Oval Gear Flow Meter: Why It Still Dominates High-Viscosity Flow Measurement in Modern Automation

The Quiet Persistence of Oval Gear Flow Meters In an era where smart sensors, digital twins, and AI-driven instrumentation dominate...

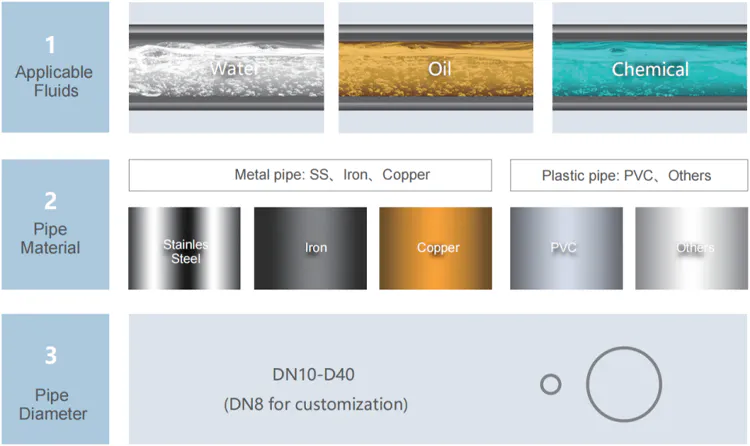

Designed for Small Diameter Pipeline Flow Monitoring

In many industrial and commercial systems, flow measurement on small diameter pipelines presents unique challenges:

Limited installation space

No allowance for pipe cutting or process shutdown

Requirement for quick installation and minimal maintenance

Corrosive or humid operating environments

The integrated clamp-on ultrasonic flowmeter is specifically developed to address these scenarios, providing reliable flow monitoring for DN10–DN40 pipelines without disturbing the process.

Flow Meter Description

Ultrasonic Flowmeter Clamp On-Simple Installation, Stable Measurement, Zero Process Interruption

Unlike traditional inline flowmeters, this clamp-on ultrasonic flowmeter focuses on ease of deployment and operational safety:

Non-intrusive measurement – no pipe cutting, no welding, no production stoppage

Integrated compact design – small footprint, ideal for confined installations

No moving parts – no pressure loss and minimal maintenance

No electrical conductivity required – suitable for water and other non-conductive liquids

Installation can be completed by on-site personnel without specialized training, following installation videos or step-by-step diagrams.

Ultrasonic Water Flow Meter-Working Principle

The ultrasonic flowmeter clamp-on operates using the transit-time principle:

Ultrasonic signals are transmitted through the pipe wall and liquid

Signals travel with and against the flow direction

The difference in propagation time is proportional to the flow velocity

The instrument calculates volumetric flow based on pipe size and velocity

Since the sensors are mounted externally, the measurement is completely isolated from the process medium.

Ultrasonic Flow Meter-Typical Applications

Small diameter water distribution pipelines

Equipment cooling lines

Chemical dosing and auxiliary process lines

OEM equipment flow monitoring

Skid-mounted systems and compact process units

Ultrasonic Water Flow Meter-Structural Design & Reliability

Built for Harsh and Compact Environments

Integrated housing: Sensor and electronics combined for fast installation

PP glass fiber reinforced enclosure: Excellent resistance to acid and alkaline environments

No internal contact with liquid: Eliminates corrosion and fouling risks

Industrial-grade protection circuits:

Reverse polarity protection

Power surge protection

Output short-circuit and surge protection

This structure ensures stable long-term operation in demanding industrial conditions.

Flow Meter Parameter

| Item | Specification |

|---|---|

| Product type | Integrated clamp-on ultrasonic flowmeter |

| Model | UF 125 |

| Pipe size | DN10, DN15, DN20, DN25, DN32, DN40 |

| Pipe material | Metal, PVC, PP, PVDF rigid plastic |

| Measured liquid | Water and other single-phase liquids (no solids or impurities) |

| Temperature range (process) | 0 to 75 °C (no surface freezing) |

| Low velocity cutoff | 0.1 m/s (factory default) |

| Measurement accuracy | ±2% (±1% after calibration) |

| Response time | 0.5 to 60 s |

| Display | 256 × 128 LCD |

| Output signal | 4–20 mA |

| Communication | Modbus RS485 |

| Optional outputs | Pulse (OCT), relay alarm |

| Power supply | 20–28 VDC |

| Power consumption | < 1 W |

| Data storage interval | 300 ms |

| Memory backup | EEPROM, >10 years data retention |

| Enclosure protection | IP65 |

| Ambient temperature | −10 to +60 °C (no freezing) |

| Relative humidity | 35–85% RH (non-condensing) |

| Vibration resistance | 10–55 Hz, double amplitude 1.5 mm |

| Shock resistance | 100 m/s², 16 ms pulse |

| Main materials | Aluminum, industrial plastics |

| Cable length | 2 m standard (PT1000 sensor cable: 9 m) |

Instrava OEM/ODM

Instrava supports customers beyond standard products:

Pipe size and material matching guidance

Calibration support for improved accuracy

OEM integration and customized output configurations

Long-term technical support and application consulting

Instrava is a partner focused on providing equipment, solutions, and services for industrial measurement and control instruments used in safety-critical and process control applications.

Related Product Recommendations

Yes. It is specifically designed for DN10 to DN40 pipelines where inline meters are difficult to install.

No. The ultrasonic measurement principle does not require electrical conductivity.

No. Installation is external and does not require pipe cutting or production shutdown.

Yes. The PP glass fiber enclosure provides strong resistance to acidic and alkaline conditions.

No. Installation can be completed by general maintenance personnel using provided guides or videos.

No. There are no moving parts and no obstruction inside the pipe.

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.

The Quiet Persistence of Oval Gear Flow Meters In an era where smart sensors, digital twins, and AI-driven instrumentation dominate...

Portable Ultrasonic Flow Meters – Accurate Industrial Flow Measurement | Instrava Portable Ultrasonic Flow Meters Overview Portable ultrasonic flow meters...

In industrial environments where pipeline shutdown, pipe cutting, or process interruption is not feasible, non-intrusive flow measurement has become an...