Level Measuring Instruments

Home » Products » Level Measuring Instruments » Glass Level Gauge » Quartz Tube Bi-Colour Level Gauges

Quartz Tube Bi-Colour Level Gauges

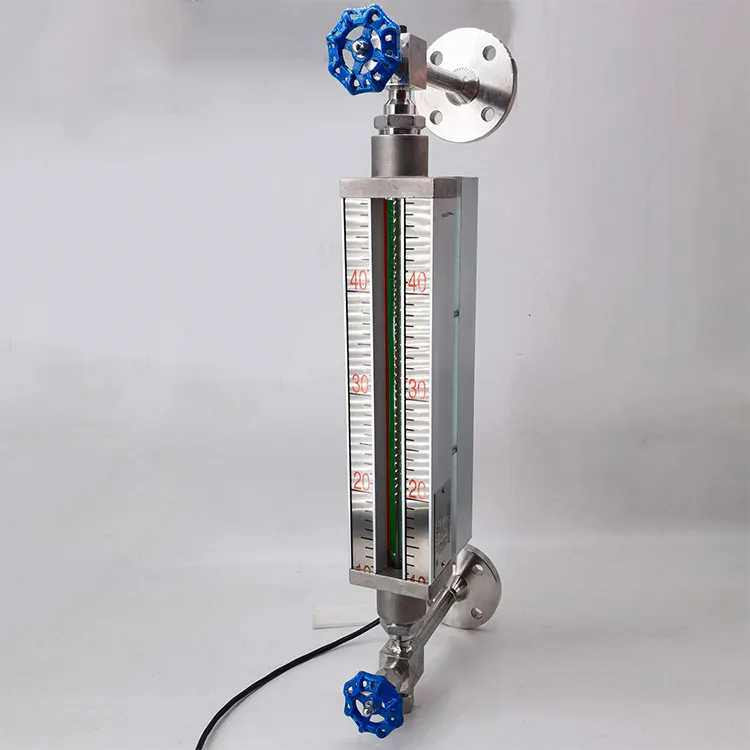

Quartz tube bi-colour level gauges are reliable and highly visible liquid level measurement instruments designed for continuous level indication in industrial process applications. By utilizing a quartz glass tube combined with a bi-colour indication system, these level gauges clearly display vapor and liquid phases, ensuring safe and accurate monitoring under high temperature and high-pressure conditions.

The bi-colour quartz tube level gauge displays red for vapor phase and green for liquid phase, allowing operators to instantly distinguish fluid states even in harsh environments. With excellent corrosion resistance, pressure resistance, and long service life, quartz tube bi-colour level gauges are widely used in petrochemical, power generation, chemical processing, and other safety-critical industries.

Level Measuring Instruments Description

Bi-Colour Quartz Glass Tube Level Gauges-Features

Clear bi-colour level indication: red vapor phase, green liquid phase

High-strength quartz glass tube with excellent thermal stability

Suitable for high pressure and high temperature applications

Multiple material options for corrosive and non-corrosive media

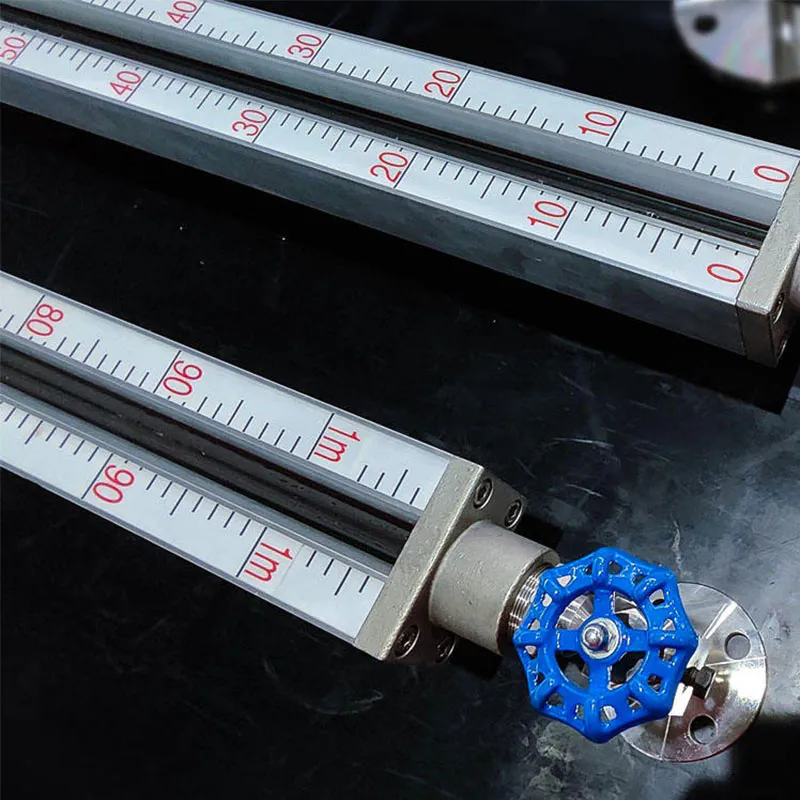

Long center-to-center distance options, customizable up to 2000 mm

Simple structure with low maintenance requirements

Optional electric heating and self-limiting temperature heating

Compatible with industrial standard flanges and connections

These features make quartz tube bi-colour level gauges an ideal solution for continuous and reliable liquid level indication.

Quartz Tube Bi-Colour Level Gauges-Applications

Quartz tube bi-colour level gauges are widely applied in:

Boilers and steam drums

Petrochemical and chemical processing plants

Power generation systems

Oil & gas production facilities

Industrial storage tanks and vessels

Process control systems requiring visual level monitoring

Safety-critical level indication applications

The high visibility and durability of bi-colour quartz tube level gauges make them suitable for both indoor and outdoor industrial environments.

quartz tube bi-colour level gauges-Working Principle

The working principle of quartz tube bi-colour level gauges is based on optical refraction and reflection. A light source projects light through the quartz glass tube:

In the liquid phase, light is refracted and reflected to appear green

In the vapor phase, light reflection changes and appears red

This optical contrast allows operators to accurately identify liquid levels in real time, even from a long distance. The quartz tube ensures stable performance under extreme temperatures and pressures.

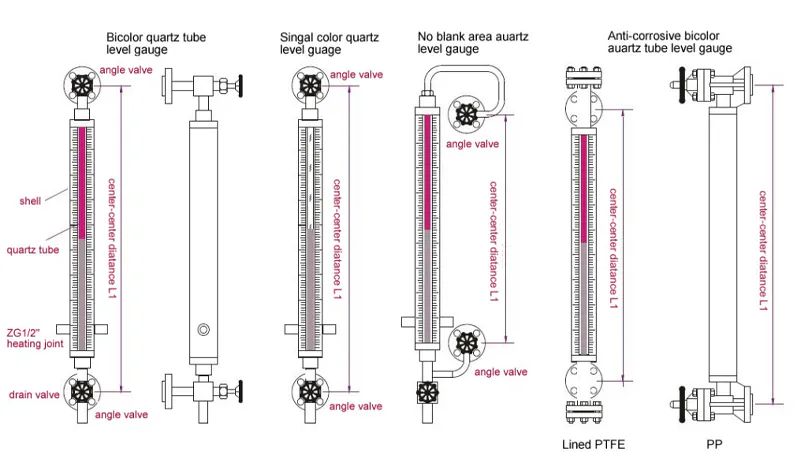

Quartz Tube Bi-Colour Level Gauge-Structure

The quartz tube bi-colour level gauge mainly consists of:

High-strength quartz glass tube

Gauge body (carbon steel or stainless steel)

Upper and lower process flanges

Drain valve and vent valve

Steel ball self-closing safety device

Optional electric or steam heating interface

The robust structure ensures safe operation and reliable sealing during long-term industrial use.

Level Measuring Instruments Parameter

| Parameter | Specification |

| Bi Color quartz tube Level Gauge-Type | INBC113 |

| Center-Center Distance | 300, 500, 800, 1100, 1400, 1700, 2000 mm (custom made) |

| Indicate Mode | Single color, bi-color (red vapor phase, green liquid) |

| Material | Carbon steel, 304, 316L, 1Cr18Ni9Ti, 0Cr18Ni9, 304 + PTFE lining |

| Nominal Pressure | PN6–PN100 (×0.1 MPa); 304 + PTFE ≤ PN40; PP ≤ 100℃ |

| Working Temperature | Carbon steel ≤ 350℃; Stainless steel ≤ 450℃; 304 + PTFE ≤ 200℃; PP ≤ 100℃ |

| Drain Valve | Drain needle valve (customizable) |

| Vent Valve | Vent needle valve (customizable) |

| Process Flange | DN20 / RF HG/T 20592-09 |

| Heat Steam Interface | ZG1/2″ male screw thread |

| Heat Steam Pressure | ≤ 1.0 MPa |

| Electric Heating | Self-limiting temperature heating (optional) |

| Steel Ball Self-Closing Pressure | ≥ 0.3 MPa |

| Power Supply | 24V DC, 36V AC |

| Environment Temperature | −50 ~ +80℃ |

Level Measuring Instruments OEM/ODM

Customization & OEM Service

Our quartz tube bi-colour level gauges can be fully customized according to specific working conditions, including:

Center-to-center distance

Material selection

Pressure and temperature ratings

Heating methods (steam or electric)

Valve types and flange standards

Instrava is a partner focused on providing equipment, solutions, and services for industrial measurement and control instruments used in safety-critical and process control applications. We are committed to delivering reliable and long-lasting solutions based on trust, communication, and collaboration, helping customers improve process efficiency and operational safety.

As a trusted long-term partner for customers and OEM partners in China, Instrava provides professional customization support, stable product quality, and responsive technical services for quartz tube bi-colour level gauges and other industrial instrumentation.

Related Product Recommendations

Quartz tube bi-colour level gauges are used for continuous visual liquid level monitoring in industrial vessels, boilers, and tanks. They provide clear red and green colour indication to distinguish vapor and liquid phases, making them suitable for high-temperature and high-pressure process control applications.

A bi-colour quartz tube level gauge works based on optical refraction and reflection. The liquid phase reflects light as green, while the vapor phase appears red, allowing operators to clearly identify liquid levels even under harsh operating conditions.

The maximum working temperature depends on the material selection. Carbon steel models can operate up to 350℃, stainless steel models up to 450℃, and PTFE-lined versions up to 200℃. This makes quartz tube bi-colour level gauges suitable for high-temperature industrial environments.

Yes. Quartz tube bi-colour level gauges support nominal pressure ratings from PN6 to PN100, making them suitable for a wide range of high-pressure industrial applications, including boilers, petrochemical systems, and power plants.

Quartz tube bi-colour level gauges can be customized in terms of center-to-center distance, materials, pressure rating, heating method, valve configuration, and flange standards to meet specific process requirements and operating conditions.

Most quartz tube bi-colour level gauges are equipped with steel ball self-closing safety devices, drain and vent valves, and optional heating systems. These features enhance operational safety and reliability in safety-critical and process control applications.

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.