- By Instrava

- 02/04/2026

- 0 Comment

Optical vs Electrochemical Dissolved Oxygen Sensor: Which Technology Is Right for Your Application?

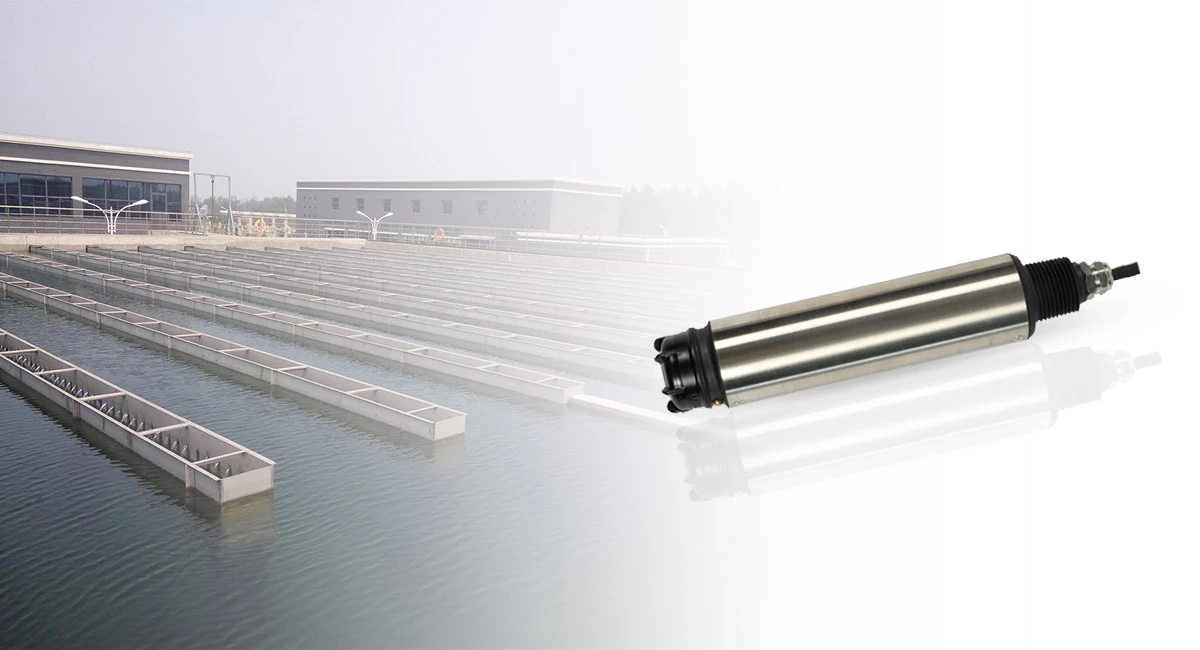

Dissolved oxygen (DO) measurement is a critical parameter in water treatment, aquaculture, environmental monitoring, and industrial processes. Among available technologies, optical dissolved oxygen sensors and electrochemical dissolved oxygen sensors are the two most widely used options.

Although both measure the same parameter, their working principles, maintenance requirements, and long-term performance differ significantly. Understanding these differences helps engineers and operators choose the right sensor for their application.

Working Principles Explained

How Optical Dissolved Oxygen Sensors Work

Optical dissolved oxygen sensors use fluorescence quenching technology. A luminescent layer is excited by light, and the presence of oxygen shortens the fluorescence lifetime. The sensor calculates dissolved oxygen concentration based on this change.

Key characteristics of optical sensors:

No membrane

No electrolyte

No oxygen consumption

Measurement independent of flow velocity

This fundamentally non-consumptive principle makes optical sensors stable over long periods.

How Electrochemical Dissolved Oxygen Sensors Work

Electrochemical sensors typically use galvanic or polarographic principles. Oxygen diffuses through a membrane and reacts at electrodes inside the sensor, generating a current proportional to oxygen concentration.

Key characteristics of electrochemical sensors:

Requires membrane and electrolyte

Oxygen is consumed during measurement

Accuracy affected by flow conditions

Regular maintenance required

This technology has been widely used for decades but comes with inherent limitations.

Side-by-Side Comparison

| Feature | Optical DO Sensor | Electrochemical DO Sensor |

|---|---|---|

| Measurement principle | Fluorescence quenching | Electrochemical reaction |

| Oxygen consumption | None | Yes |

| Flow dependency | No | Yes |

| Membrane required | No | Yes |

| Electrolyte required | No | Yes |

| Maintenance frequency | Very low | High |

| Long-term drift | Low | Moderate to high |

| Response speed | Fast | Moderate |

| Typical lifespan | Long | Shorter due to consumables |

This comparison highlights why optical technology is increasingly preferred for continuous and long-term monitoring applications.

Accuracy and Stability in Real Applications

Optical Sensors: Designed for Long-Term Monitoring

Because optical sensors do not consume oxygen, their readings remain stable even in low-flow or stagnant water. Annual drift is minimal, making them suitable for unattended installations such as:

Wastewater treatment basins

Remote environmental monitoring stations

Aquaculture ponds and tanks

Built-in temperature compensation further enhances measurement reliability.

Electrochemical Sensors: Sensitive but Maintenance-Heavy

Electrochemical sensors can deliver accurate measurements when properly maintained and operated under ideal flow conditions. However, membrane aging, electrolyte depletion, and electrode fouling can lead to drift and frequent recalibration.

They are often better suited for:

Laboratory use

Short-term testing

Applications with regular manual maintenance

Long-Term Stability and Sensor Drift

Long-term stability is a decisive factor when selecting a dissolved oxygen sensor for continuous monitoring.

Sensors with high drift require frequent recalibration, increasing maintenance workload and compromising data reliability.

No Data Found

As illustrated in the chart, optical dissolved oxygen sensors demonstrate significantly lower drift over a 12-month operating period.

This stability is attributed to their non-consumptive measurement principle, which eliminates electrolyte depletion and membrane aging — common issues in electrochemical sensors.

Maintenance and Total Cost of Ownership

While electrochemical dissolved oxygen sensors often have a lower initial purchase cost, they typically require:

Membrane replacement

Electrolyte refilling

Frequent recalibration

Flow control to ensure accuracy

Optical dissolved oxygen sensors eliminate most of these requirements. Over time, reduced maintenance labor, fewer spare parts, and longer service intervals significantly lower the total cost of ownership, especially in industrial and municipal applications.

Maintenance Requirements and Operational Burden

Maintenance frequency directly affects operational cost, labor allocation, and system uptime.

Comparing the maintenance demands of optical and electrochemical dissolved oxygen sensors reveals a clear difference in long-term operational efficiency.

No Data Found

The data indicates that optical dissolved oxygen sensors typically require minimal maintenance, often limited to periodic visual inspection or cap replacement.

In contrast, electrochemical sensors rely on membranes and electrolytes that must be replaced regularly, increasing both maintenance frequency and downtime.

Application-Based Recommendations

Choose Optical Dissolved Oxygen Sensors When:

Continuous monitoring is required

Maintenance access is limited

Flow conditions are unstable or low

Long-term data reliability is critical

Typical industries include water treatment, aquaculture, industrial process monitoring, and environmental observation.

Choose Electrochemical Dissolved Oxygen Sensors When:

Budget constraints dominate initial selection

Measurements are short-term or laboratory-based

Regular manual maintenance is acceptable

otal Cost of Ownership (TCO) Over Time

Initial purchase price alone does not reflect the true economic impact of a dissolved oxygen sensor.

A total cost of ownership (TCO) analysis provides a more realistic comparison by accounting for maintenance, downtime, and operational risks.

No Data Found

Although electrochemical dissolved oxygen sensors may appear cost-effective at the initial stage, their cumulative operational expenses often exceed those of optical sensors over a multi-year lifecycle.

Optical dissolved oxygen sensors therefore offer a more predictable and sustainable solution for long-term monitoring applications.

Technology Trend: Why Optical Sensors Are Gaining Market Share

Advances in fluorescence materials, digital signal processing, and sensor packaging have made optical dissolved oxygen sensors more robust and affordable. As automation and remote monitoring become standard, the demand for maintenance-free and stable sensors continues to grow.

Many system integrators and end users are now transitioning from electrochemical to optical solutions to improve reliability and reduce operating costs.

Instrava focuses on optical dissolved oxygen sensor solutions designed for industrial-grade durability, long-term stability, and seamless system integration.

Conclusion

Both optical and electrochemical dissolved oxygen sensors have their place, but they serve different priorities. Electrochemical sensors remain useful for controlled, short-term measurements, while optical dissolved oxygen sensors excel in long-term, low-maintenance, and flow-independent monitoring.

Choosing the right technology depends on application requirements, maintenance capabilities, and long-term operational goals.