Level Measuring Instruments

Home » Level Measuring Instruments

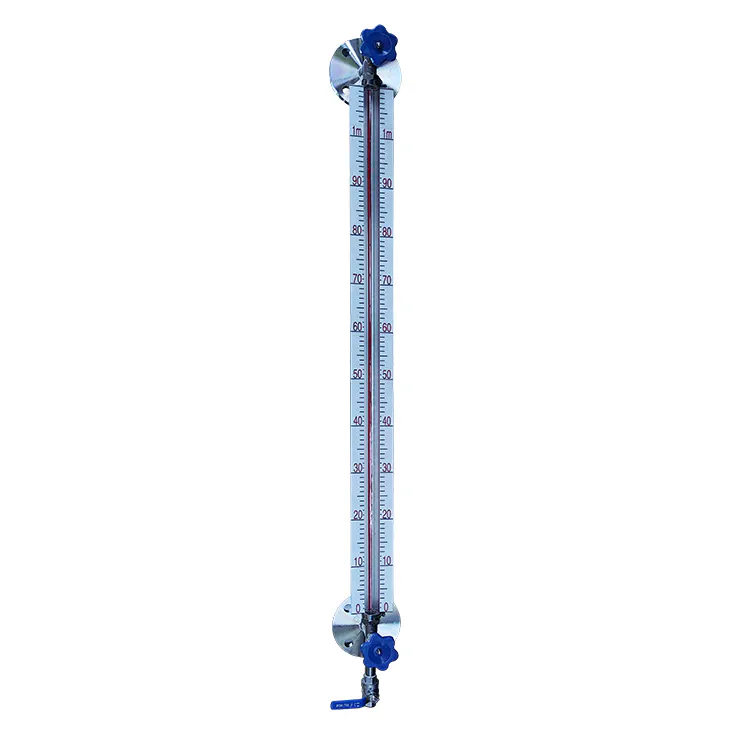

Measurement range: 440-2200mm

Working pressure: 1.6MPa

- Safety Critical, Low Maintenance, CE

Measurement range: 300-2000mm

Working pressure: 10MPa

- Explosion Proof, High Pressure, Industrial Grade

Measurement range: 300-670mm

Working pressure: 21.511.5-MPa

- High Temperature, High Pressure, Industrial Grade

Measurement range: 440-2200mm

Working pressure: 22MPa

- Intrinsically Safe, High Temperature, High Pressure

Measurement range: 0-6m

Working pressure: ≤32MPa

- Intrinsically Safe, Industrial Grade, Long Term Stability

Measurement range: 0-20m

Working pressure: 16MPa

- Intrinsically Safe, Low Maintenance, CE

Download liquid level meter product information EN document

Level Measurement Knowledge Hub

This page provides a structured, engineering-focused overview of industrial level measurement. It is designed to support selection, application, and system design decisions rather than basic definitions. The content reflects real process conditions and long-term operational considerations.

1. Role of Level Measurement in Industrial Systems

Level measurement is a core component of process safety, control, and inventory management. In industrial environments, level information is rarely used in isolation. It supports interlocks, alarms, batch control, and material balance. The value of a level measurement device lies not only in accuracy, but in its stability, availability, and compatibility with the overall system.

Key objectives of level measurement systems include:

Preventing overfill or dry-run conditions

Maintaining process continuity and balance

Supporting safety-related functions

Providing reliable data for automation and optimization

2. Level Gauge, Level Sensor, and Level Transmitter – System Roles

Different level measurement devices serve different roles within a system:

Level gauges provide local visual indication for operators and maintenance personnel.

Level sensors convert level changes into electrical signals for control or alarm purposes.

Level transmitters deliver standardized outputs for integration with PLC, DCS, or SCADA systems.

In many applications, these devices are used together to provide redundancy, cross-verification, and operational flexibility. Selecting the right combination is often more important than choosing a single device type.

3. Key Selection Factors for Level Measurement Devices

Effective selection starts from process conditions rather than product type. Critical factors include:

Process medium properties such as density, viscosity, corrosiveness, foaming, or solids content

Operating pressure and temperature ranges

Vessel geometry and installation constraints

Required response time and signal stability

Maintenance access and lifecycle cost considerations

A level sensor that performs well in laboratory conditions may behave very differently in a real industrial environment. Selection should prioritize reliability under actual operating conditions.

4. Application-Oriented Measurement Challenges

4.1 High-Pressure and High-Temperature Vessels

In pressurized or high-temperature applications, mechanical integrity and sealing reliability become critical. Level gauges and level sensors must maintain performance without material degradation or signal drift over time.

4.2 Media with Foaming, Coating, or Solids

Foaming liquids, sticky media, or suspended solids can interfere with level measurement. Certain measurement principles tolerate these conditions better than others. Proper matching of technology and wetted materials reduces false readings and maintenance frequency.

4.3 Dynamic Process Conditions

Rapid filling, emptying, or agitation introduces turbulence that can distort level readings. Installation position and damping characteristics of the level sensor play a key role in achieving stable measurement.

5. Installation and System Integration Considerations

Installation quality directly affects level measurement performance. Important aspects include:

Nozzle location relative to inlets, outlets, and agitators

Vertical alignment and mounting rigidity

Electrical grounding and signal shielding

Integration with control systems and alarm logic

A well-designed installation often improves measurement reliability more than incremental improvements in sensor accuracy.

6. Reliability, Redundancy, and Safety Strategy

In safety-related applications, level measurement is rarely dependent on a single device. Common strategies include:

Combining local level gauges with independent level sensors

Using separate devices for control and high-level alarms

Implementing fault detection and signal validation in the control system

These approaches reduce the risk of undetected failure and support safe operation under abnormal conditions.

7. Maintenance, Calibration, and Lifecycle Cost

Lifecycle cost is influenced by more than purchase price. Key contributors include:

Calibration frequency and accessibility

Cleaning or inspection requirements

Spare parts availability

Downtime during maintenance activities

Selecting level measurement devices with low maintenance demands can significantly reduce total cost of ownership over the system lifecycle.

8. Industry-Specific Level Measurement Practices

Level measurement practices vary by industry:

Process industries prioritize robustness and long-term stability

Water and wastewater applications emphasize corrosion resistance and ease of maintenance

Oil and gas applications often require compliance with hazardous area standards

Understanding industry-specific expectations helps align measurement strategy with operational reality.

9. Common System-Level Mistakes in Level Measurement

Frequent issues encountered in level measurement projects include:

Selecting devices based solely on accuracy specifications

Ignoring installation constraints during design

Underestimating the impact of process variation

Relying on a single measurement point for safety-critical functions

Avoiding these mistakes requires a system-level perspective rather than a product-centric approach.

10. Building a Robust Level Measurement Strategy

A robust level measurement strategy considers device selection, installation, integration, and maintenance as a unified system. By focusing on long-term performance and operational context, level gauges and level sensors can deliver consistent value throughout the life of the plant.

This knowledge structure is intended to support informed decision-making and continuous improvement in industrial level measurement systems.

Level Gauge-FAQ

How should a level gauge be selected for long-term industrial operation?

Level gauge selection should be based on operating conditions such as pressure, temperature, medium properties, and installation constraints. For continuous operation, stability and resistance to process variation are often more important than laboratory accuracy. In many industrial systems, the level gauge also functions as a level sensor for control or alarm purposes, so signal reliability over time is a critical factor.

What factors most commonly affect level measurement accuracy in real applications?

In real process environments, accuracy is influenced by medium density changes, temperature fluctuation, mechanical vibration, and buildup on wetted parts. Unlike ideal test conditions, industrial level gauges must tolerate these factors while maintaining repeatable output. Selecting a level sensor designed for the actual process conditions significantly reduces long-term deviation.

How does installation position influence level gauge performance?

Installation position directly affects measurement reliability. Nozzle orientation, vessel geometry, and proximity to inlets or agitators can introduce turbulence or false readings. Proper positioning ensures that the level gauge or level sensor reflects true liquid level rather than localized disturbances within the vessel.

When should a local level gauge be combined with a level transmitter or level sensor?

Local level gauges provide visual confirmation and are often used for routine inspection, while level sensors or transmitters enable remote monitoring and control. In many applications, combining both improves operational safety by offering redundancy and cross-verification between visual indication and electronic signal output.

How do process media properties impact level gauge and level sensor selection?

Media properties such as viscosity, corrosiveness, foaming tendency, and presence of solids play a major role in selection. Certain level gauges perform well with clean liquids but may struggle with sticky or abrasive media. Matching the level sensor design and wetted materials to the medium helps prevent measurement drift and mechanical failure.

What are common challenges when using level gauges in high-pressure or high-temperature vessels?

High-pressure and high-temperature conditions place additional stress on seals, materials, and measurement components. Under these conditions, a level gauge must maintain mechanical integrity while the level sensor remains stable and responsive. Selecting designs rated for the full operating envelope is essential for safe and reliable measurement.

How is reliability evaluated for level gauges used in safety-related applications?

Reliability is evaluated based on long-term stability, resistance to process upset, and consistency of output under varying conditions. In safety-related applications, level gauges are often used alongside independent level sensors to provide layered protection and reduce the risk of undetected level deviation.

What maintenance considerations affect the lifecycle cost of a level gauge?

Maintenance frequency, accessibility, and recalibration requirements directly impact lifecycle cost. A level gauge that requires frequent cleaning or adjustment may appear cost-effective initially but increases downtime and maintenance effort. Choosing a level sensor with low maintenance requirements improves overall system efficiency.

Can one level gauge design cover multiple tank or vessel configurations?

While some level gauges offer flexible mounting options, optimal performance is typically achieved when the design is matched to the vessel type. Vertical tanks, horizontal vessels, and pressurized containers each impose different measurement challenges, making application-specific selection an important consideration.

How do level gauges and level sensors support process control and optimization?

Beyond indication, level gauges and level sensors provide critical input for inventory management, process control, and alarm systems. Stable and accurate level data helps operators maintain process balance, prevent overfill or dry-run conditions, and improve overall operational efficiency.

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.