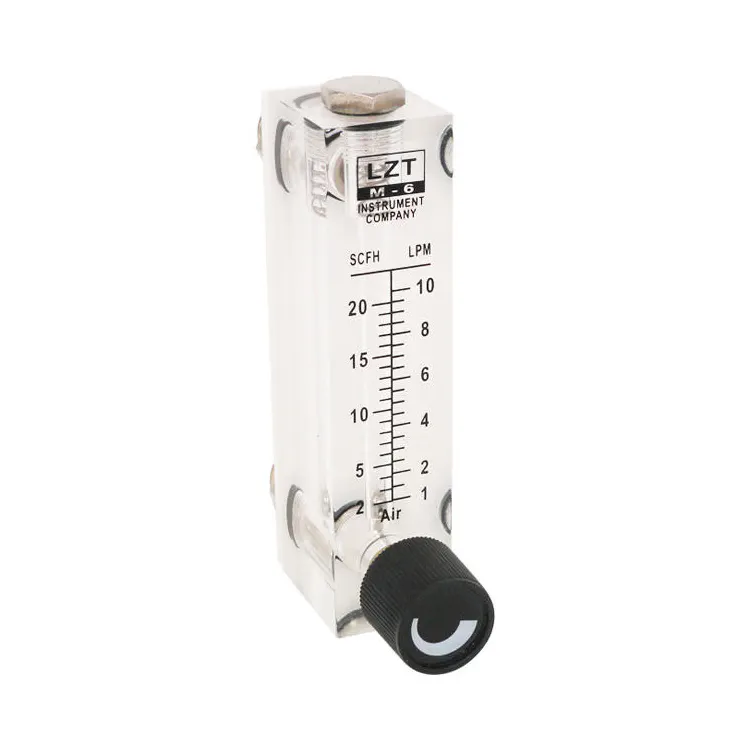

Variable Area Rotameter Acrylic Flow Meter

Instrava’s acrylic body variable area flow meters provide an ideal balance of cost efficiency, measurement accuracy, and wide flow range availability. Designed to cover applications from microflow to larger flow rates, these variable area rotameters offer a practical solution for many industrial flow measurement needs.

The flow meter features a one-piece transparent acrylic body with PVC or metal process fittings, ensuring durability while allowing clear visual observation of flow conditions. A large, easy-to-read scale with additional reference marks improves readability and reduces interpretation errors during operation.

Low flow models use an inherently stable float design, while higher flow models incorporate a float stabilization mechanism for enhanced indication stability. Many models are available with or without integrated control valves, combining accuracy, value, and low cost in a compact and reliable flow measurement solution.

Flow Meter Description

Acrylic Body Variable Area Flow Meters Features

Clear, high-contrast scales for fast and accurate flow reading

Compact and lightweight design for easy installation in limited spaces

Durable acrylic body with robust fittings for long-term operation

Cost-effective flow measurement solution for standard industrial applications

Metric scales available as standard or optional configuration

Air sampling and gas analysis equipment

Aquaculture and water treatment systems

Desalination and filtration processes

Medical and laboratory equipment

OEM and skid-mounted systems

Variable Area Rotameter Application Scenarios

The variable area rotameter (acrylic flow meter) is widely used for visual flow monitoring in systems requiring simple, reliable, and cost-effective flow indication. Typical applications include:

Air sampling and gas analysis systems

Aquaculture and water treatment processes

Desalination and filtration systems

Medical and laboratory equipment

Chemical dosing and fluid handling systems

OEM equipment and skid-mounted assemblies

Rotameter Working Principle

The variable area rotameter operates on the variable area principle. The fluid flows upward through a vertically mounted, tapered acrylic tube. As the flow rate increases, the float rises until the upward force from the fluid equals the gravitational force acting on the float.

The height of the float within the tube corresponds directly to the flow rate, which is read against a calibrated scale on the acrylic tube. This mechanical measurement method provides stable and repeatable flow indication without the need for external power.

Rotameter Flow Meter Structure

The acrylic flow meter consists of a precision-molded acrylic tapered tube, a corrosion-resistant float, end fittings, and sealing components. The lightweight and transparent structure allows easy visual inspection while maintaining sufficient mechanical strength for low-pressure applications.

Flow Meter Parameter

Model: INAR115 (Customizable)

| Item | Specification |

|---|---|

| Measuring Medium | Liquid / Gas |

| Measuring Range – Liquid | ml/min: 6–60, 8–80, 30–120, 40–400 (custom ranges available) GPH: 10–70, 16–160, 25–250, 80–400, 100–500, 100–600, 200–800, 100–1000 |

| Measuring Range – Gas | L/min: 0.05–0.5, 0.1–1, 0.2–2, 0.25–2.5, 0.6–6, 1–4, 1–5, 1–10, 1–12 0.1–0.8, 0.1–1.5, 0.3–3 0.4–4, 0.5–8, 1–5, 1–12, 2–10, 2–20, 3–15, 3–30, 4–20, 5–25, 6–30 m³/h: 0.05–0.25, 0.04–0.4 |

| Scale Type | Metric scale (custom calibration available) |

| Regulator / Valve Option | With regulating valve / Without regulating valve |

| O-ring Material | Silicone rubber / Fluorocarbon rubber (FKM) / Nitrile rubber (NBR) |

| Connector Material | ABS / PP / PVC / Brass / Chrome-plated brass / Stainless steel |

| Installation Orientation | Vertical |

| Customization | Flow range, scale calibration, valve option, sealing material, connector material |

Flow Meter OEM/ODM

Customization & Instrava Support

Instrava offers customizable variable area rotameter solutions to meet specific application requirements, including flow range selection, connection types, float materials, and scale calibration.

As a partner focused on industrial measurement and control instruments, Instrava provides reliable flow measurement solutions supported by trust, communication, and long-term collaboration, helping customers improve process efficiency and operational reliability.

Related Product Recommendations

A variable area rotameter is used for visual measurement of liquid or gas flow in pipelines and process systems. It is commonly applied where simple, reliable, and cost-effective flow indication is required without external power or electronic output.

Yes. Acrylic flow meters can be designed and calibrated for liquid or gas measurement. The flow range, float design, and scale are selected according to the medium to ensure stable and accurate indication.

The recommended operating flow should fall within 30–70% of the full scale of the rotameter. Selecting a proper flow range improves reading stability and measurement repeatability while avoiding float saturation at high flow.

Acrylic rotameters can handle mildly corrosive media by selecting compatible body materials, connectors, and sealing O-rings such as PP, PVC, or fluorocarbon rubber. Material compatibility should always be verified for specific chemical applications.

No. Acrylic variable area flow meters operate on a purely mechanical principle and do not require electrical power, wiring, or signal output. Flow is indicated directly by the float position on the scale.

Variable area rotameters should be installed vertically with upward flow. Proper vertical alignment and stable mounting are essential to ensure correct float movement and accurate flow indication.

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.