Transmitter

Home » Products » Transmitters » Hydrostatic Pressure Transmitter

Hydrostatic Pressure Transmitter

he hydrostatic liquid level gauge, also known as a hydrostatic pressure transmitter or hydrostatic pressure level transmitter, is designed for precise and reliable liquid level measurement in industrial and environmental applications. This advanced hydrostatic pressure transmitter utilizes the linear relationship between liquid height, density, and hydrostatic pressure to accurately convert liquid level variations into a standard 4–20 mA DC signal.

Equipped with imported high-stability sensors and advanced temperature compensation technology, this hydrostatic liquid level gauge delivers excellent anti-interference performance, long-term reliability, and stable readings under varying environmental conditions. Ideal for monitoring water tanks, reservoirs, wells, chemical storage, and other liquid containers, it is widely recognized among hydrostatic pressure transmitter manufacturers in China and globally.

This submersible hydrostatic pressure transmitter ensures seamless integration with PLC, SCADA, and DCS systems, making it a preferred solution for digital hydrostatic pressure transmitters, water level transmitters, and high-accuracy hydrostatic level monitoring applications. Its robust design allows continuous operation in harsh environments, providing accurate liquid level data for industrial processes, flood monitoring, and environmental water management.

Transmitter Description

Hydrostatic Pressure Transmitter Features

High Anti-Interference, Stability, and Reliability: This hydrostatic liquid level gauge is designed with advanced sensors and temperature compensation technology, ensuring accurate and stable liquid level measurements even in electrically noisy environments. It is ideal for water tanks, chemical storage, and industrial applications requiring precise hydrostatic pressure monitoring.

Lightning-Proof Design: Built with robust protection against lightning and voltage surges, the hydrostatic pressure transmitter guarantees uninterrupted operation in outdoor or high-voltage environments. This feature significantly reduces maintenance costs and enhances long-term reliability.

Customizable Hydrostatic Liquid Level Gauge: Our hydrostatic pressure transmitters can be tailored to meet specific project requirements, including measurement range, output signal (4–20 mA, 0–5 V, or 0–10 V), cable length, and process connection types. OEM and ODM services are available for industrial integrators and system manufacturers.

Advanced Measurement Principle: The hydrostatic liquid level gauge accurately measures liquid level by sensing the pressure exerted by the liquid column above the sensor. The pressure is then converted into a linear 4–20 mA DC signal, providing precise, real-time data for integration with PLC, SCADA, or DCS systems.

Hydrostatic Pressure Level Transmitter Applications

The hydrostatic liquid level gauge, also known as a hydrostatic pressure transmitter or hydrostatic pressure level transmitter, is widely used for precise measurement of liquid levels and hydrostatic pressure in various industrial and environmental applications. Its robust design and high-accuracy sensors make it suitable for both corrosive and non-corrosive liquids, providing reliable monitoring in challenging environments.

Typical applications include:

Petroleum Industry: Monitoring fuel and oil tanks, storage reservoirs, and pipelines with submersible hydrostatic pressure transmitters for accurate level measurement.

Iron and Steel & Metallurgy: Measuring liquid levels in molten metal handling, water cooling systems, and chemical baths using high-accuracy hydrostatic transmitters.

Chemical Industry: Level monitoring of acid, alkali, and other reactive chemicals in open containers with corrosion-resistant hydrostatic pressure transmitters.

Light Industry: Ensuring precise liquid level measurement in beverage, food, and pharmaceutical processes with liquid level hydrostatic transmitters.

Thermal Power Plants: Boiler water level monitoring and condensate tanks using digital hydrostatic pressure transmitters for real-time data integration.

Sewage Treatment & Environmental Monitoring: Measuring water levels in open channels, reservoirs, and treatment tanks with water level transmitters for reliable process control.

Our hydrostatic liquid level gauges and hydrostatic pressure transmitters manufactured in China provide customizable solutions for industrial integrators, including options for different measurement ranges, output signals, and mounting configurations. With high anti-interference and stability, these transmitters are an ideal choice for applications requiring long-term reliability and precise liquid level monitoring.

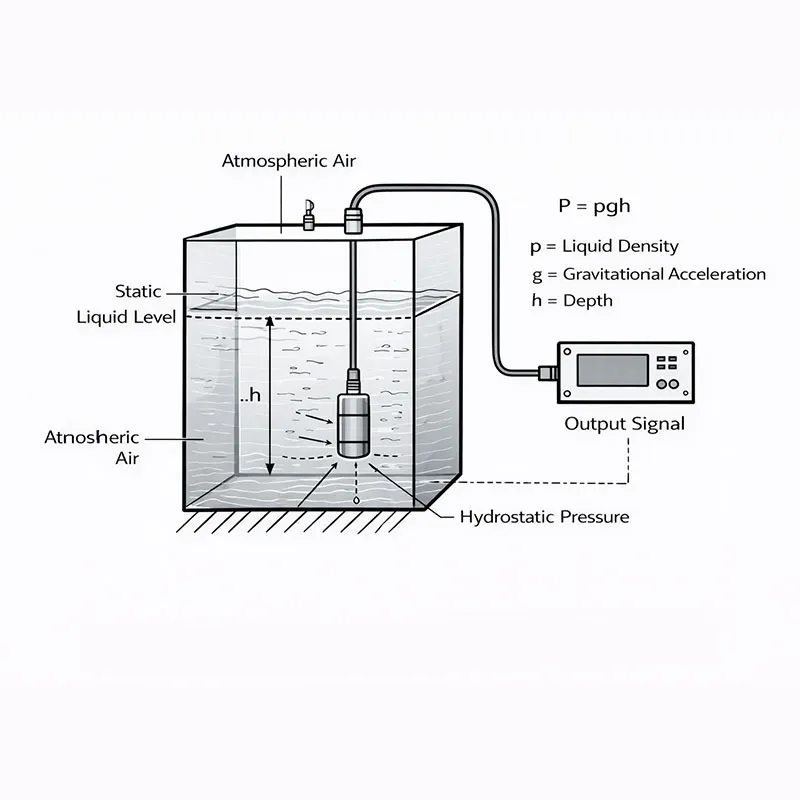

Hydrostatic Pressure Transmitter Working Principle

The hydrostatic pressure transmitter, also known as a hydrostatic liquid level gauge or hydrostatic pressure level transmitter, measures liquid level and hydrostatic pressure by leveraging the fundamental principle that the pressure at the bottom of a liquid column is directly proportional to its height and density.

This advanced hydrostatic pressure transmitter typically consists of a high-stability sensor or probe placed at the bottom of the tank or container. The sensor detects the hydrostatic pressure exerted by the liquid above it and converts this pressure into a precise electrical signal, usually a standard 4–20 mA DC output. This allows accurate, real-time liquid level readings for monitoring and control applications.

Key advantages of this measurement principle include:

High Accuracy: Provides precise liquid level measurement even in corrosive or challenging environments.

Reliability and Stability: Continuous monitoring with minimal drift, suitable for long-term industrial and environmental applications.

Integration: Can be easily connected with PLC, SCADA, or DCS systems for real-time process control.

Versatility: Compatible with water, oil, chemicals, and other liquids, making it ideal for industrial, thermal power, sewage treatment, and petroleum applications.

Hydrostatic Pressure Level Transmitter Structure

The hydrostatic pressure transmitter, also known as a hydrostatic liquid level gauge or hydrostatic pressure level transmitter, is engineered with a robust and reliable structure to ensure accurate and stable liquid level measurement across various industrial applications.

Key Structural Components:

Diaphragm/Sensor: The core component is a high-precision piezoresistive sensor with corrosion-resistant stainless steel or Hastelloy diaphragm. This sensor accurately detects the hydrostatic pressure of the liquid column and converts it into a stable electrical signal.

Probe: A submersible probe or sensor is placed at the bottom of the tank or container, ensuring continuous and precise monitoring of liquid levels.

Housing: The transmitter is housed in a durable, IP68-rated waterproof casing, making it suitable for submerged operation in tanks, reservoirs, and open water channels.

Cable & Connector: Shielded and corrosion-resistant cables transmit the signal to the control system. Connectors and process fittings, including G1/2, NPT, and flange types, are customizable for different installation requirements.

Electronics Module: Includes temperature compensation circuitry and signal processing units to ensure accurate 4–20 mA DC or other standard output signals under varying environmental conditions.

This modular design ensures easy maintenance, long-term reliability, and compatibility with PLC, SCADA, or DCS systems. The hydrostatic pressure transmitter’s structure is suitable for measuring water, oil, chemical liquids, and other media in petroleum, chemical, thermal power, sewage treatment, and industrial applications.

Transmitter Parameter

| Measuring Range | 0~200m |

| Accuracy | 0.5 |

| Signal Output | 4~20ADC, 0~20mA |

| Loading Resistance | 0~500Ω |

| Transmitting Distance | >1000m |

| Working Voltage | 24VDC |

| Working Temperature | -50~ +80 °C |

| Environmental Temperature | -20~ +60 °C |

| Relative Humidity | ≤85% |

| Contacting Liquid Material | Stainless steel, PP, PTFE |

| Installation Flange | DN32 (Standard flange: HG/T20593,20595-97) RF sealing face |

| Customize | |

| Electrical Connection | M20×1.5 |

| Explosion-proof Grade | Exia II CT6Ga Exd II CT6Gb |

Transmitter OEM/ODM

Hydrostatic Pressure Transmitter-OEM / ODM Customization

Our hydrostatic pressure transmitters, also known as hydrostatic liquid level gauges or hydrostatic pressure level transmitters, offer comprehensive OEM and ODM customization options to meet the diverse needs of industrial and environmental applications. As a trusted hydrostatic pressure transmitter manufacturer in China, we provide tailor-made solutions for clients worldwide.

Customization Options Include:

Measurement Range: Customizable ranges to suit specific tank sizes, liquid types, and industrial processes, from 0–1 mH₂O to 0–100 mH₂O or beyond.

Output Signal: Flexible electrical outputs, including 4–20 mA, 0–5 V, 0–10 V, or digital communication protocols, compatible with PLC, SCADA, or DCS systems.

Material Selection: Diaphragm and housing materials can be customized to handle corrosive liquids, high temperatures, or abrasive media.

Process Connections: Supports various connector types such as G1/2, NPT, and flanged fittings to match installation requirements.

Cable Length and Type: Adjustable cable lengths and corrosion-resistant shielding for submerged or harsh environments.

Calibration & Certification: Pre-calibration and quality certifications can be provided to meet project-specific standards or international regulations.

With these flexible OEM/ODM services, our hydrostatic pressure transmitters and hydrostatic liquid level gauges can be precisely adapted for applications in water treatment, petroleum, chemical, thermal power, metallurgy, and industrial process monitoring. High anti-interference, stable performance, and long-term reliability ensure these customized devices deliver accurate liquid level measurement wherever they are deployed.

A hydrostatic pressure transmitter, also known as a hydrostatic liquid level gauge or hydrostatic pressure level transmitter, measures the pressure exerted by a liquid column in a tank or container. The sensor at the bottom of the container converts this pressure into a standard electrical signal, usually 4–20 mA DC, for accurate liquid level readings. It is widely used in water treatment, petroleum, chemical, and industrial process monitoring.

Hydrostatic pressure transmitters are versatile and can measure water, oil, chemicals, and corrosive or non-corrosive liquids. With corrosion-resistant diaphragm materials like stainless steel or Hastelloy, these hydrostatic pressure level transmitters are suitable for applications in chemical storage tanks, wastewater treatment, and fuel monitoring systems.

High-accuracy hydrostatic transmitters provide measurement accuracy up to ±0.1–0.25% of the full scale. Advanced temperature compensation and high-stability sensors ensure consistent readings, even in harsh or electrically noisy environments, making them ideal for water level transmitters, submersible hydrostatic pressure transmitters, and industrial process monitoring.

Yes. Hydrostatic pressure transmitters can be fully customized in terms of measurement range, output signal (4–20 mA, 0–5 V, 0–10 V, or digital protocols), process connection type, and cable length. OEM/ODM options are available from hydrostatic pressure transmitter manufacturers, allowing integration into specific industrial, thermal power, or environmental monitoring systems.

These transmitters are widely used in petroleum, chemical, iron and steel, metallurgy, thermal power, and sewage treatment industries. Hydrostatic pressure transmitters measure liquid levels in tanks, reservoirs, and open channels, providing reliable data for process control, flood monitoring, and environmental water management.

Submersible hydrostatic pressure transmitters, also known as liquid level hydrostatic transmitters, offer several advantages:

Direct measurement at the liquid bottom for high accuracy

Stable performance in harsh or corrosive environments

Easy integration with PLC, SCADA, or DCS systems

Long-term reliability with minimal maintenance compared to float or ultrasonic level sensors

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.