- By Instrava

- 01/10/2026

- 0 Comment

Integrated Gas Detection Systems for Oil & Gas and Chemical Plants

Industrial facilities in the oil & gas and chemical processing sectors face complex safety challenges due to flammable gases, toxic emissions, and oxygen-deficient atmospheres. Ensuring personnel safety and process protection requires a comprehensive gas detection strategy. By integrating fixed and portable gas detectors, facilities can achieve multi-layered protection, early warning, and compliance with safety standards.

Instrava is a trusted partner providing equipment, solutions, and services for industrial measurement and control instruments used in safety-critical and process control applications. With a focus on reliability, communication, and collaboration, Instrava helps customers monitor gas hazards while optimizing operational processes.

1. Why Integrated Gas Detection is Essential

Fixed detectors monitor high-risk areas continuously, while portable detectors protect personnel during dynamic operations such as maintenance, inspection, and confined space entry.

Benefits of an integrated system include:

Layered protection: Area-wide coverage + personal monitoring

Early detection: Fixed detectors trigger alarms before personnel are exposed

Redundancy: Portable detectors cover areas not reached by fixed units

Regulatory compliance: Meets OSHA, NFPA, and EN standards

Exemple : In chemical plants, combining fixed methane detectors near tanks and portable CO detectors for maintenance personnel ensures full coverage and reduces near-miss incidents.

2. Components of an Integrated Gas Detection System

| Component | Function | Industrial Application | Instrava Product Example |

|---|---|---|---|

| Fixed Gas Detectors | Continuous area monitoring | Storage tanks, pipelines, reactors | Instrava Fixed LEL Methane Detector |

| Portable Gas Detectors | Personal monitoring | Confined spaces, maintenance | Instrava Portable Gas Monitor |

| Control & Alarm Panels | Centralized alarm & monitoring | Facility-wide alerts | Instrava SCADA Interface |

| Data Logging & Analytics | Historical trends & predictive maintenance | Compliance & incident analysis | Instrava Data Logger System |

Aperçu : Integrating fixed and portable detectors enhances safety coverage and enables actionable insights from real-time and historical data.

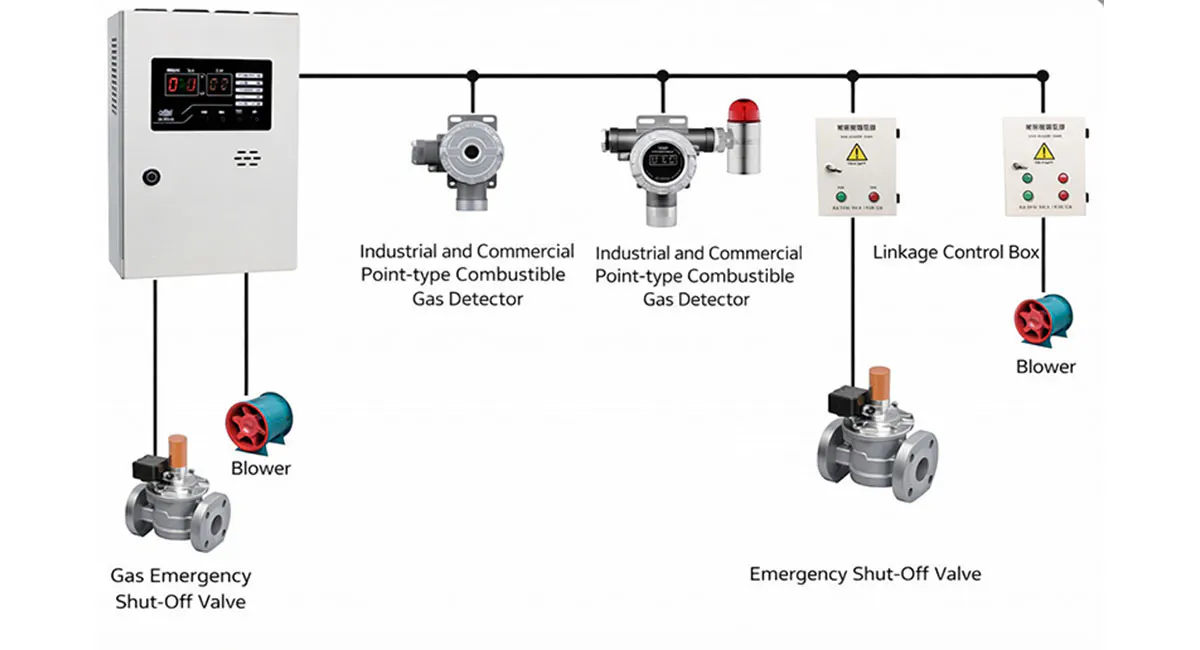

3. System Architecture and Layout

Area-Wide Monitoring (Fixed Detectors)

Monitor high-risk zones: storage tanks, reactors, vent stacks, and pipelines

Integrate alarms with SCADA or PLC systems for automated responses

Personal Monitoring (Portable Detectors)

Protect personnel during inspections, maintenance, or confined space entry

Wearable devices alert the user to dangerous gas levels in real-time

Integration Points

Centralized SCADA/PLC systems combine fixed and portable detector data

Alarm protocols trigger ventilation, emergency shutdowns, and notifications

Historical data logged for safety audits and predictive maintenance

4. Alarm Management and Response

| Alarm Type | Trigger | Recommended Action |

|---|---|---|

| Area Alarm | Fixed detector | Evacuate personnel, activate ventilation, notify control room |

| Personal Alarm | Portable detector | Immediate personal evacuation, report to supervisor |

| Combined Alarm | Fixed + Portable | Full facility shutdown, emergency response team activated |

Instrava’s integrated system allows real-time alerts and automated responses, reducing response time and minimizing risk.

5. Installation Guidelines

Placement: Fixed detectors near gas accumulation points; portable detectors with personnel

Height: Light gases (methane) → near ceiling; heavy gases (propane, CO2) → near floor

Dead Zones: Avoid unmonitored corners and maintenance areas

Alarm Visibility: Ensure audible and visual alarms reach all personnel

Example Table: Recommended Detector Placement

| Location | Gas Type | Detector Type | |

|---|---|---|---|

| Tank Farm | Methane | Fixed LEL | |

| Boiler Room | CO | Fixed Electrochemical | |

| Pipeline Corridor | Methane | Portable LEL | |

| Confined Space | CO & Methane | Portable Multi-Gas |

6. Maintenance and Calibration

| Task | Device | Frequency | Purpose |

|---|---|---|---|

| Bump Test | Fixed & Portable | Weekly / Before use | Verify sensor and alarm functionality |

| Calibration | Fixed & Portable | 6–12 months | Maintain measurement accuracy |

| Sensor Replacement | Fixed & Portable | Per manufacturer guidance | Prevent sensor drift/failure |

| Data Logging | Integrated System | Continuous | Regulatory compliance & predictive maintenance |

Best Practices:

Keep digital logs of all calibration and testing events

Cross-check readings from fixed and portable detectors

Schedule predictive maintenance based on sensor usage and environmental conditions

7. Case Study Example

Scenario: Oil & Gas processing plant with methane and CO exposure risk.

Instrava fixed detectors: Installed near tanks, vent stacks, and pipeline corridors

Instrava portable detectors: Worn by maintenance and inspection personnel

System integration: Alarms connected to SCADA for automatic ventilation and emergency response

Outcome: Early detection prevented potential leaks, improved compliance, and enhanced personnel safety

Data Point: Integrated systems using Instrava products reduced near-miss incidents by up to 80% over 3 years.

8. Advantages of Using Instrava Systems

Comprehensive industrial safety coverage

Real-time monitoring and automated alarm responses

High reliability in harsh environments

Seamless integration with SCADA and PLC systems

Long-term partnership approach with OEMs and industrial customers

Instrava serves as a trusted long-term partner for customers and OEM partners in China, helping facilities improve processes and ensure safety.

9. Conclusion

Integrated gas detection systems combining fixed and portable detectors are essential for safe operations in oil & gas and chemical plants. Instrava’s products and solutions provide reliable monitoring, automated alarms, and data-driven insights to ensure safety, compliance, and operational efficiency.