- By Instrava

- 01/10/2026

- 0 Comment

Gas Detector Controller | Integrated Industrial Safety Solutions

Industrial operations involving flammable, toxic, or oxygen-deficient gases require real-time monitoring and centralized control to maintain safety and compliance. A gas detector controller is a critical component that integrates multiple gas detection units, providing centralized alarms, data management, and process automation.

Instrava provides reliable gas detection controllers and systems that enable industrial facilities to monitor, respond, and log gas events efficiently, ensuring safety, compliance, and operational continuity.

1. The Role of Gas Detector Controllers in Industrial Safety

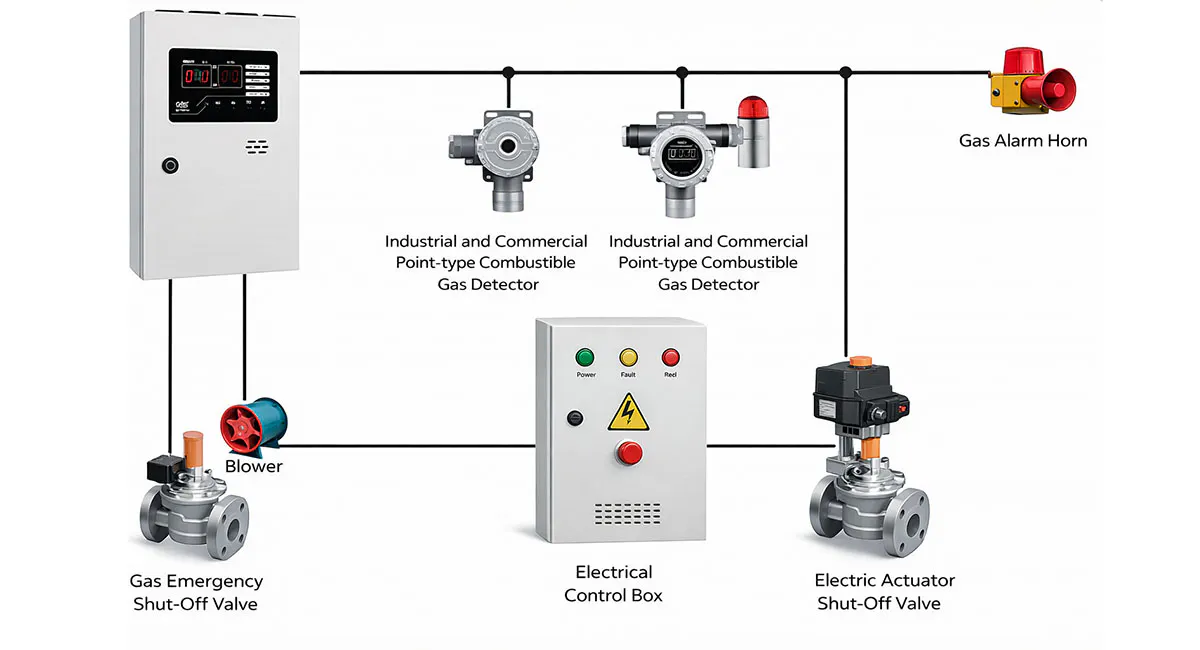

While individual gas detectors (fixed or portable) alert personnel to hazardous gas levels, a gas detector controller acts as the central command, coordinating alarms, monitoring multiple detectors, and enabling rapid response.

Key Advantages:

Centralized alarm management for multiple detection points

Real-time monitoring and visualization of gas concentrations

Integration with facility automation (SCADA/PLC)

Data logging for compliance and incident analysis

Instrava controllers are designed for industrial-grade reliability, handling inputs from multiple gas detectors across large facilities while ensuring rapid response and minimal downtime.

2. Industrial Applications

| Industry | Gas Hazard | Detector Type | Controller Role | Instrava Product Example |

|---|---|---|---|---|

| Oil & Gas | Methane, H2S | Fixed LEL / IR | Central monitoring of tank farms and pipelines | Gas Controller GC-500 |

| Chemical Processing | VOCs, toxic gases | PID / Electrochemical | Alarm aggregation and automation | GC-500 Integrated System |

| LNG/LPG Storage | Propane, butane | IR / LEL | Integrates alarms with SCADA for ventilation | GC-500 with SCADA interface |

| Pharmaceutical | Solvent vapors | PID | Personal safety & area monitoring | GC-500 with portable detector interface |

Aperçu : The controller is the hub that ensures safety-critical decisions are triggered automatically, reducing human error and response time.

3. Features of Modern Gas Detector Controllers

| Feature | Function | Benefit |

|---|---|---|

| Multi-channel Input | Connects 16–128 detectors | Monitors multiple hazardous areas from one location |

| Alarm Prioritization | Classifies alarms by gas type/severity | Enables focused emergency response |

| Data Logging & Reporting | Stores historical gas levels | Supports compliance with OSHA, NFPA, and ISO standards |

| SCADA / PLC Integration | Automatic process control | Activates ventilation, shutdown, or alerts based on gas readings |

| Remote Access | Web-based monitoring | Allows engineers to monitor multiple sites simultaneously |

Using Instrava gas detector controllers, industrial facilities can reduce downtime, improve process efficiency, and maintain high reliability even in harsh environments.

4. Installation Guidelines

Central Location: Install the controller in a secure, climate-controlled room

Wiring Considerations: Use shielded cables and follow manufacturer input/output configuration

Alarm Visibility: Ensure audible/visual alarms are visible across the facility

Redundancy: For critical sites, use redundant controllers to ensure fail-safe operation

Example Table: Typical Industrial Layout

| Area | Detector Type | Controller Function | |

|---|---|---|---|

| Tank Farm | LEL Methane | Monitor tank bases and pipelines | |

| Reactor Room | CO / VOC | Alarm aggregation & SCADA integration | |

| Pipeline Corridor | Portable & Fixed | Personal + area safety monitoring | |

| Boiler / Furnace Room | CO / H2S | Alarm & ventilation activation |

5. Alarm Management and Response

| Alarm Type | Trigger | Controller Action |

|---|---|---|

| Area Alarm | Fixed detector | Activate sirens, trigger visual alarms, send SCADA notification |

| Personal Alarm | Portable detector | Immediate personnel notification, log event |

| High-Risk Alarm | Combined fixed + portable | Shutdown processes, ventilation activation, alert emergency team |

A gas detector controller allows centralized decision-making, improving reaction time and ensuring personnel safety.

6. Maintenance and Calibration

| Task | Device | Frequency | Purpose |

|---|---|---|---|

| Controller Health Check | Gas detector controller | Monthly | Verify communication and processing |

| Detector Bump Test | Fixed & portable | Weekly / Before use | Ensure sensor response |

| Calibration | Detectors | Every 6–12 months | Maintain measurement accuracy |

| Data Audit | Controller system | Quarterly | Ensure correct logging and compliance |

Pro Tip: Controllers like Instrava gas detector controller provide real-time self-diagnostics and alert when detectors require maintenance, reducing operational risk.

7. Case Study Example

Scenario: LPG storage facility integrating multiple propane gas detectors across 10 tanks.

Instrava fixed detectors: Monitor tank bases, vent stacks, and loading areas

Instrava portable detectors: Personal safety during maintenance

gas detector controller: Centralized alarm management, SCADA integration for ventilation and emergency response

Outcome: Early detection of leaks, rapid coordinated response, zero major incidents over 3 years.

Data Point: The integration reduced response time by up to 60% compared to manual alarm monitoring.

8. Conclusion

A gas detector controller is critical for modern industrial safety, acting as the central hub for alarm management, process automation, and data logging. Instrava controllers combined with fixed and portable detectors provide reliable, integrated solutions that reduce risk, improve compliance, and enhance operational efficiency.