Electromagnetic Flowmeter

The working principle of an electromagnetic flowmeter is based on Faraday’s law of electromagnetic induction. The measuring tube is made of a non-magnetic alloy and internally lined with an insulating material to prevent signal interference and ensure measurement stability.

Two measuring electrodes are installed diametrically opposite on the inner wall of the flow tube, with the electrode surfaces flush with the lining. When the excitation coils generate a pulsed magnetic field perpendicular to the flow direction, a uniform magnetic flux density is formed across the measuring section.

As a conductive liquid flows through the magnetic field inside the tube, it cuts the magnetic lines of force and generates an induced electromotive force. This induced voltage is proportional to the magnetic flux density, the inner diameter of the pipe, and the average velocity of the fluid. The electrodes detect this voltage signal and transmit it to the converter through shielded cables.

The converter amplifies and processes the signal, converting it into a flow rate value. The electromagnetic flowmeter then outputs standard signals such as pulse output and analog current (4–20 mA), enabling real-time flow display, process monitoring, flow control, and system integration in industrial automation applications.

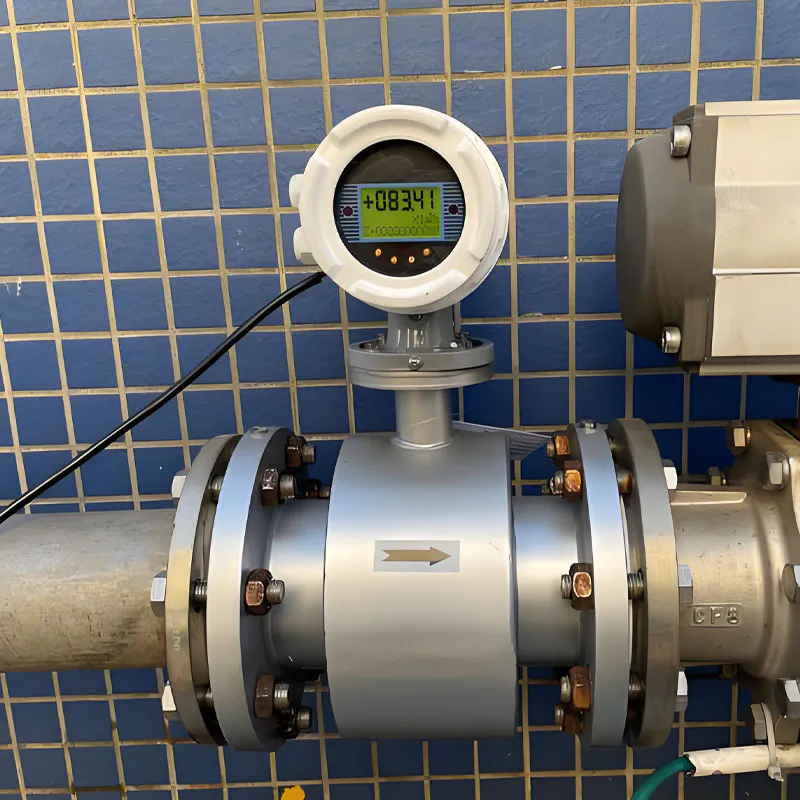

Flow Meter Description

Electromagnetic Flowmeter-Features

The electromagnetic flowmeter delivers stable electromagnetic flow measurement that is independent of fluid density, viscosity, temperature, pressure, and conductivity, reducing recalibration frequency and long-term operating costs.

With a full-bore design and no moving parts, the electromagnetic flow meter eliminates pressure loss and minimizes maintenance, making it ideal for continuous operation in slurry, wastewater, and corrosive liquid applications.

A wide DN6–DN3000 size range, combined with multiple lining and electrode material options, allows one electromagnetic flowmeter platform to cover diverse processes, reducing spare parts inventory and total cost of ownership.

Advanced low-frequency rectangular wave excitation and full digital signal processing ensure high measurement stability and strong anti-interference performance, even in electrically noisy industrial environments.

The 32-bit embedded processor enables fast signal calculation and a wide measurement range of up to 1500:1, allowing accurate flow monitoring under both low-flow and peak-load conditions without changing instruments.

Integrated diagnostics, empty pipe detection, and conductivity monitoring improve operational safety and reduce unexpected downtime, supporting predictive maintenance strategies.

Multiple industrial communication protocols, including RS485, HART, and optional Profibus, ensure seamless system integration and protect automation investments over the long term.

Explosion-proof options and robust SMT-based electronics provide reliable performance in hazardous and harsh environments, extending service life and maximizing return on investment.

Electromagnetic Flow Meter-Applications

Water & Wastewater

Electromagnetic flowmeters are used for raw water intake, distribution pipelines, effluent discharge, and sludge measurement, providing stable electromagnetic flow measurement for municipal and industrial water systems.

Chemical & Pharmaceutical

Electromagnetic flowmeters measure corrosive chemicals, acids, alkalis, and process liquids with high accuracy, supported by multiple lining and electrode options for chemical compatibility.

Food & Beverage

Sanitary electromagnetic flow meters are applied to beverages, dairy products, syrups, and process water, supporting hygienic electromagnetic flow measurement and batch consistency.

Pulp & Paper

Electromagnetic flowmeters are suitable for stock preparation, white water circulation, chemical dosing, and wastewater monitoring in fiber-rich process environments.

Power & Cooling Water

Electromagnetic flowmeters monitor cooling water circulation and auxiliary water systems, helping improve system efficiency and operational reliability.

Mining & Slurry

Electromagnetic flowmeters are ideal for abrasive slurry, tailings, and mineral processing fluids, delivering reliable electromagnetic flow measurement in harsh industrial conditions.

Electromagnetic Flowmeters-Measuring Principle

The measuring principle of an electromagnetic flowmeter is based on Faraday’s law of electromagnetic induction. The measuring tube is a non-magnetic alloy spool lined with an insulating material to ensure stable electromagnetic flow measurement and eliminate signal interference.

Two electrodes are mounted diametrically through the pipe wall and fixed on the measuring tube, with the electrode surfaces flush with the inner lining. When the excitation coils are driven by a bidirectional pulsed current, a working magnetic field with a magnetic flux density B is generated in a direction perpendicular to the pipe axis.

As a conductive fluid flows through the measuring tube of the electromagnetic flow meter, it cuts the magnetic field lines and an induced electromotive force E is generated. The induced voltage is directly proportional to the magnetic flux density B, the inner diameter of the measuring tube d, and the average flow velocity v of the fluid.

The electromotive force E, which represents the electromagnetic flow measurement signal, is detected by the electrodes and transmitted to the converter via shielded cables. The converter amplifies and processes the signal, calculates the flow rate, and displays the measurement result. Standard output signals such as pulse output and analog current (4–20 mA) are provided for flow monitoring, control, and process regulation in industrial automation systems.

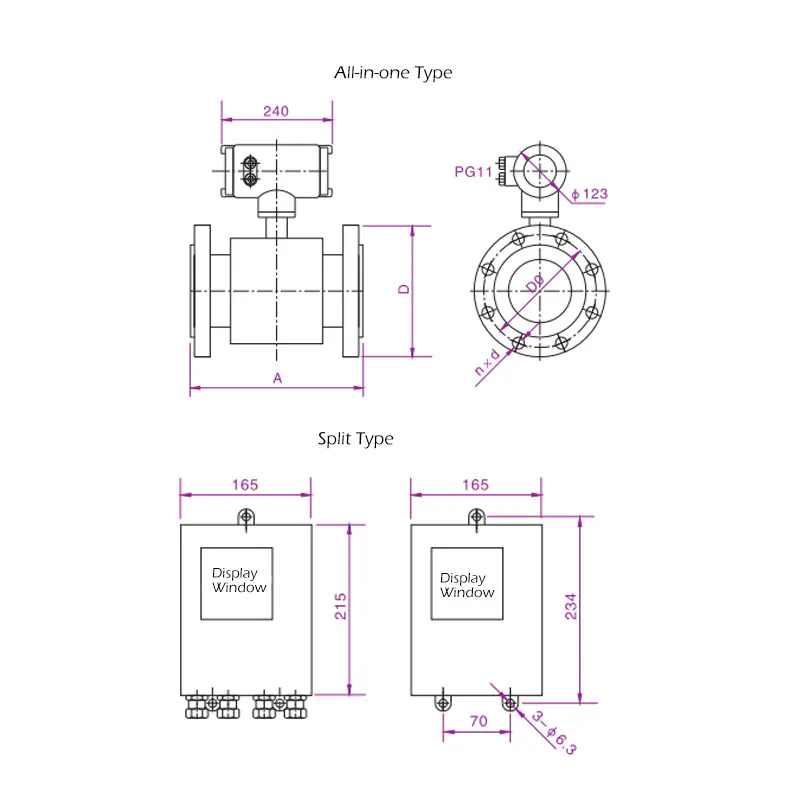

Flowmeter Electromagnetic-Structure

| Selection Item | Integral Electromagnetic Flowmeter | Remote Electromagnetic Flowmeter |

|---|---|---|

| Structure | Sensor and converter integrated into one unit | Sensor and converter installed separately |

| Typical Application | Standard industrial environments | Harsh or complex installation environments |

| Ambient Temperature | Suitable for moderate temperatures | Recommended when ambient or radiant temperature exceeds 60°C |

| Pipeline Vibration | Suitable for low-vibration pipelines | Better for strong or continuous vibration conditions |

| Corrosive Environment | Limited resistance if exposed to corrosive gases | Converter can be installed in a safe, non-corrosive area |

| Installation Accessibility | Easy local operation and commissioning | Ideal for high or hard-to-access installation points |

| Maintenance & Operation | Simple wiring, quick installation | Easier maintenance with remote access to the converter |

| Installation Flexibility | Compact, space-saving design | High flexibility for sensor and converter placement |

| Cable Length Requirement | No separation cable required | Sensor–converter distance up to 100 m (to be specified when ordering) |

| Converter Mounting | Integrated on the sensor | Wall-mounted converter as standard |

| Recommended Users | Cost-sensitive projects with standard conditions | Projects prioritizing reliability, safety, and long-term stability |

Flow Meter Parameter

| PTFE Lined Pipe(Dn) | 10, 15, 20, 25, 32, 40, 50, 65, 80, 100, 125, 150, 200, 250, 300, 350, 400, 450, 500, 600 |

| Rubber Lined Pipe(Dn) | 40, 50, 65, 80, 100, 125, 150, 200, 300, 350, 400, 500, 600, 800, 1000, 1200, note: special specifications can be customized |

| Measuring Range Ratio | 150:01:00 |

| Repeatability Error | +/-0.1% |

| Accuracy | Piped: 0.5 class, 1.0 class |

| Measured Medium Temperature | Common rubber lining: -20~+60 ° c |

| High temperature rubber lining: -20~+90 ° c | |

| PTFE lining: -30~+100 ° c | |

| High temperature vinyl lining: -30~+180 ° c | |

| Rated working pressure | Pipeline: DN10~DN65: ≤ 2.5MPa;DN80~DN150: ≤ 1.6MPa; |

| DN200~DN1200: ≤ 1.0MPa | |

| Flow Measuring Range | Flow measuring range corresponding to flow rate range is 0.3~15m/s |

| Measured Fluid Conductivity | 5μs/cm (Most with water as the composition of the medium, its conductivity in the range 200~800 Mu s/cm, optional solenoid flow) |

| Output | Current:4~20mADC (isolation), pulse frequency 0~1kHz, OCT photoelectric isolation, external power ≤ 35VDC, breakover, collector Max 25mA |

| Electrode Material | 316L, titanium (Ti), tantalum (Ta), Hastelloy, (h), Platinum (Pt) or other special electrode materials |

Flow Meter OEM/ODM

Electromagnetic Flowmeter – OEM / ODM

As a professional electromagnetic flowmeter manufacturer, we provide comprehensive OEM and ODM services to support customized electromagnetic flow measurement solutions for global industrial applications.

Our OEM electromagnetic flowmeter service allows customers to apply their own brand identity, including logo, nameplate, housing color, and packaging, while maintaining stable performance and consistent quality standards. This is ideal for distributors, system integrators, and automation solution providers.

Through ODM customization, we support full product development based on specific application requirements. Customization options include nominal diameter, flow range, lining materials, electrode materials, pressure rating, power supply, and communication protocols such as 4–20 mA, HART, Modbus, and Profibus. Explosion-proof and high-protection designs are also available for demanding environments.

Each customized electromagnetic flow meter is engineered, assembled, and tested in-house to ensure measurement accuracy, long-term stability, and compatibility with the target process conditions. This OEM / ODM capability enables customers to reduce development time, control total cost of ownership, and accelerate market entry.

Related Product Recommendations

An electromagnetic flowmeter is designed for electromagnetic flow measurement of conductive liquids only. Typical measurable media include water, wastewater, acids, alkalis, slurry, pulp, chemicals, and process liquids.

The minimum conductivity requirement is usually ≥5 μS/cm (some models ≥1 μS/cm with special excitation).

| Liquid Type | Suitability | Notes |

|---|---|---|

| Clean water | Excellent | Most common application |

| Wastewater | Excellent | Not affected by impurities |

| Slurry | Excellent | No moving parts, no blockage |

| Oil / Gas | Not suitable | Non-conductive |

| Deionized water | Limited | Conductivity must be verified |

This makes the electromagnetic flow meter especially suitable for water treatment, chemical processing, and slurry transport.

standard industrial electromagnetic flowmeter typically offers an accuracy of ±0.5% of reading, with high-end models reaching ±0.3%. Accuracy remains stable because electromagnetic flow measurement is independent of fluid density, viscosity, pressure, and temperature.

| Flowmeter Type | Typical Accuracy | Moving Parts |

|---|---|---|

| Electromagnetic flowmeter | ±0.3% – ±0.5% | No |

| Turbine flowmeter | ±0.5% – ±1.0% | Yes |

| Ultrasonic flowmeter | ±0.5% – ±1.0% | No |

| Orifice plate | ±1.0% – ±2.0% | No |

For long-term ROI and low maintenance, electromagnetic flow meters are often preferred in continuous industrial processes.

Electromagnetic flowmeters support a very wide nominal diameter range, typically from DN6 to DN3000, making them suitable for both small dosing lines and large pipelines.

| Parameter | Range |

|---|---|

| Nominal diameter | DN6 – DN3000 |

| Flow velocity | 0.1 – 10 m/s |

| Measurement range ratio | Up to 1500:1 |

This wide range allows one electromagnetic flowmeter platform to cover multiple applications, reducing spare parts inventory and system complexity.

The performance and service life of an electromagnetic flowmeter depend heavily on correct material selection. Different media require different lining and electrode combinations to ensure corrosion resistance and signal stability.

| Medium | Lining Material | Electrode Material |

|---|---|---|

| Water / wastewater | Rubber / PTFE | SS316L |

| Acid / alkali | PTFE / PFA | Hastelloy |

| Slurry | Rubber / Ceramic | SS316L / Hastelloy |

| High corrosion | PTFE | Tantalum |

Proper material selection improves measurement reliability and significantly reduces total cost of ownership.

Modern electromagnetic flowmeters support multiple analog and digital outputs for seamless integration into automation systems.

| Output Type | Purpose |

|---|---|

| 4–20 mA | Process control |

| Pulse | Flow totalization |

| RS485 / Modbus | PLC and SCADA |

| HART | Configuration and diagnostics |

| Profibus | Industrial networks (optional) |

These communication options ensure the electromagnetic flow meter remains compatible with current and future control systems.

As an OEM / ODM manufacturer, we provide deep customization for electromagnetic flowmeters to match specific project requirements and branding needs.

| Customization Item | OEM | ODM |

|---|---|---|

| Logo & nameplate | Yes | Yes |

| Housing color | Yes | Yes |

| Diameter & pressure | Limited | Fully customizable |

| Lining & electrode | Standard options | Application-specific |

| Communication protocol | Optional | Fully selectable |

| Explosion-proof design | Optional | Custom certified |

OEM electromagnetic flowmeter solutions help customers shorten delivery time, while ODM solutions support differentiated products and faster market entry.

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.