Confined Space Gas Detection Safety | Portable Detectors and Oxygen Monitoring

Confined spaces are among the most hazardous work environments in industrial facilities. Limited ventilation, restricted access, and the potential accumulation of toxic or oxygen-displacing gases make confined space gas detection a critical component of industrial safety programs. Across oil & gas facilities, LNG/LPG storage terminals, chemical plants, and wastewater treatment operations, effective gas detection is often the deciding factor between safe entry and serious incidents.This article explains confined space

gas detection safety from an engineering and operational perspective, focusing on hazard identification, portable gas detector use, oxygen monitoring, and correct response procedures.

What Is a Confined Space?

A confined space is typically defined as an area that:

- Is large enough for a worker to enter

- Has limited or restricted means of entry or exit

- Is not designed for continuous occupancy

Common industrial examples include tanks, vessels, silos, pits, manholes, pipelines, and underground chambers.

Why Gas Detection Is Critical in Confined Spaces

Gas hazards in confined spaces can develop rapidly and without warning. The most common risks include:

- Oxygen deficiency caused by nitrogen, argon, or carbon dioxide displacement

- Toxic gas accumulation such as hydrogen sulfide (H₂S) or carbon monoxide (CO)

- Flammable atmospheres created by methane, propane, or solvent vapors

Because these hazards are often invisible and odorless, gas detection provides the only reliable means of protection.

Primary Gases Monitored in Confined Space Safety

| Gas Type | Examples | Typical Risk | Detection Objective |

|---|

| Oxygen | O₂ deficiency or enrichment | Asphyxiation, fire risk | Maintain safe breathing atmosphere |

| Toxic gases | H₂S, CO, NH₃ | Acute health effects | Exposure prevention |

| Flammable gases | Methane, propane | Fire and explosion | LEL monitoring |

Understanding which gases may be present is the foundation of effective confined space gas detection.

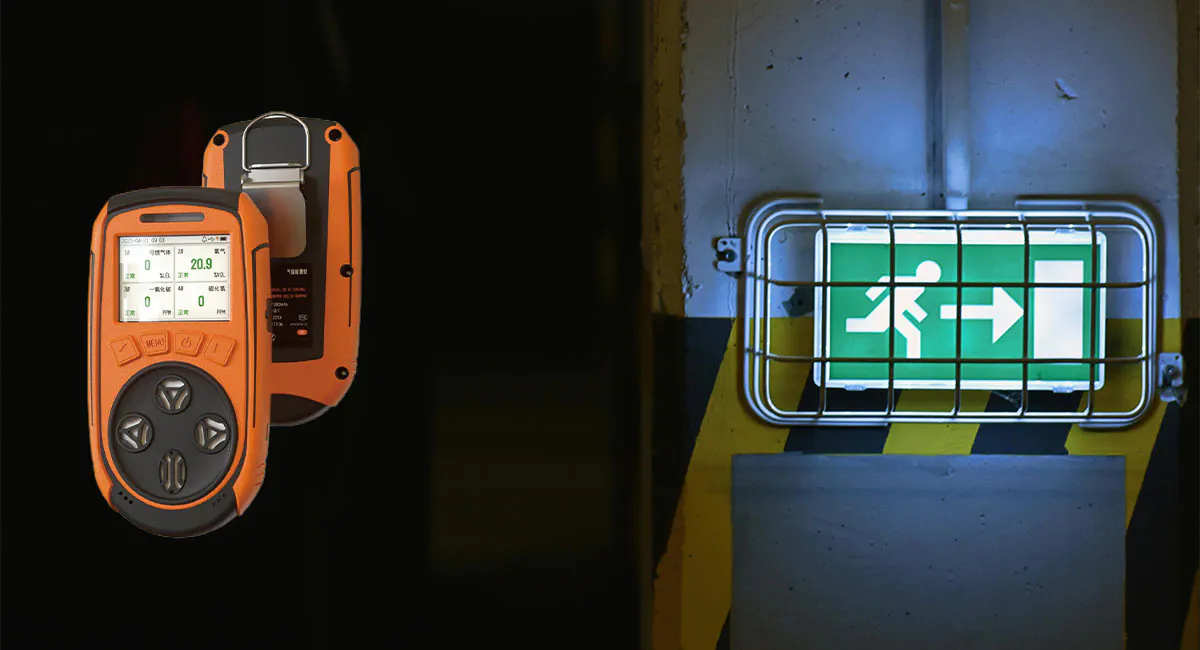

Role of Portable Gas Detectors in Confined Spaces

Portable gas detectors are the primary tools used for confined space entry and work activities.

Key Functions

- Pre-entry atmospheric testing

- Continuous monitoring during occupancy

- Audible, visual, and vibration alarms

- Personal protection within the breathing zone

Portable detectors are typically worn on the chest or collar to ensure accurate exposure monitoring.

Oxygen Monitoring: The First Priority

Oxygen levels in confined spaces can change quickly due to chemical reactions, purging operations, or leaks of inert gases.

- Oxygen deficiency (<19.5%) can cause dizziness, loss of consciousness, or death

- Oxygen enrichment (>23.5%) increases fire and explosion risk

Continuous oxygen monitoring is therefore a mandatory element of confined space gas detection safety.

Single Gas vs Multi-Gas Detection in Confined Spaces

Both

single gas and multi-gas detection play important roles in confined space safety.

| Detection Type | Typical Use |

|---|

| Single gas detection | Continuous oxygen or H₂S monitoring during work |

| Multi-gas detection | Pre-entry testing and unknown atmosphere assessment |

Many safety programs combine both approaches to ensure layered protection.

Pre-Entry Gas Testing Procedures

Before entering a confined space, atmospheric testing should confirm:

- Safe oxygen concentration

- Absence of toxic gases above exposure limits

- Flammable gas levels below LEL thresholds

Testing should be performed from outside the space whenever possible and at multiple levels if stratification is possible.

Continuous Monitoring During Confined Space Work

Gas conditions can change during work due to:

- Hot work

- Chemical reactions

- Process residue release

- Ventilation failure

Continuous portable gas detection ensures immediate warning if conditions become unsafe.

Alarm Response and Emergency Actions

When a gas detector alarm activates in a confined space:

- Stop work immediately

- Evacuate the space without delay

- Do not attempt rescue without proper equipment

- Ventilate and re-test before re-entry

Prompt response is essential to prevent secondary incidents.

Ventilation and Gas Control Measures

Gas detection works best when combined with effective ventilation strategies:

- Forced air ventilation before and during entry

- Continuous exhaust in high-risk spaces

- Verification of ventilation effectiveness using gas detectors

Detection confirms whether ventilation is achieving safe conditions.

Maintenance and Reliability of Gas Detection Equipment

Confined space gas detectors must be reliable at all times.Recommended practices include:

- Bump testing before each use

- Regular calibration according to safety procedures

- Sensor inspection and replacement as required

Equipment reliability directly impacts worker safety.

Alignment with Confined Space Safety Programs

Gas detection is one element of a broader confined space safety framework, which typically includes:

- Permit systems

- Trained attendants and supervisors

- Rescue planning

- Lockout and isolation procedures

Gas detection data supports informed decision-making throughout the entry process.

Conclusion

Confined space gas detection safety is essential for preventing injuries and fatalities in industrial environments. By combining thorough hazard assessment, effective portable gas detection, continuous oxygen monitoring, and disciplined response procedures, facilities can significantly reduce confined space risks.When gas detection is integrated into a structured confined space program, it becomes a proactive safety tool—protecting workers before conditions escalate into emergencies.