- Por Instrava

- 01/10/2026

- 0 Comentario

Types of Magnetic Level Gauge for Industrial Applications | Engineering Guide

Magnetic level gauge technology is often discussed as a single category, but in real industrial practice, magnetic level gauges are available in multiple configurations, each optimized for specific process conditions, installation constraints, and safety requirements.

Understanding the different types of magnetic level gauge is essential for engineers responsible for liquid level indication in oil & gas, LNG/LPG storage, chemical processing, and other demanding environments. Selecting the wrong configuration can lead to reduced accuracy, mechanical stress, or long-term reliability issues.

This article provides a structured overview of the main magnetic level gauge types used in industry and explains how each type supports different application scenarios.

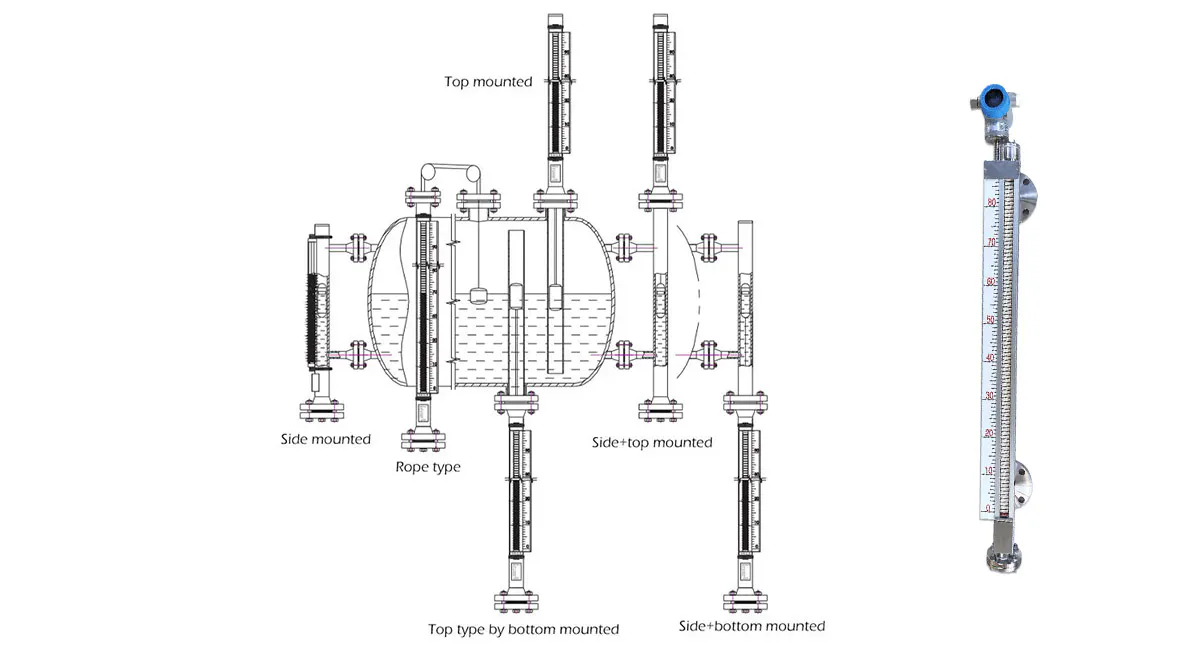

Standard Side-Mounted Magnetic Level Gauge

The most common configuration is the side-mounted magnetic level gauge. It is installed externally on a vessel using upper and lower process connections, allowing the chamber to mirror the liquid level inside the tank.

Typical characteristics

External bypass chamber

Suitable for medium to large vessels

Continuous visual level indication

Easy inspection and maintenance

Common applications

Oil and gas separators

Chemical storage tanks

Utility water systems

This type is widely used because it provides a good balance between mechanical simplicity and measurement stability.

Top-Mounted Magnetic Level Gauge

Top-mounted magnetic level gauges are installed from the top nozzle of a vessel, with the float suspended inside the chamber or guided pipe.

When top-mounted designs are preferred

Limited side nozzles available

High-pressure vertical vessels

Applications with internal obstructions

Because installation access differs from side-mounted designs, careful attention must be paid to float guidance and vertical alignment.

Magnetic Level Gauge with High-Pressure Design

In high-pressure service, magnetic level gauges are engineered with reinforced chambers, pressure-rated flanges, and high-strength materials.

Typical pressure conditions

LNG and LPG storage

Gas-liquid separation vessels

Pressurized hydrocarbon tanks

High-pressure magnetic level gauges are often selected as a mechanical reference in systems where electronic instruments may be exposed to signal instability.

Cryogenic Magnetic Level Gauge

Cryogenic magnetic level gauges are designed specifically for extremely low-temperature applications such as LNG or liquid nitrogen storage.

Key design features

Cryogenic-compatible materials

Special float magnet selection

Thermal isolation between process and indicator

At cryogenic temperatures, magnetic stability and material contraction must be carefully considered to maintain reliable indication.

Magnetic Level Gauge with Remote Signal Output

While magnetic level gauges are inherently mechanical, many industrial installations require remote level signals for control systems or monitoring platforms.

This configuration integrates:

Reed switch chains

Magnetostrictive sensors

Analog or digital signal outputs

In these systems, the magnetic level gauge provides local visual confirmation, while the remote signal supports automation and alarm functions.

Instrava supports measurement architectures where mechanical indication and remote monitoring coexist, ensuring both operational visibility and system integration.

Magnetic Level Gauge for Corrosive or Hazardous Media

For corrosive or toxic fluids, magnetic level gauges are constructed using specialized materials such as stainless steel alloys or lined chambers.

Key considerations

Material compatibility with process media

Seal integrity under temperature cycling

Long-term corrosion resistance

In hazardous environments, magnetic level gauges are often chosen to minimize direct operator exposure to the process fluid.

Comparison of Magnetic Level Gauge Types

| Gauge Type | Typical Application | Key Advantage |

|---|---|---|

| Side-mounted | Storage tanks | Easy installation |

| Top-mounted | Vertical vessels | No side nozzles needed |

| High-pressure | LPG/LNG systems | Mechanical strength |

| Cryogenic | LNG tanks | Low-temperature stability |

| With remote output | Automated plants | Local + remote indication |

| Resistente a la corrosión | Chemical processing | Media compatibility |

Selection Challenges Across Different Types

Although magnetic level gauges are robust, selection errors still occur. Common challenges include:

Incorrect float design for fluid density

Underestimating temperature effects on magnet performance

Choosing inappropriate chamber materials

Overlooking installation orientation constraints

Addressing these factors early in the design phase helps ensure reliable long-term operation.

Why Multiple Magnetic Level Gauge Types Are Still Relevant

Modern industrial plants rarely rely on a single measurement technology. Different magnetic level gauge types allow engineers to adapt the same core principle to a wide range of conditions without sacrificing reliability.

Rather than competing with electronic level instruments, magnetic level gauges often serve as:

Independent visual references

Redundant safety indicators

Stable benchmarks during system upsets

Instrava approaches level measurement with a focus on process conditions, long-term reliability, and engineering collaboration, ensuring that the selected magnetic level gauge type aligns with real operational needs.

Conclusion

Magnetic level gauge technology is not one-size-fits-all. Side-mounted, top-mounted, high-pressure, cryogenic, and signal-integrated designs each address specific industrial challenges.

By understanding the different types of magnetic level gauge and their intended applications, engineers can improve safety, reduce maintenance risk, and ensure consistent level indication across a wide range of industrial processes.