Vortex Flowmeter

The vortex flow meter is a precision instrument designed for measuring the volume and mass flow of liquids, gases, and steam based on the Kármán vortex principle. Utilizing advanced differential algorithms along with isolation measurement, shielding, and wave filtering technologies, vortex flowmeters provide high accuracy while maintaining strong immunity to vibration and noise.

Our LUGB series vortex flow meters feature unique sensor packaging technology, ensuring long-term reliability and stability even in harsh industrial environments. Upon receipt, carefully inspect your vortex flow sensor for visible damage. As a high-precision measuring instrument, it should be handled with care. Remove all protective plugs and caps for thorough inspection, and if any items are damaged or missing, contact us immediately.

Before installation, confirm that the vortex flow meter model meets your specific application requirements, whether it is for measuring water, steam, gas, or other industrial fluids. Our industrial vortex flowmeters are suitable for a wide range of applications, including chemical, petrochemical, HVAC, water treatment, and energy management systems.

Flow Meter Description

Vortex Flowmeter-Features

No Moving Parts: The vortex flowmeter features a simple and robust design with no moving components, ensuring long-term stability, reduced maintenance, and easy installation in industrial pipelines.

Pulse Signal Output: The vortex flow sensor outputs a pulse signal whose frequency is linearly proportional to the actual flow rate of liquids, gases, or steam. Zero drift is minimized, providing highly stable performance. Available in multiple structural forms, including inline and insertion types.

High Accuracy: Provides precise flow measurement, with typical accuracy of ±1.0% for liquids and ±1.5% for gases, suitable for industrial vortex flow meter applications requiring reliable monitoring.

Wide Measurement Range: Covers a broad flow range, with Reynolds number from 2×10⁴ to 7×10⁶, achieving a ratio up to 1:20, making it ideal for diverse steam and liquid vortex flowmeter applications.

Low Pressure Loss: Compared with orifice meters, the vortex flowmeter reduces pressure loss by 25–50%, offering energy-saving operation for industrial fluid systems.

Flexible Installation: Can be installed horizontally, vertically, or at various angles, allowing adaptation to different process pipeline configurations without compromising accuracy.

Anti-Interference and Anti-Vibration: Equipped with advanced anti-interference circuits and a vibration-resistant sensor head, the vortex flow sensor maintains stable performance even in challenging environments.

Non-Linearity Correction: Integrated software automatically corrects the instrument coefficient’s non-linearity, enhancing measurement precision across the full flow range.

EEPROM Data Protection: Cumulative flow data is safeguarded against power interruptions using EEPROM, with data protection lasting over 10 years, ensuring reliable long-term monitoring for industrial vortex flowmeters.

Vortex Flow Meter-Applications

The vortex flowmeter is widely used across various industries for accurate measurement of liquids, gases, and steam. In chemical and petrochemical plants, it ensures precise monitoring of process fluids, supporting safety and efficiency in critical operations. For steam and gas pipelines, vortex flow sensors provide reliable flow measurement under high temperature and pressure conditions.

In HVAC systems and energy management, industrial vortex flow meters help optimize energy usage by accurately tracking airflow and steam consumption. In water and wastewater treatment plants, they monitor the flow of water, chemicals, and sludge, ensuring process control and regulatory compliance. The food and beverage industry relies on vortex flowmeters for sanitary measurement of liquids and gases, supporting quality control and production efficiency.

Additionally, power generation facilities use vortex flow sensors to measure steam and cooling water flow, improving energy efficiency and operational reliability. With versatility across these diverse applications, vortex flow meters are an ideal choice for industries requiring precise, stable, and low-maintenance flow measurement solutions.

Vortex Flowmeters-Measuring Principle

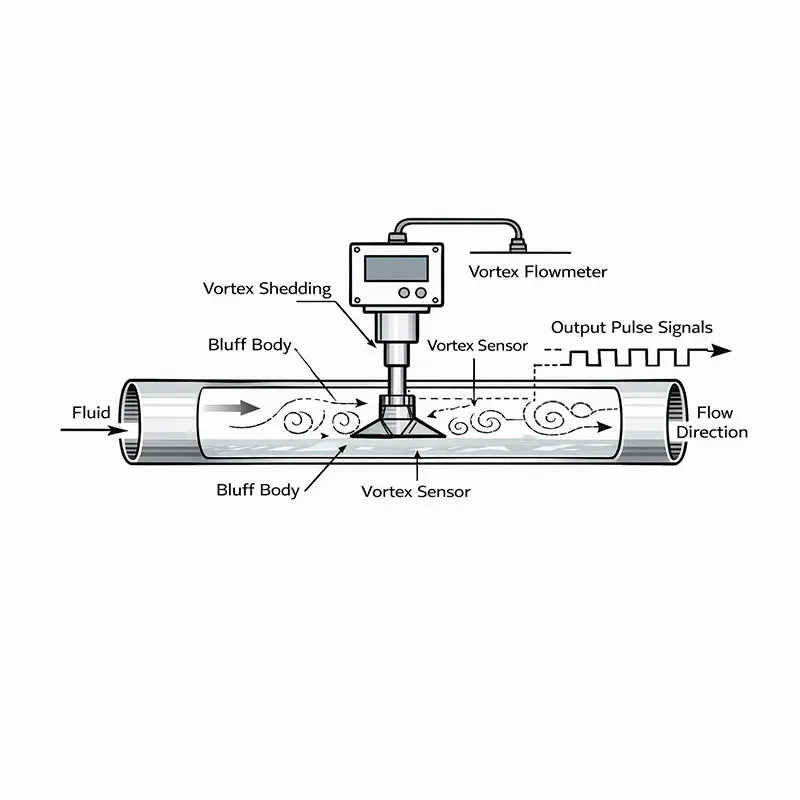

The vortex flowmeter operates based on the Kármán vortex principle, which establishes a direct relationship between vortex shedding and fluid flow. A bluff body, usually a triangular prism, is inserted into the pipeline, creating alternating vortices downstream. The vortex shedding frequency is directly proportional to the flow velocity of steam, gases, and low-viscosity liquids. The industrial vortex flow sensor detects these vortices, and the electronic signal is processed to calculate the fluid velocity and convert it into volume or mass flow rate.

This principle enables vortex flow meters and steam vortex flowmeters to deliver high-precision, reliable, and low-maintenance flow measurement across a wide range of industrial applications. Ideal for chemical, petrochemical, water treatment, HVAC, and power generation systems, these vortex flow sensors ensure accurate monitoring under various process conditions, including high temperatures, pressures, and challenging environments.

Vortex Flowmeter-Structure

The vortex flowmeter consists of a robust flow sensor body made from stainless steel, carbon steel, or specialized alloys, ensuring durability in various industrial environments. A bluff body (triangular prism) is inserted into the flow path to generate alternating vortices for accurate flow measurement. The vortex flow sensor module detects the frequency of these vortices, while the transmitter converts the signal into digital or analog outputs for monitoring and control systems.

Installation options include flanged type for direct pipeline integration and flange-clamp type for easy maintenance or replacement, making the industrial vortex flow meter versatile for different process configurations. Both inline and remote installation designs are available to meet the requirements of diverse industrial applications such as steam, gas, and liquid flow measurement.

Flow Meter Parameter

| Parameter | Specification |

|---|---|

| Measuring Medium | Liquid, gas, saturated steam, superheated steam |

| Medium Flow Rate | Liquid: 0.5–7 m/s, Gas: 4–40 m/s, Steam: 7–70 m/s |

| Accuracy Level | Liquid ±1.0%, Gas ±1.5%, Insert type ±2.5% |

| Possible Range of Measurement | Reynolds number: 5×10³ – 7×10⁸ |

| Normal Measurement Range | Reynolds number: 2×10⁴ – 7×10⁶ |

| Nominal Diameter | DN15–DN300 (pipeline/flange type), DN150–DN2000 (insert type or customized) |

| Medium Temperature | Standard: -40~80°C, Medium: -40~250°C, High Temperature: -40~350°C |

| Nominal Pressure | 1.0–6.3 MPa (customizable >6.3 MPa) |

| Installation Method | Flange type, insert type, clamp type |

| Output Signal | Voltage pulse: Low ≤1V, High ≥6V; 2-wire 4–20 mA (with RS485, HART); Pulse frequency 0.1–3000 Hz |

| Power Supply | 3-wire pulse output: 12V/24VDC optional; 2-wire system: 24VDC |

| Local Display Type | 3.6V lithium 7.5AH battery, life > 2 years |

| Load Resistance | 500Ω (when powered by 24VDC) |

| Electrical Interface | M20×1.5, 1/2″ NPT |

| Body Material | SS304, SS316L (customizable) |

| Head Material | Cast aluminum housing, stainless steel housing (customizable) |

| Environmental Conditions | Temperature -20~+60°C, Relative Humidity 5%–90% |

| Protection Level | IP65 |

| Explosion-proof Grade | Exd IIB T4 Gb, Exia IIB T4 Ga |

Flow Meter OEM/ODM

Vortex Flow Meter – OEM / ODM

Our vortex flowmeters can be fully customized to meet the specific requirements of industrial applications. As a leading vortex flow meter OEM/ODM manufacturer, we provide flexible solutions for liquids, gases, and steam measurement across diverse industries, including chemical, petrochemical, HVAC, water treatment, food & beverage, and power generation.

We offer tailored industrial vortex flow sensor designs, including:

Custom sensor and transmitter configurations for specific flow ranges and media.

Special materials for corrosive, high-temperature, or high-pressure environments.

Choice of installation types: flange, flange-clamp, or insertion type.

Output customization: 4–20mA, pulse signal, RS485, HART, or other industrial communication protocols.

Calibration and adjustment according to client-specific process requirements.

Private labeling and branding for distribution and industrial projects.

By choosing our OEM/ODM vortex flowmeters, you gain access to high-precision, low-maintenance, and reliable flow measurement instruments, backed by professional engineering support and long-term technical service. Our solutions ensure optimized process control, enhanced efficiency, and consistent quality in all your industrial applications.

Related Product Recommendations

Our industrial vortex flow meters accurately measure liquids, gases, saturated steam, and superheated steam. They are ideal for chemical, petrochemical, water treatment, and HVAC systems requiring precise vortex mass flow sensor readings.

The vortex flow sensor provides ±1.0% accuracy for liquids, ±1.5% for gases, and ±2.5% for insert-type sensors. These high-precision vortex flowmeters ensure stable, repeatable flow measurement in demanding industrial applications.

Yes, vortex flowmeters support horizontal, vertical, and angled installation. Available in flanged, flange-clamp, and insertion types, they adapt to diverse pipeline configurations while maintaining accurate steam vortex flowmeter performance.

Our vortex flow sensors provide pulse signals, 4–20mA analog output, RS485, and HART protocols. Pulse frequencies range from 0.1–3000 Hz, enabling seamless integration with industrial control systems and vortex flow meter monitoring platforms.

Equipped with vibration-resistant sensor heads, anti-interference circuits, and durable housings (SS304, SS316L, or aluminum), industrial vortex flowmeters maintain accurate measurements under high temperature, pressure, or corrosive conditions.

Yes, our OEM/ODM vortex flow meters can be tailored with custom sensor/transmitter designs, materials for corrosive or high-temperature fluids, calibration for specific flow ranges, and private labeling. This ensures every vortex mass flow sensor meets precise industrial requirements.

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.