meet different vessel and tank installation requirements.

Electrical Connection

Standard electrical interfaces including M20×1.5, 1/2″ NPT, direct cable outlet, aviation connector or terminal block for reliable field wiring.

Level Measuring Instruments Parameter

| Item | Specification |

|---|---|

| Measuring Range | Rigid type: 50–5000 mmFlexible type: 4000–20000 mm (longer lengths available upon request) |

| Measurement Accuracy (Non-linearity) | < 0.05% F.S.For ranges ≤ 300 mm: up to 150 μm |

| Repeatability | < 0.01% F.S. |

| Resolution | 1 mm standard5 μm (high-precision version) |

| Hysteresis | < 0.01% F.S. |

| Temperature Influence | < 0.007% F.S. / °C |

| Zero Adjustment Range | 100% F.S. |

| Span Adjustment Range | 100% F.S. |

| Float & Probe Material | SS304, SS316, SS304 + PTFE |

| Electronics Housing Material | SS304 or aluminum alloy (with local display and HART option) |

| Process Connection | Threaded or flanged |

| Power Supply | 24 VDC |

| Operating Temperature | –40 to +85 °C |

| Storage Temperature | –40 to +100 °C |

| Nominal Pressure Rating | PN2.5 to PN160 (×0.1 MPa)Up to PN250 available for special applications |

| Output Signal | 4–20 mA DCModbus0–10 V DC / 0–5 V DC (optional) |

| Load Resistance | ≤ 500 Ω |

| Electrical Connection | M20×1.51/2” NPTDirect cable outletAviation connectorTerminal block |

| Applicable Medium Density | ≥ 0.5 g/cm³Lower density available upon request |

| Float Diameter | Ø24–Ø120 mm (selected based on pressure and medium density) |

| Ingress Protection | IP65 |

| Explosion Protection | Ex ia IIC T6 GaEx d IIC T6 Gb |

Level Measuring Instruments OEM/ODM

Magnetostrictive Level Sensor – OEM/ODM

Custom Solutions for Your Application

We specialize in providing OEM and ODM magnetostrictive level sensors tailored to your specific industrial requirements. From measuring range and probe materials to signal outputs and process connections, every component can be customized to ensure seamless integration with your systems.

Flexible Measuring Range

Rigid probes: 50–5000 mm

Flexible probes: 4000–20000 mm (longer lengths available on request)

Custom ranges and designs available for special applications

Material & Process Customization

Probe & float materials: SS304, SS316, SS304+PTFE

Electronics housing: SS304 or aluminum alloy with optional local display and HART

Process connections: Threaded, flanged, or customer-specific solutions

Corrosion-resistant and high-pressure options for harsh environments

Signal & Communication Options

Standard outputs: 4–20 mA, 0–10 V, 0–5 V

Digital communication: Modbus, HART, other protocols available

Configurable for easy integration with PLC, DCS, SCADA systems

Related Product Recommendations

It provides highly accurate and stable level measurement, reducing process downtime and minimizing inventory errors. Its long-term reliability ensures a strong return on investment compared with conventional gauges.

Yes, its non-contact time-of-flight measurement eliminates mechanical wear, requiring no periodic calibration. This significantly lowers maintenance labor and operational costs over the product lifetime.

OEM/ODM options allow adjustment of probe length, materials, process connections, and outputs. This ensures seamless integration into existing tanks, vessels, and control systems, reducing retrofit costs.

Absolutely. The gauge supports 4–20 mA, HART, and Modbus outputs, allowing easy integration with PLC, DCS, and SCADA systems for real-time monitoring and automated control.

Constructed from corrosion-resistant materials with rugged probes, the gauge performs reliably under high pressure, extreme temperatures, and aggressive chemical conditions, ensuring consistent operation and long-term value.

Accurate and repeatable measurements reduce overfilling, waste, and downtime. Flexible installation options and long-range probes optimize system layout, making your process safer, more efficient, and cost-effective.

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.