Передатчик

Главная » Продукция » Передатчики » Радарный уровнемер для стабильных измерений в сложных технологических условиях

Радарный уровнемер для стабильных измерений в сложных технологических условиях

In many industrial processes, level measurement is affected by high temperature, pressure fluctuations, vapor, dust, foam, and complex tank structures. Conventional contact or ultrasonic sensors may experience unstable signals or frequent maintenance under these conditions.

The INRLT115 radar level transmitter is developed to address these challenges by using non-contact microwave technology, ensuring stable and accurate level measurement even in harsh and variable process environments.

Transmitter Description

Core Measurement Advantage of FMCW Radar Technology

In the INRLT115 radar level transmitter, the measurement core is not based on directly resolving time-of-flight, but on detecting the frequency difference (δf) between the transmitted and received radar signals.

The FMCW measurement logic follows this process:

Frequency difference → Distance → Level

Instead of relying on extremely fine time resolution, the transmitter analyzes the frequency offset generated by the propagation delay of the radar wave. This approach avoids the physical limitations associated with time-based resolution and enables more stable and precise distance calculation.

As a result, FMCW radar technology provides significant advantages in high-accuracy level measurement applications, especially in environments involving long measuring distances, high temperature, pressure fluctuations, vapor, dust, or foam.

This is the fundamental reason why FMCW radar level transmitters are widely adopted for demanding industrial level measurement tasks.

Where Radar Level Measurement Is the Right Choice

The INRLT115 radar level transmitter is particularly suitable for applications where other level technologies reach their limits:

High-temperature or high-pressure vessels

Tanks with strong vapor or dust formation

Foam-covered liquid surfaces

Large storage tanks or tall silos

Processes requiring continuous, non-contact measurement

Working Principle of Radar Level Transmitter (FMCW Technology)

The INRLT115 radar level transmitter operates based on FMCW (Frequency Modulated Continuous Wave) radar technology, which enables highly accurate non-contact level measurement.

Signal Transmission

The transmitter continuously emits a linearly frequency-modulated radar wave toward the surface of the measured medium.

This transmitted signal increases linearly in frequency over time.

Signal Reception

When the radar wave reaches the liquid or material surface, it is reflected back to the antenna as an echo signal.

The received echo carries information related to the distance between the transmitter and the material surface.

Time and Frequency Difference Generation

Because the transmitted and received signals travel different paths, a delay occurs between them. This delay generates:

Time difference (δt) between transmission and reception

Frequency difference (δf) between the transmitted and received signals

The relationships are defined as:

δt = 2R / C

δf = K · δt

Where:

R = distance between radar antenna and material surface

C = propagation speed of electromagnetic waves

K = frequency modulation slope

By combining these equations, the distance can be calculated as:

R = C · δf / (2K)

Level Calculation

Once the distance R is determined, the transmitter converts it into a level value based on the installation reference point. The calculated level is then output as a continuous standard signal proportional to the actual material level inside the tank or vessel.

This FMCW-based measurement principle ensures high accuracy and stable performance, even in applications involving high temperature, high pressure, vapor, dust, or foam.

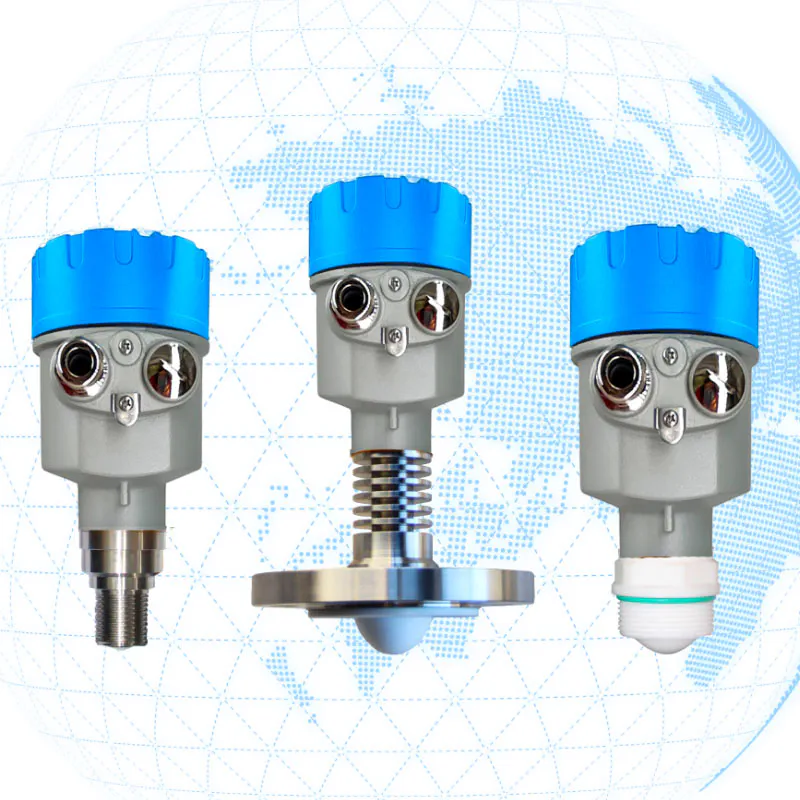

Structure & Reliability Design of INRLT115

The INRLT115 radar level transmitter is structurally designed to ensure stable and reliable measurement under complex industrial conditions.

The integrated antenna structure provides controlled beam focusing, reducing false echoes from tank walls, internals, or buildup, which directly improves signal stability. The sealed industrial housing protects internal electronics from dust, moisture, and corrosive environments, ensuring long-term operational reliability.

A rigid process connection maintains accurate beam alignment even under vibration or pressure fluctuation, preventing measurement drift. As a non-contact device with no moving or wetted parts, the INRLT115 eliminates mechanical wear and process contamination, significantly reducing maintenance requirements.

Overall, the structural design directly stabilizes the radar signal path, enabling FMCW frequency-based measurement to deliver consistent and accurate level results over time.

Transmitter Parameter

Model: INRLT115

| Артикул | Технические характеристики |

|---|---|

| Measuring Medium | Liquid |

| Диапазон измерений | 0.2 m ~ 30 m ;0.3 m ~ 150 m (depending on antenna and application) |

| Технологическое соединение | Flange ≥ DN80 ;Thread G3 A |

| Process Temperature | -40 ~ 120 °C (flange connection) -40 ~ 110 °C (thread connection) |

| Process Pressure | -0.1 ~ 1.0 MPa |

| Antenna Type | 76 mm lens antenna |

| Antenna Material | PTFE |

| Measurement Accuracy | ±2 mm |

| Launch Angle | 3° |

| Protection Class | IP67 |

| Источник питания | Two-wire system: DC 24 V Four-wire system: AC 220 V Six-wire system: DC 12–24 V |

| Сигнальный выход | Two-wire system: 4–20 mA + HART Four-wire system: 4–20 mA + HART Six-wire system: 4–20 mA + HART |

| Housing Material | Aluminum / Plastic / Stainless Steel |

Transmitter OEM/ODM

Настройка и обслуживание OEM

The INRLT115 radar level transmitter can be customized to meet specific process requirements, including:

Measurement range and antenna selection

Process connection standards

Communication protocol options

Housing and protection level

High-temperature or high-pressure design

Instrava is a partner focused on providing equipment, solutions, and services for industrial measurement and control instruments used in safety-critical and process control applications. We are committed to delivering reliable and long-lasting solutions based on trust, communication, and collaboration, helping customers improve process efficiency and measurement reliability.

As a trusted long-term partner for customers and OEM partners in China, Instrava provides professional OEM and customization services for radar level transmitters and industrial level measurement solutions.

The INRLT115 radar level transmitter uses microwave radar technology, which is minimally affected by temperature and pressure changes. Unlike contact or ultrasonic sensors, radar signals remain stable in high-temperature and high-pressure environments, ensuring reliable level measurement.

Yes. Radar signals are largely unaffected by vapor, dust, or condensation. The INRLT115 radar level transmitter is designed to maintain stable echo detection even in environments with strong vapor formation or dust clouds.

Foam can absorb or scatter acoustic signals, causing ultrasonic measurement errors. Radar signals, however, penetrate foam more effectively. This allows the INRLT115 to accurately detect the actual liquid surface beneath foam layers in many applications.

Yes. The INRLT115 features advanced signal processing algorithms that filter out false echoes caused by internal structures such as agitators, ladders, or heating coils, allowing accurate level measurement in complex tank geometries.

Radar level transmitters like the INRLT115 should be preferred when applications involve high temperature, high pressure, vapor, foam, dust, or when measurement reliability is critical under changing process conditions.

Yes. The INRLT115 radar level transmitter is suitable for both liquid and bulk solid level measurement, especially in silos or bins where dust and uneven material surfaces are present.

Почему стоит выбрать Instrava

Выбирая компанию Instrava, вы получаете партнера с глубоким пониманием промышленных применений и опытом, позволяющим решать современные производственные задачи.

Наша роль выходит за рамки продукции - мы поддерживаем ваш успех с помощью надежных решений и долгосрочных обязательств.

Инновации, управляемые инженерами

Инновации компании Instrava основаны на реальных промышленных требованиях. Мы постоянно совершенствуем наши технологии для решения возникающих производственных задач, обеспечивая практичную и надежную работу в сложных условиях.

Настройка под конкретное приложение

Мы обеспечиваем настройку на инженерном уровне для соответствия конкретным условиям процесса. От диапазона измерений и материалов до выходных сигналов и вариантов установки - наши решения настраиваются в соответствии с реальными условиями применения.

Проверенное качество и надежность

Качество и надежность являются основой каждого продукта Instrava. Изготовленные под строгим контролем качества и тщательно протестированные, наши приборы обеспечивают точную, стабильную и долговременную работу.

Глобальный потенциал с поддержкой на местах

Компания Instrava сочетает глобальный инженерный опыт с оперативной поддержкой на местах, обеспечивая нашим партнерам преимущества международных технологий и своевременного регионального обслуживания.

Широкий ассортимент продукции

Широкий ассортимент измерительных и контрольно-измерительных приборов позволяет нам удовлетворять широкий спектр промышленных потребностей, предлагая комплексные решения из одного надежного источника.

Инженерная поддержка, ориентированная на партнеров

Мы тесно сотрудничаем с нашими партнерами, начиная с технических консультаций и заканчивая послепродажным обслуживанием. Наше внимание сосредоточено на предоставлении решений, которые создают долгосрочную ценность и поддерживают долгосрочный операционный успех.