Instruments de mesure de niveau

Accueil » Produits » Instruments de mesure de niveau » Capteur de niveau à ultrasons

Capteur de niveau à ultrasons

The ultrasonic level gauge is a non-contact, high-reliability, and cost-effective device for accurate ultrasonic level measurement of liquids, slurries, and solids in industrial environments. Designed for easy installation and low maintenance, it offers a reliable solution for water treatment, municipal, chemical, metallurgical, and machinery manufacturing applications.

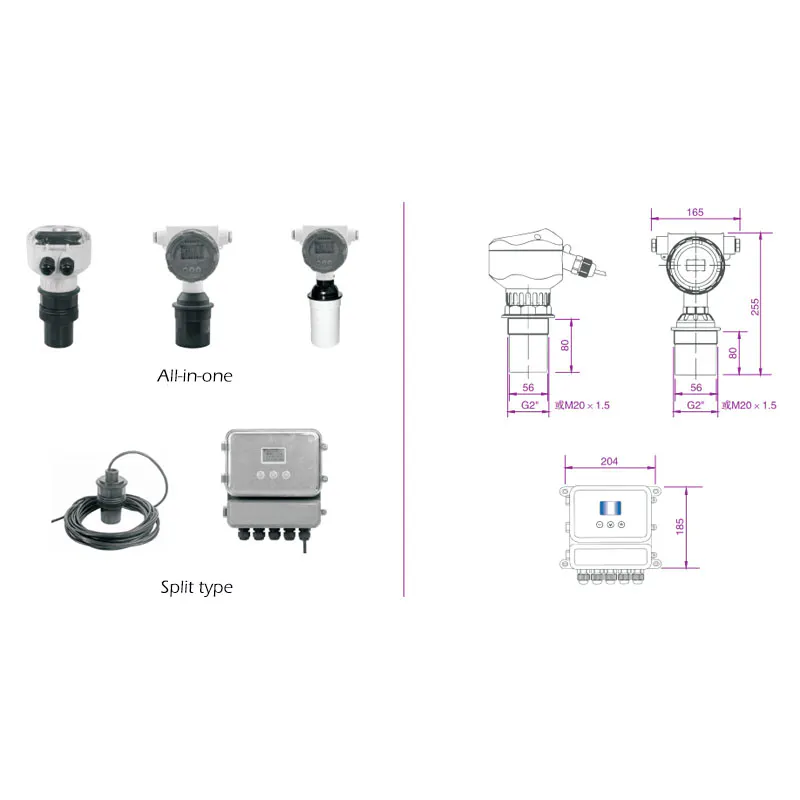

Ultrasonic level sensors are available in two types: integrated and separated. The integrated type combines the sensor and host into a single unit, providing simple and convenient installation. The separated type allows the sensor and host to be installed independently, making it ideal for storage tanks, silos, and bracket-mounted setups.

Instruments de mesure de niveau Description

Ultrasonic Level Sensor-Features

Non-contact measurement: Accurate monitoring unaffected by medium viscosity, density, or other properties, with strong anti-interference performance.

Environmentally friendly materials: Safe for the medium and prevents contamination.

Food and pharmaceutical safe: Non-toxic design suitable for sensitive applications.

Level alarm capability: Optional relay output allows real-time level alarm functionality.

User-friendly configuration: Panel button interface enables fast and convenient parameter setup.

Advanced signal processing: Microprocessor-based echo processing ensures reliable measurement in complex conditions.

Self-learning and compensation: Automatic echo identification and temperature compensation minimize drift and improve accuracy.

Rugged design: IP67 protection allows operation in most outdoor and harsh industrial environments.

Level Ultrasonic Sensor-Common Applications

Water Tanks: Ultrasonic water level sensors provide accurate, real-time monitoring for residential, commercial, and industrial tanks, preventing overflow or shortages.

Industrial Processes: Used in chemical, food & beverage, pharmaceutical, and wastewater treatment industries to maintain precise ultrasonic level measurement in tanks and vessels.

Pump Control: Can integrate with pump systems for automatic water level management in irrigation, sewage, and drainage systems.

Environmental Monitoring: Ideal for rivers, lakes, and reservoirs, enabling ultrasonic water level detection for flood forecasting and water resource management.

Hydroelectric Power Plants: Monitors reservoir levels to regulate turbine flow, ensuring safe and efficient power generation.

Aquaculture: Maintains optimal water levels in ponds, tanks, and raceways, supporting healthy growth of aquatic species.

Swimming Pools and Spas: Ensures water levels remain within safe and comfortable ranges to prevent overfilling or draining.

Ultrasonic Water Level Sensor-Working Principle

Le ultrasonic level sensor measures liquid levels using non-contact ultrasonic technology. It works in four main steps:

Ultrasonic Emission: The sensor emits ultrasonic pulses, typically in the frequency range of 20 kHz to 200 kHz.

Propagation: The pulses travel through air or other media until they encounter the liquid surface. Part of the energy reflects back while the remainder continues downward.

Reflection and Reception: The sensor’s receiver captures the reflected ultrasonic waves. The time delay between emission and reception corresponds to the travel time of the pulses.

Level Calculation: By calculating the propagation time, the sensor determines the distance from the liquid surface to the sensor, which directly indicates the liquid level.

This non-contact ultrasonic measurement ensures accurate and reliable monitoring in tanks, reservoirs, silos, and other industrial applications, making it ideal for ultrasonic water level detection and ultrasonic level measurement.

Ultrasonic Tank Level Sensor-Structure

Le ultrasonic level sensor is available in two types: integrated (one-piece) type and separated (two-piece) type, designed for flexible installation and diverse industrial applications.

Integrated Type:

The sensor and host are combined into a single unit.

Simplifies installation and wiring.

Ideal for compact tanks or vessels where space is limited.

Separated Type:

The sensor probe is installed separately from the host unit.

Suitable for large storage tanks, silos, or bracket-mounted installations.

Allows easier maintenance and flexible positioning for optimal signal reception.

Key Components:

Sensor Probe: Stainless steel or PVDF, corrosion-resistant.

Electronics Housing: IP67 protection, dustproof and waterproof.

Display/Control Module: Optional LCD/LED interface for local readings.

Connection Interface: Standard cable or M12 connector for signal transmission.

This design ensures accurate ultrasonic level measurement and reliable performance in diverse industrial environments.

Instruments de mesure de niveau Paramètre

| Measuring Medium | liquid or material that is generally or corroded |

| Plage de mesure | 5m, 10m, 15m, 30m, 50m, 60m |

| Probe Material | PTFE |

| Précision | ±3mm (pas de vague, surface de l'eau calme) |

| Résolution | 3~5mm or 0.1% (take large value> |

| Mode d'affichage | LCD, les paramètres peuvent être réglés à l'aide des boutons du panneau. |

| Sortie du signal | 4~20mADC |

| Résistance à la charge | 250Ω (when two-wire 24V power supply);500Ω (when four-wire 220VAC power supply) |

| Sortie relais | 2 groupes sont optionnels, et l'état du relais est programmable |

| Relay Contact Capacity | 250VAC 8A. 30VDC 5A |

| Température de fonctionnement | -25~80 °C |

| Rated Pressure | -0.1 ~ 1.0MPa |

| Interface de communication | RS232, RS485/Modbus |

| Alimentation électrique | Standard 24 V DC; Optional 220VAC; Battery type 3.8V 25600mAh |

| Interface électrique | M20*1.5, 1/2″NPT |

| Grade antidéflagrant | Exia II C T6 Ga/Exd IIC T6 Gb |

| Protection level | IP67 |

Non contact liquid level indicator, LCD display, with rs485 signal output

Instruments de mesure de niveau OEM/ODM

Ultrasonic Level Measurement-OEM ODM

We offer full OEM/ODM services for ultrasonic level sensors, providing flexible solutions tailored to your industrial needs. Our customization options include:

Measurement Range & Accuracy: Adjust the detection range and precision to match your specific application.

Output Signals: 4–20 mA, HART, or Modbus interfaces for seamless integration.

Material & Housing: Stainless steel, PVDF, and IP67-rated protection for harsh environments.

Installation Options: Integrated (one-piece) or separated (two-piece) types, with flange, bracket, or threaded mounting.

Display & Control Modules: Optional LCD/LED indicators for local monitoring.

Our experienced factory ensures high-quality production, fast prototyping, and reliable delivery, enabling you to implement customized ultrasonic level measurement solutions efficiently.

Recommandations de produits connexes

An ultrasonic level sensor is a non-contact device that measures the distance to the surface of liquids or solids using high-frequency sound waves. The sensor emits ultrasonic pulses, which reflect off the material surface; the time-of-flight determines the level.

Manufacturer advantages:

No physical contact, reducing corrosion and contamination

Suitable for open tanks, silos, and reservoirs

Fournit continuous, real-time level monitoring

Ultrasonic level sensors are ideal for non-corrosive, moderate-temperature applications:

Oil & Gas: Monitoring storage tanks for fuel, diesel, and light crude oil

Chemical: Measuring water-based or non-corrosive chemicals

Pharmaceutical: Tank and hopper level measurement for hygienic solutions

Manufacturer perspective: Proper sensor selection ensures accurate measurement without risking chemical contamination or sensor degradation.

| eature | Capteur de niveau à ultrasons | Jauge de niveau radar | Indicateur de niveau magnétique |

|---|---|---|---|

| Précision | ±5–10 mm | ±1–3 mm | ±1–5 mm |

| Contact | Non-contact | Non-contact | Float inside chamber |

| Pressure tolerance | Low | High | High |

| Temperature tolerance | Moderate | High | High |

| Maintenance | Moyen | Low | Very low |

Manufacturer note: Ultrasonic sensors are best for open-air or low-pressure tanks, while radar and magnetic gauges are preferred for high-pressure, high-temperature, or corrosive fluids.

Yes. Ultrasonic sensors are commonly used in:

Water & Wastewater: Reservoirs, clarifiers, and sludge tanks

HVAC Systems: Chilled water and hot water storage tanks

Environmental Monitoring: Rainwater and stormwater level measurement

Manufacturer tip: Ensure proper tank geometry and echo-free mounting for accurate measurement.

Energy & Power: Cooling water tanks, fuel level monitoring

Automotive: Fluid level measurement in manufacturing tanks

Marine & Shipping: Ballast water, fresh water, and bilge monitoring

Mining & Environmental: Tailings, slurry, and sediment measurement

Manufacturer insight: Ultrasonic sensors provide cost-effective, non-contact measurement for applications with moderate process conditions.

Medium characteristics: Density, foam, vapor, turbulence

Tank geometry: Shape, size, and internal obstructions

Temperature & pressure: Typically <80°C and <1 MPa for standard models

Output: 4–20 mA, HART, Modbus

Installation: Avoid obstructions in the beam path; consider mounting height

Proper selection ensures stable, reliable, and maintenance-efficient level measurement.

Pourquoi choisir Instrava ?

En choisissant Instrava, vous bénéficiez d'un partenaire ayant une connaissance approfondie des applications industrielles et l'expertise nécessaire pour relever les défis opérationnels d'aujourd'hui.

Notre rôle va au-delà des produits - nous soutenons votre réussite grâce à des solutions fiables et à un engagement à long terme.

L'innovation par l'ingénierie

L'innovation chez Instrava est guidée par les exigences industrielles réelles. Nous affinons continuellement nos technologies pour répondre aux défis opérationnels en constante évolution, en garantissant des performances pratiques et fiables dans des environnements exigeants.

Personnalisation en fonction de l'application

Nous offrons une personnalisation au niveau de l'ingénierie pour répondre aux conditions spécifiques du processus. De la plage de mesure et des matériaux aux signaux de sortie et aux options d'installation, nos solutions sont configurées pour s'adapter aux applications réelles.

Une qualité et une fiabilité éprouvées

La qualité et la fiabilité sont fondamentales pour chaque produit Instrava. Fabriqués sous un contrôle de qualité strict et testés de manière approfondie, nos instruments offrent des performances précises, stables et à long terme.

Une capacité mondiale avec un soutien local

Instrava associe une expertise technique mondiale à un support local réactif, garantissant à nos partenaires une technologie alignée au niveau international et un service régional opportun.

Un portefeuille de produits complet

Notre large gamme d'instruments de mesure et de contrôle nous permet de répondre à un grand nombre de besoins industriels, en fournissant des solutions intégrées à partir d'une source unique et fiable.

Soutien technique axé sur les partenaires

Nous travaillons en étroite collaboration avec nos partenaires, de la consultation technique à l'assistance après-vente. Notre objectif est de fournir des solutions qui créent une valeur durable et soutiennent le succès opérationnel à long terme.