Instruments de mesure de niveau

Accueil » Produits » Instruments de mesure de niveau » Jauge de niveau en verre / Indicateur de niveau en verre

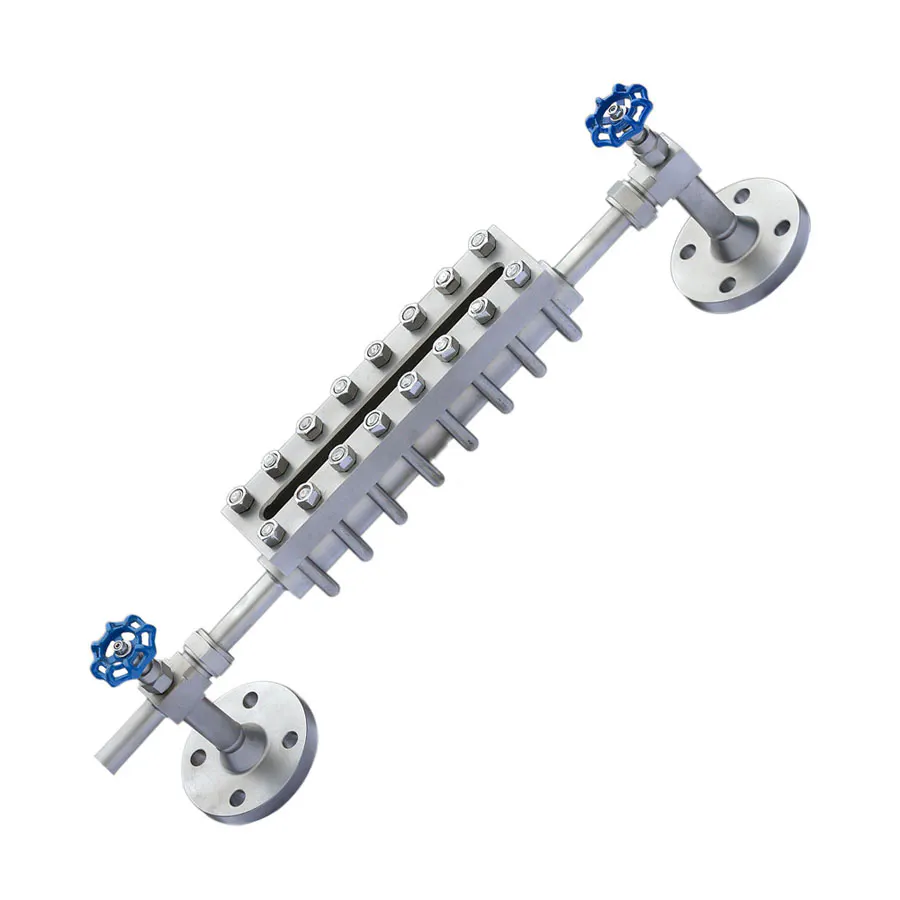

Jauge de niveau en verre / Indicateur de niveau en verre

The Glass Level Gauge is a direct-reading liquid level measuring instrument designed for continuous visual monitoring of liquid levels in tanks, vessels, and pipelines. By utilizing a transparent glass tube or flat glass panel, operators can clearly observe the actual liquid level in real time, ensuring safe and reliable process control.

✔ Direct visual indication

✔ Simple structure, no power required

✔ Suitable for harsh industrial environments

Instruments de mesure de niveau Description

Glass Level Gauge-Product Features

1️⃣ Direct Visual Liquid Level Indication

The glass level gauge provides a true, real-time visual indication of the actual liquid level inside tanks and vessels. Unlike electronic sensors, it displays the liquid position directly through the sight glass, allowing operators to immediately identify level changes, foaming, or abnormal conditions.

2️⃣ Integrated Quick Shut-Off Safety Device

Designed with a built-in quick shut-off mechanism, the gauge automatically isolates the process in the event of glass breakage or leakage. This safety feature effectively prevents vapor or liquid escape, enhancing operator safety and minimizing process risks.

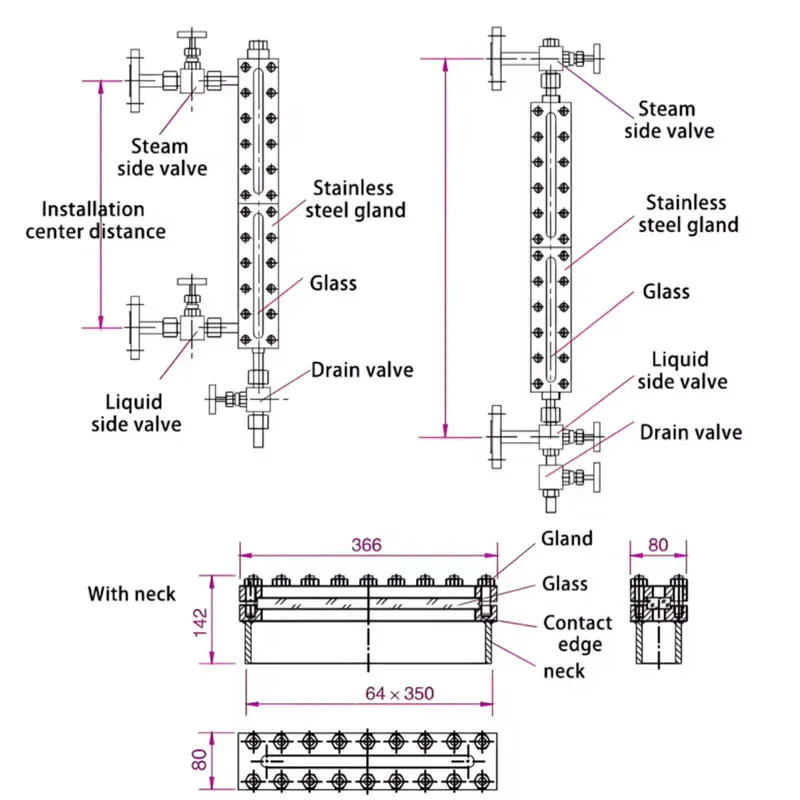

3️⃣ Robust & Practical Structural Design

The sight glass level gauge features a compact and well-engineered structure, ensuring easy installation on existing tanks or pipelines. Standard process connections allow for fast commissioning, while the modular design simplifies routine inspection and part replacement.

4️⃣ Low Maintenance & Cost-Effective Operation

With no power supply or signal components required, the glass level gauge offers long-term stable operation with minimal maintenance. The durable glass and metal components reduce downtime and spare part costs, making it an economical solution for continuous level monitoring.

Sight Glass Level Gauge-Applications / Industries

The glass plate liquid level gauge is widely used in various industrial systems where reliable and direct liquid level monitoring is required. Typical applications include:

Chemical & Petrochemical Plants

Ideal for corrosive or hazardous liquids. Provides real-time visual monitoring of reaction tanks, storage vessels, and process systems.Boilers & Steam Systems

Ensures accurate water level observation in boiler drums and steam vessels. High-temperature and pressure-resistant design with integrated safety protection.Water Treatment Systems

Enables continuous monitoring of water levels in filtration, storage, and circulation systems. Simple structure allows easy installation and maintenance.Food & Pharmaceutical Processing

Supports observation of liquid levels in clean and sanitary environments. Compatible with hygienic media and easy to sanitize.Oil & Gas Storage and Transportation

Provides safe and reliable monitoring for oil tanks, fuel storage, and pipelines. Robust design ensures stable operation under varying pressures and temperatures.

Glass Sight Glass Level Gauge-Working Principle

In general industrial systems such as water treatment units, oil tanks, and auxiliary process vessels, the glass plate liquid level gauge provides a simple and reliable method for liquid level observation. Once installed on the tank, the gauge chamber and vessel form a communicating structure, ensuring consistent liquid level indication.

The liquid level can be directly observed through the glass plate without external power supply or signal processing. The mechanical design allows stable operation under continuous service conditions, making it suitable for routine level monitoring across a wide range of industrial processes.

Installed on chemical tanks or reactors, the glass plate liquid level gauge forms a communicating vessel with the process system, enabling direct visual level observation. In case of glass rupture, the built-in safety steel ball automatically seals the flow path to reduce hazardous media leakage.

Connected to the steam and water spaces of the boiler drum, the gauge directly displays the actual boiler water level in real time. If the glass plate breaks, the automatic shut-off mechanism immediately isolates steam and water flow to ensure safe operation.

Level Gauge Sight Glass-Structure Comparison

| Type | Structural Characteristics | Visual Effect | Typical Applications |

|---|---|---|---|

| Transparent Type | Double transparent glass plates with sealed chamber; simple mechanical structure | Direct and clear observation of actual liquid level and medium | Water, oil, non-toxic liquids, general industrial tanks |

| Reflex Type | Prismatic glass surface with reflective structure; light reflection enhances contrast | Liquid appears dark, vapor area appears bright | Steam systems, boilers, high-temperature liquids |

| Mirror-Type | Flat glass with internal mirror-assisted visual enhancement | Improved readability under limited lighting conditions | Medium-pressure vessels, indoor or low-light environments |

Instruments de mesure de niveau Paramètre

| Custom | Support OEM/ODM |

| Moyen | liquide ou matériau généralement ou légèrement corrodé |

| Plage de mesure | 5m, 10m, 15m, 30m, 50m, 60m, 120m |

| Matériau du transducteur | Céramique |

| Erreur de mesure | 0.5%. 1.0% |

| Précision | ±3mm (pas de vague, surface de l'eau calme) |

| Résolution | 3~5mm ou 0.1% (prendre une grande valeur) |

| Mode d'affichage | LCD, les paramètres peuvent être réglés à l'aide des boutons du panneau. |

| Sortie du signal | 4~20mADC |

| Sortie relais | 2 groupes sont optionnels, et l'état du relais est programmable |

| Température de fonctionnement | -25~80 ℃ |

| Interface de communication | RS232, RS485/Modbus |

| Interface électrique | M20*1.5, 1/2″PT |

| Grade antidéflagrant | ExiaIICT6Ga/ExdIICT6Gb |

| Niveau de protection : | IP67 |

| Matériau de la coque : | plastique technique, alliage d'aluminium, SS304 |

| Température ambiante : | (meter) -20-60 ℃; (sensor) -20~80 ℃ |

| Humidité relative | 95% |

Instruments de mesure de niveau OEM/ODM

Sight Glass Level Gauge – OEM / ODM

Our Sight Glass Level Gauge provides direct and reliable visual monitoring of liquid levels in tanks and vessels. Designed for industrial applications, it is suitable for chemical, boiler, water treatment, and general industrial systems.

As an OEM/ODM manufacturer, we offer customizable solutions to meet specific process requirements:

Material Options: Verre borosilicaté ou quartz, cadres en acier inoxydable ou en acier au carbone, revêtements résistants à la corrosion.

Pression et température nominales : Adjustable to match your vessel’s operating conditions.

Types de connexion : Flanged, threaded, or special connections for seamless integration.

Dimensions & Lengths: Tailored gauge length, chamber size, and installation orientation.

Key Features:

Direct visual liquid level observation without electricity.

Integrated safety steel ball for automatic shut-off in case of glass breakage.

Robust and low-maintenance construction for long-term reliability.

Flexible customization to suit unique industrial processes.

Applications:

Ideal for chemical tanks, boilers, water treatment systems, food and pharmaceutical vessels, and oil & gas storage, providing safe, accurate, and real-time liquid level monitoring.

Recommandations de produits connexes

A glass level gauge, also called a sight glass level indicator, allows direct visual monitoring of liquid levels in tanks and vessels. It works on the communicating vessel principle, where liquid in the gauge matches the level in the connected container, providing accurate, real-time observation without electrical signals.

Industrial glass level gauges are available in transparent, reflex, and mirror-type configurations. Transparent gauges suit clear liquids, reflex types enhance visibility for steam or high-temperature media, and mirror-type gauges improve readability under low light or medium-pressure conditions.

Sight glass level indicators are widely used in chemical, petrochemical, boiler, water treatment, food, pharmaceutical, and oil & gas industries. They are ideal for medium- and low-pressure vessels requiring reliable visual monitoring of corrosive, high-temperature, or hazardous liquids.

The gauge is mounted via standard flanges or threaded connections. After pressure testing, valves should be opened gradually. Inspect periodically for leaks, and if the glass becomes contaminated, drain the medium safely before cleaning. Proper maintenance ensures stable performance and long service life.

Modern glass plate liquid level gauges include a safety steel ball. If the glass breaks or vapor/liquid side pressure exceeds 0.3 MPa, the steel ball automatically seals the flow path, preventing medium leakage. This feature ensures safe operation in chemical, boiler, and industrial environments.

Glass level gauges offer direct, accurate, and real-time liquid level observation without electricity. They are durable, corrosion-resistant, and low-maintenance, with built-in safety features. Suitable for chemical plants, boilers, water treatment, and general industrial vessels, they provide reliable, long-term performance.

Pourquoi choisir Instrava ?

En choisissant Instrava, vous bénéficiez d'un partenaire ayant une connaissance approfondie des applications industrielles et l'expertise nécessaire pour relever les défis opérationnels d'aujourd'hui.

Notre rôle va au-delà des produits - nous soutenons votre réussite grâce à des solutions fiables et à un engagement à long terme.

L'innovation par l'ingénierie

L'innovation chez Instrava est guidée par les exigences industrielles réelles. Nous affinons continuellement nos technologies pour répondre aux défis opérationnels en constante évolution, en garantissant des performances pratiques et fiables dans des environnements exigeants.

Personnalisation en fonction de l'application

Nous offrons une personnalisation au niveau de l'ingénierie pour répondre aux conditions spécifiques du processus. De la plage de mesure et des matériaux aux signaux de sortie et aux options d'installation, nos solutions sont configurées pour s'adapter aux applications réelles.

Une qualité et une fiabilité éprouvées

La qualité et la fiabilité sont fondamentales pour chaque produit Instrava. Fabriqués sous un contrôle de qualité strict et testés de manière approfondie, nos instruments offrent des performances précises, stables et à long terme.

Une capacité mondiale avec un soutien local

Instrava associe une expertise technique mondiale à un support local réactif, garantissant à nos partenaires une technologie alignée au niveau international et un service régional opportun.

Un portefeuille de produits complet

Notre large gamme d'instruments de mesure et de contrôle nous permet de répondre à un grand nombre de besoins industriels, en fournissant des solutions intégrées à partir d'une source unique et fiable.

Soutien technique axé sur les partenaires

Nous travaillons en étroite collaboration avec nos partenaires, de la consultation technique à l'assistance après-vente. Notre objectif est de fournir des solutions qui créent une valeur durable et soutiennent le succès opérationnel à long terme.