Venturi Flow Meter

Venturi flow meters are differential pressure flow measurement devices designed to measure liquid, gas, and steam flow with high accuracy and long-term stability. By utilizing a converging section, throat, and diverging section, the Venturi meter converts pressure energy into velocity energy, generating a stable differential pressure proportional to flow rate.

Instrava Venturi flow meters are engineered for harsh industrial environments where reliability, low maintenance, and minimal pressure loss are critical. With no moving parts and a robust one-piece or welded construction, Venturi meters provide consistent performance over long service life, even in high-pressure, high-temperature, or dirty process conditions.

Flow Meter Description

Venturi Flowmeter Features

High measurement accuracy and repeatability

Low permanent pressure loss

Suitable for liquids, gases, and steam

No moving parts, minimal maintenance

Stable performance under high pressure and temperature

Long service life

Wide range of pipe sizes available

Suitable for harsh industrial environments

These advantages make the venturi flow meter an ideal solution for critical industrial flow measurement applications.

Venturi Tube Flow Meter Applications

Venturi flow meters are widely used in industries where stable flow measurement and low energy loss are required:

Power generation (steam, feedwater, condensate)

Oil & gas (process gas, liquid hydrocarbons)

Chemical and petrochemical processing

Water supply and wastewater treatment

Metallurgy and mining

Pulp & paper industry

Compressed air and industrial gas systems

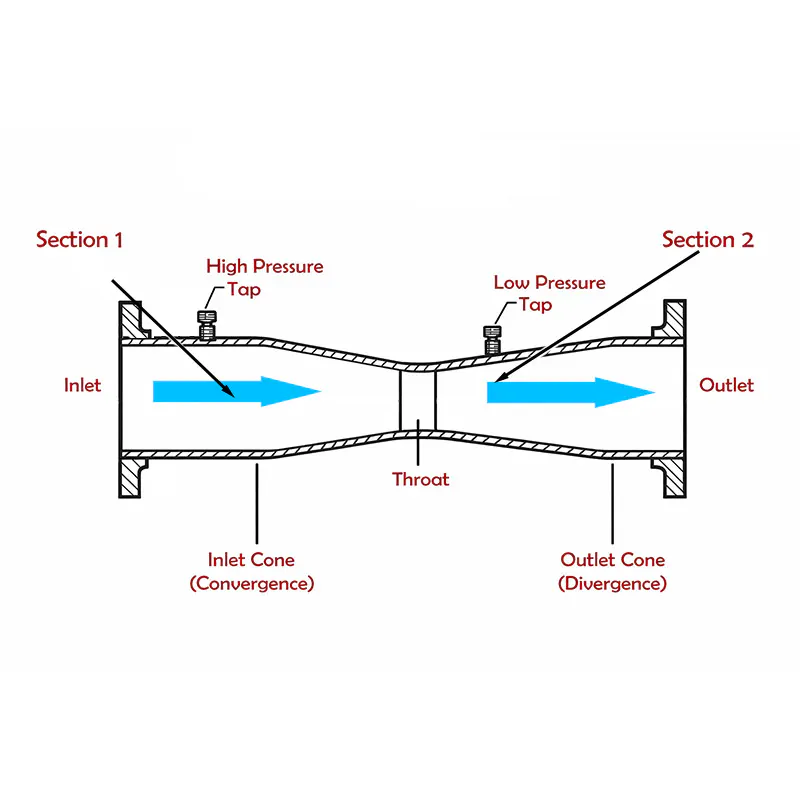

Venturi Flow Meter Working Principle

The Venturi flow meter operates based on Bernoulli’s principle. As the fluid flows through the converging section, velocity increases and static pressure decreases. The pressure difference between the inlet section and the throat is measured and used to calculate the volumetric or mass flow rate.

Because the pressure recovery in the diverging section is high, the Venturi meter produces significantly less permanent pressure loss than traditional differential pressure flow devices.

Venturi Flowmeters Structure & Design

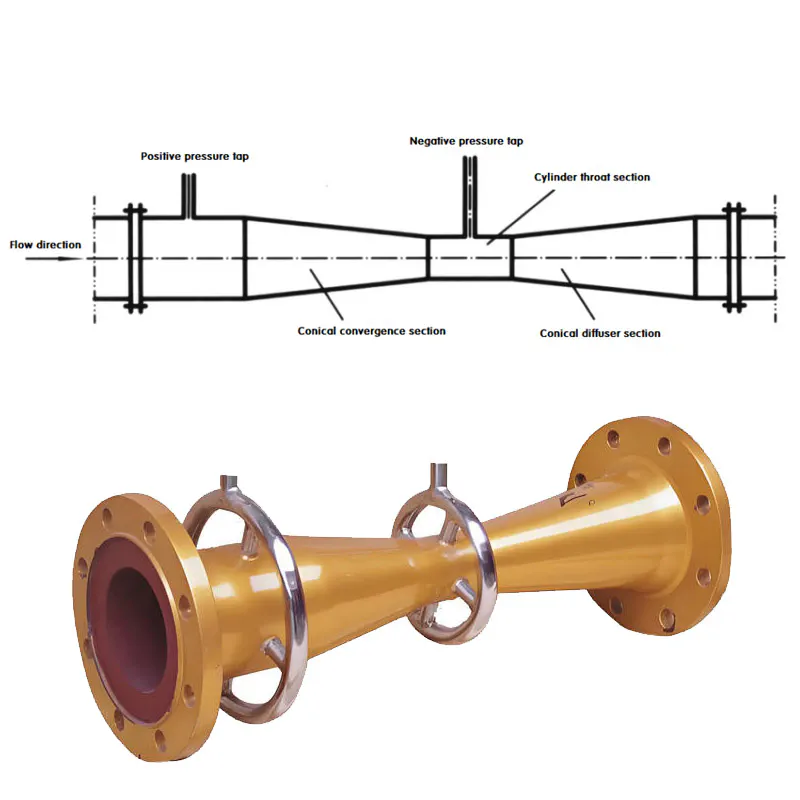

A standard Venturi flow meter consists of:

Inlet (converging section) – accelerates the fluid

Throat – produces a stable low-pressure zone

Outlet (diffuser section) – recovers pressure efficiently

Pressure tapping ports – connect to differential pressure transmitter

The rigid structure ensures excellent resistance to vibration, erosion, and process pressure fluctuations, making it suitable for long-term industrial operation.

Flow Meter Parameter

| Parameter | Specification |

|---|---|

| Nominal Diameter | DN15 – DN1200 (Sizes above DN1200 available by negotiated order / customization) |

| Nominal Pressure | ≤ 42 MPa |

| Measurement Accuracy | ±0.5% ~ ±1.5% |

| Installation Method | Flanged connection, welded connection (customized options available) |

| Pressure Tapping Method | Corner pressure tapping (ring chamber or separate drilling), flange tapping, span tapping, or other customized configurations |

| Straight Pipe Requirement | Upstream: 5–10D Downstream: 2–5D |

Flow Meter OEM/ODM

Customization & OEM Service

Venturi flow meters can be customized according to specific application requirements, including:

Pipe size and pressure rating

Material selection

Connection type

Pressure tapping configuration

Special designs for high-temperature or corrosive media

Instrava is a partner focused on providing equipment, solutions, and services for industrial measurement and control instruments used in safety-critical and process control applications. We are committed to providing reliable and long-lasting solutions based on trust, communication, and collaboration, helping customers improve process efficiency and measurement accuracy.

As a trusted long-term partner for customers and OEM partners in China, Instrava provides professional OEM and customization services for venturi flow meters and industrial flow measurement solutions.

Related Product Recommendations

Yes. Venturi flow meters are well-suited for high-pressure systems due to their robust structure and absence of moving parts. With proper material selection and pressure rating design, they can operate reliably at pressures up to tens of MPa, making them ideal for power, oil & gas, and chemical processes.

For large-diameter pipelines, Venturi flow meters offer stable measurement, low permanent pressure loss, and long service life. Compared with orifice plates, Venturi meters reduce energy loss significantly, which is especially important in DN300 and above applications.

Venturi flow meters are widely used for steam measurement because they tolerate high temperature and pressure while maintaining stable differential pressure signals. Their smooth internal profile minimizes erosion and ensures long-term accuracy in saturated and superheated steam applications.

Venturi flow meters generate lower permanent pressure loss, are less sensitive to wear, and offer better long-term stability. In high-pressure, high-temperature, or dirty process conditions, Venturi meters require less maintenance and deliver more consistent performance than orifice plates.

Yes. Proper upstream and downstream straight pipe lengths help ensure stable flow profiles and accurate measurement. However, Venturi flow meters generally require shorter straight pipe lengths than many other differential pressure devices, making them suitable for compact installations.

Venturi flow meters perform reliably under fluctuating flow and load conditions due to their stable pressure recovery design. This makes them suitable for applications such as boiler feedwater, steam distribution, and industrial process control systems with variable operating conditions.

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.