Transmitter

Home » Products » Transmitters » Guided Wave Radar Level Transmitter

Guided Wave Radar Level Transmitter

Reliable Contact Level Measurement for Complex Process Conditions

The guided wave radar level transmitter is a contact-type level measurement instrument based on time-domain reflectometry (TDR) technology. It transmits low-energy microwave pulses along a probe (rod or cable). When the signal encounters a change in dielectric constant at the material surface, part of the signal is reflected back to the transmitter and analyzed to determine the level.

Compared with non-contact radar, guided wave radar provides stronger signal coupling, making it especially suitable for applications involving narrow vessels, internal structures, turbulence, foam, or low dielectric media.

Instrava’s guided wave radar solutions are designed for stable, repeatable, and maintenance-friendly level measurement in demanding industrial process environments.

Transmitter Description

Guided Wave Radar Level Transmitter Features

Thanks to an advanced microprocessor and proprietary echo processing technology, the guided wave radar level transmitter delivers stable and reliable measurement under a wide range of complex process conditions.

The flexible selection of process connections and probe designs enables the instrument to operate effectively in applications involving high temperature, high pressure, and low dielectric constant media.

Operating in pulsed mode with extremely low transmission power, the guided wave radar level transmitter can be safely installed in metal and non-metal vessels. The measurement process is harmless to personnel and the environment, making it suitable for safety-critical industrial applications.

Guided Wave Radar Level Transmitters Typical Applications

Storage tanks and process vessels

Chemical and petrochemical industries

Power generation and boiler auxiliary systems

Oil, fuel, and condensate level measurement

Applications with foam, agitation, or internal obstructions

Situations where ultrasonic or non-contact radar is unstable

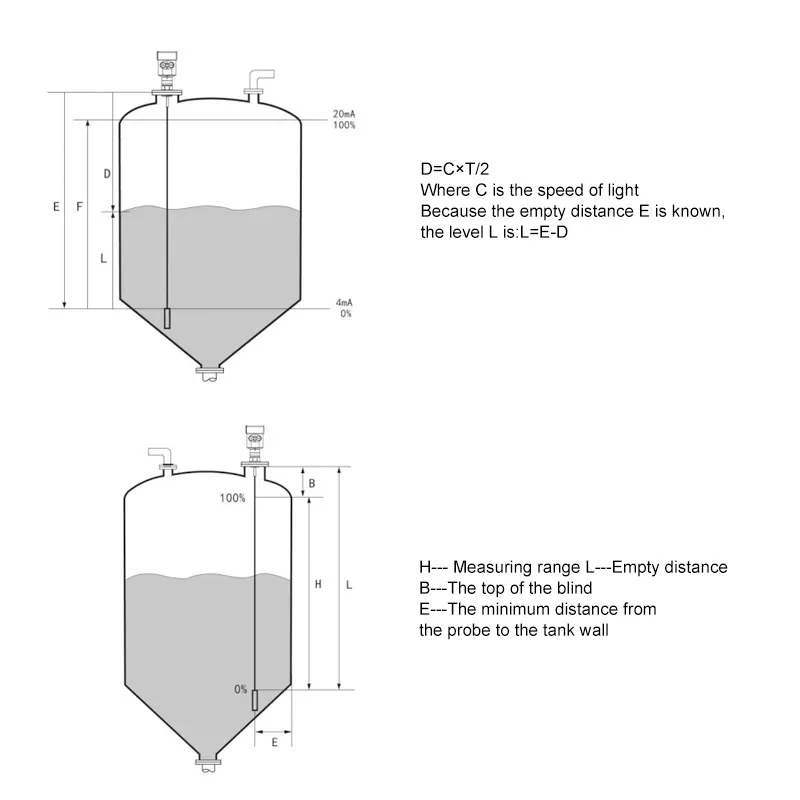

Guided Wave Level Transmitter Working Principle

The guided wave radar level transmitter operates by emitting high-frequency microwave pulses that propagate along a detection probe, such as a steel rod or steel cable.

When the microwave pulse reaches the surface of the measured medium, a sudden change in dielectric constant occurs. This discontinuity causes part of the pulse energy to be reflected back toward the transmitter.

The instrument measures the time interval between the transmitted pulse and the received echo. This time difference is directly proportional to the distance between the probe reference point and the material surface. Based on this relationship, the transmitter accurately calculates the level of the medium inside the vessel.Guided Wave Level Transmitter

Guided Wave Radar Type Level Transmitter Structure and Reliability Design

The transmitter consists of a robust electronic head and a mechanically stable probe structure. The probe guides the radar signal directly to the measurement point, minimizing interference from tank walls, nozzles, or internal components.

With no moving parts and a sealed industrial enclosure, the guided wave radar level transmitter offers long service life, low maintenance requirements, and high operational reliability in harsh environments.

Transmitter Parameter

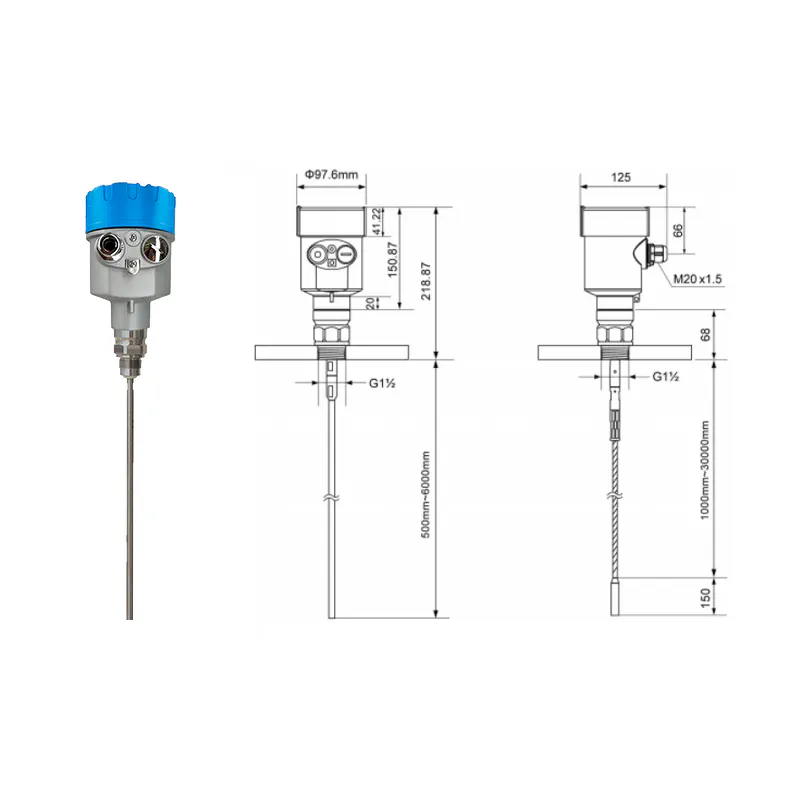

Model: INGWRLT115

| Item | Specification |

|---|---|

| Suitable Measuring Medium | Liquid, solid powder |

| Typical Application | Liquid and solid level measurement under complex process conditions |

| Measuring Range | Up to 30 m |

| Measuring Principle | Guided Wave Radar (TDR) |

| Probe Type | Single cable probe / Single rod probe |

| Operating Frequency | 500 MHz – 1.8 GHz |

| Measurement Accuracy | ±10 mm |

| Process Temperature | -40 ~ 250 °C |

| Process Pressure | -0.1 ~ 4.0 MPa |

| Signal Output | 4–20 mA + HART |

| Power Supply | Two-wire: DC 24 V Four-wire: DC 24 V / AC 220 V |

| Local Display | 4-line LCD, programmable |

| Explosion Protection | Ex ia IIC T6 Ga Ex d IIC T6 Gb |

| Process Connection | Flange (optional) / Thread |

| Housing Material | Aluminum / Plastic |

Transmitter OEM/ODM

Customization & Instrava Support

Instrava provides customized guided wave radar level transmitter solutions to meet specific process requirements. Probe type (rod or cable), probe length, process connection, material compatibility, and output configuration can be tailored to your application.

As a partner focused on industrial measurement and control instruments for safety-critical and process control applications, Instrava works closely with customers and OEM partners to deliver reliable, long-lasting solutions. Through trust, communication, and collaboration, we help customers optimize processes and improve operational efficiency.

Yes. The guided wave radar level transmitter uses a probe-guided microwave signal that travels directly along the rod or cable. Unlike non-contact technologies, foam has limited influence on signal propagation, allowing the instrument to detect the true material surface beneath the foam layer.

Guided wave radar provides stronger signal coupling compared to non-contact radar. By guiding the microwave energy along the probe, INGWRLT115 ensures reliable signal reflection even in media with low dielectric constants, where ultrasonic or non-contact radar may become unstable.

Yes. INGWRLT115 is designed for process temperatures up to 250 °C. The probe-based measurement principle ensures stable signal transmission under elevated temperatures, making it suitable for demanding thermal process environments.

INGWRLT115 supports process pressures up to 4.0 MPa. Its robust probe structure and sealed process connection maintain measurement stability under pressure fluctuations commonly found in chemical and industrial process vessels.

Since the radar signal is guided along the probe, turbulence and surface agitation have minimal impact on measurement accuracy. INGWRLT115 maintains a stable echo reference even in vessels with strong mixing or flow disturbance.

Guided wave radar measurement is largely immune to vapor and condensation. The microwave signal is transmitted along the probe rather than through free space, reducing interference from vapor clouds or condensate buildup inside the vessel.

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.