Level Measuring Instruments

Home » Products » Level Measuring Instruments » Displacer Level Gauge

Displacer Level Gauge

The Displacer Level Gauge is a high-precision liquid level measurement instrument designed for industrial applications. Using the displacement principle, it accurately measures liquid levels in tanks, vessels, and process systems. Ideal for chemical, oil & gas, and pharmaceutical industries, this gauge ensures reliable and continuous monitoring even under high temperature, high pressure, and corrosive conditions. Available in stainless steel, explosion-proof, and OEM/ODM configurations, it offers flexibility for diverse industrial environments.

Level Measuring Instruments Description

Displacer Level Gauge-Features

Robust and Reliable Design: Simple structure ensures stable performance and minimal maintenance requirements.

Safe and Isolated Indicator: The liquid level indicator is fully separated from the measured medium, providing safe and reliable operation.

Wide Pressure Range: Operates under working pressures from -0.1 to 42 MPa, suitable for most industrial processes.

Extreme Temperature Capability: Works in temperatures from -60°C to +400°C, supporting high-temperature applications.

Accurate Measurement: Includes medium density correction and temperature compensation for precise level readings.

High Viscosity Compatibility: Capable of measuring liquids with viscosity up to 500 mPa·s.

Multiple Indicator Options: Available with M2 and M3 indicators for on-site display preferences.

Flexible Signal Outputs: Supports 4-20mA two-wire signals, switch outputs, and HART protocol, ideal for remote monitoring and process integration.

Displacement Level Gauge-Applications

The Displacer Level Gauge is designed for continuous liquid level and interface measurement in demanding industrial environments. As a factory-manufactured instrument, it is engineered to deliver stable and accurate performance under high temperature, high pressure, corrosive, and hazardous conditions.

It is widely applied in the following industries:

Oil & Gas Industry

Used for level and interface measurement in crude oil tanks, separators, and storage vessels, especially suitable for high-pressure and explosion-risk areas.Chemical Processing

Ideal for measuring corrosive and toxic liquids in reactors, columns, and storage tanks, ensuring safe and reliable process control.Power Generation

Commonly installed in boilers, feedwater systems, and condensate tanks for continuous liquid level monitoring.Pharmaceutical Industry

Provides stable and hygienic level measurement in process vessels where accuracy and reliability are critical.Food & Beverage Processing

Suitable for liquid level control in production and storage tanks, supporting consistent process operation.Paper & Pulp Industry

Used for monitoring liquid levels in pulp processing and chemical dosing systems.

With a full metal structure, isolated indicator design, and multiple signal output options, the displacer level gauge is well suited for process control systems requiring long-term stability and low maintenance, making it a reliable choice for industrial liquid level measurement.

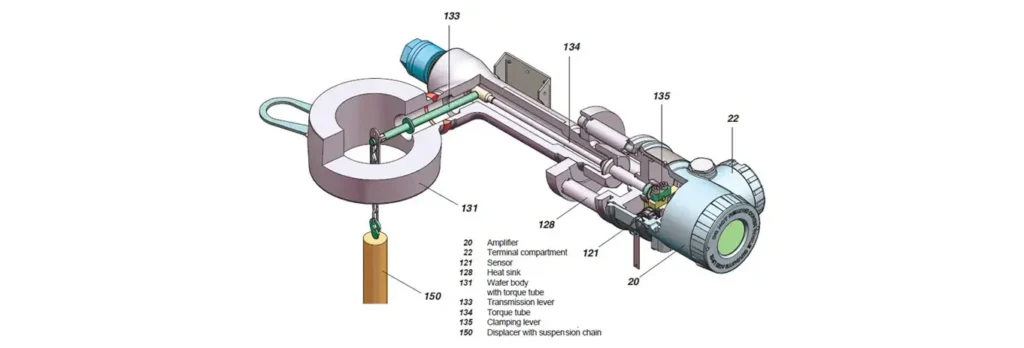

Buoyancy Level Gauge-Working Principle

The electric displacer level gauge measures liquid levels using the buoyancy principle combined with Hooke’s law. The displacer, suspended on a spring, responds to changes in liquid level: as the level rises or falls, the balance of buoyancy, gravity, and spring force shifts. This movement is transmitted through a magnetic coupling to an external indicator, providing a clear and accurate on-site reading.

Designed with a robust full-metal construction, the gauge keeps the indicator fully isolated from the measured medium, ensuring durability even in corrosive or high-temperature environments. It also offers flexible output options, including 4-20mA two-wire signals, switch outputs, and HART protocol, making it ideal for remote monitoring and seamless integration into industrial control systems.

Displacement Float Level Gauge-Indicator Function

M2 Indicator

The M2 is a square-type indicator. The vertical displacement of the displacer is transmitted through magnetic coupling and displayed on the pointer and dial, providing precise on-site liquid level readings.

M3 Explosion-Proof Indicator

The M3 is a prototype-type indicator designed for explosion-proof and intrinsically safe environments. It converts the displacer’s vertical movement into a readable value via magnetic coupling, displayed on the pointer and dial.

Explosion-Proof Rating: ExdⅡCT6Gb

Intrinsically Safe Rating: ExiallCT6Ga

The M3 indicator is ideal for hazardous areas, ensuring safe, accurate, and reliable level measurement in demanding industrial applications.

Level Measuring Instruments Parameter

| Measuring Range | 300-6000 mm (or according to user requirements) |

| Measurement Accuracy | 1.5, 2.0 |

| Buoy Material | 304, 316L, HC, Ti, etc.(Other special materials are negotiated for supply) |

| Medium Density | ≥0.45g / cm3 |

| Interface Measurement | The difference between the density of the two media is ≥0.1 g / cm3 |

| Medium Temperature | ≤80 ℃, ≤150 ℃, ≤250 ℃, ≤400 ℃ |

| Medium Pressure | standard type ≤4.0 MPa, pressure type ≤42MPa |

| Pressure Level | standard type: DN40-DN50 / PN4.0Mpa;DN80-DN100 / PN1.6MPa |

| High Pressure Type | DN40-DN50 / PN10.0MPa |

| Special Type | according to user requirements |

| Flange Standards | HG20592, DIN2501, ANSI, SH, GB (or according to user requirements) |

| Process Connection | flange DN50, G1.5 ”thread or according to user requirements |

| Output Signal | 4 ~ 20mADC (two-wire system) |

| Load Resistance | 500Ω (when 24VDC power supply) |

| Communication Output | HART, Modbus (RS485) |

| Alarm Output | upper and lower limit switch output |

| Contact Capacity | up to 400VAC 0.05A, 24VDC 0.2A |

| Working Power | 15-35VDC, 220VAC |

| Lithium Battery | 3.6V7.5HA, 220VAC |

| Ambient temperature | -20 ℃ ~ + 60 ℃ |

| Body Material | 304, 316L or user requirements |

| Display Case Material | standard type: cast aluminum, special type: 304, 316L |

| Protection Level | IP65 (IP68 negotiated supply) |

Level Measuring Instruments OEM/ODM

Displacer Level Gauge – ODM / OEM Solutions

We offer customized Displacer Level Gauges tailored to your specific process requirements. Our ODM and OEM services allow you to select:

Measurement range and accuracy to match your tank or vessel specifications

Materials including stainless steel, corrosion-resistant alloys, and high-temperature variants

Indicator types (M2, M3, explosion-proof or intrinsically safe)

Signal outputs such as 4-20mA, switch outputs, and HART protocol

With years of experience in industrial liquid level measurement, we ensure that every gauge is precisely engineered, tested, and ready for seamless integration into your process control systems.

Benefits of Our ODM/OEM Services:

Fully customizable to meet unique industrial requirements

Supports harsh and hazardous environments

Ensures reliable performance and long service life

Fast prototyping and flexible production volumes

Partner with us for professional Displacer Level Gauge customization and get a solution that perfectly fits your chemical, petroleum, power, or pharmaceutical processes.

Related Product Recommendations

The gauge operates on the buoyancy principle and Hooke’s law. The displacer’s movement in the liquid is transmitted through magnetic coupling to the external indicator, providing precise and reliable level readings.

Yes, with stainless steel or alloy construction, the gauge can operate in high-temperature liquids up to 400°C and handle corrosive chemicals, ensuring safe and durable performance in harsh industrial environments.

Yes, models with the M3 indicator are certified explosion-proof (ExdⅡCT6Gb) and intrinsically safe (ExiallCT6Ga), making them ideal for hazardous areas in chemical, oil, and gas industries.

The gauge supports 4-20mA two-wire output, switch signals, and HART protocol, allowing integration with DCS, PLC, and SCADA systems for real-time monitoring.

Yes, it measures liquids with viscosities up to 500 mPa·s, including heavy oils, syrups, and slurry, without sacrificing accuracy or responsiveness.

Yes, fully customizable solutions are available, including measurement ranges, materials, indicator types, and signal outputs, ensuring the gauge meets specific industrial process requirements.

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.