- By Instrava

- 01/10/2026

- 0 Comment

Gas Detector Controller vs PLC/DCS: How to Design a Reliable Industrial Gas Safety System

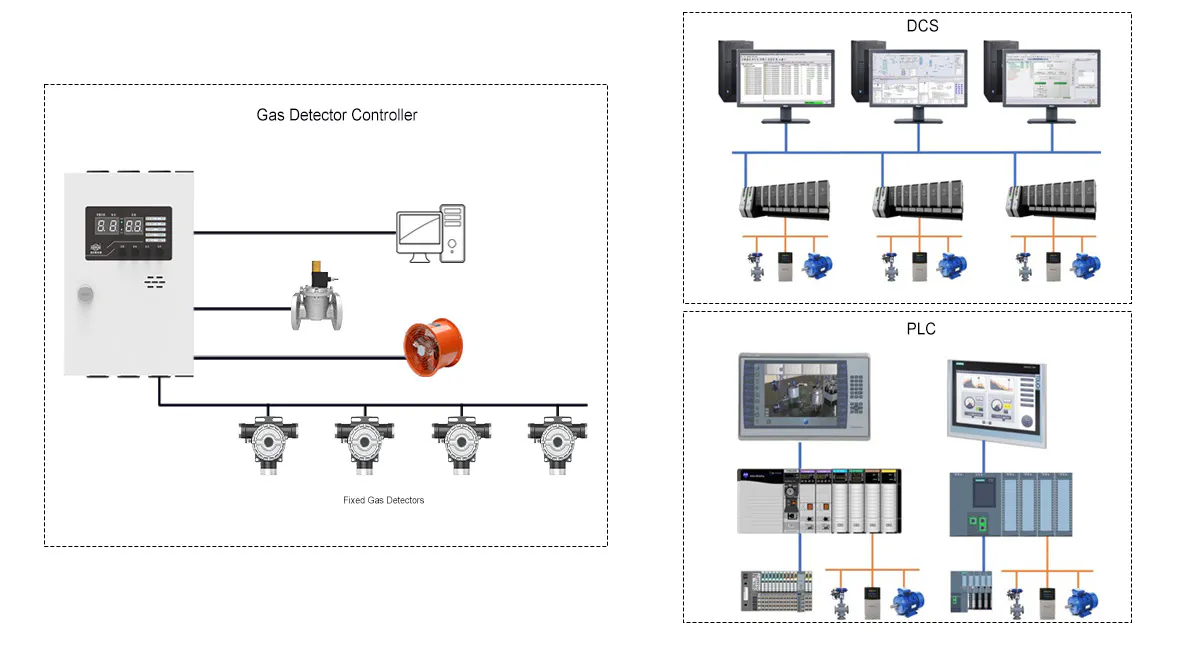

In industrial environments where flammable or toxic gases are present, gas detection systems are often integrated into broader automation architectures. A common engineering question during project design is whether gas detection should rely on a dedicated gas detector controller or be fully integrated into an existing PLC or DCS system.

Understanding the functional differences between these approaches is critical for ensuring safety, reliability, and regulatory compliance.

1. System Design Philosophy: Safety System vs Process Control

The fundamental distinction lies in system intent.

Gas detector controllers are designed as safety-focused systems

PLC/DCS platforms are designed primarily for process control and optimization

Gas detection is a safety-critical function, requiring deterministic behavior, fail-safe logic, and continuous availability—even during process downtime or maintenance.

2. What a Gas Detector Controller Is Designed to Do

A gas detector controller acts as a centralized safety hub, collecting signals from multiple gas detectors and executing predefined safety responses.

Core Functions:

Continuous monitoring of flammable and toxic gases

Independent alarm processing

Redundant power and fault monitoring

Dedicated audible and visual alarm outputs

Event logging for safety audits

Instrava supports industrial gas detection architectures where dedicated controllers ensure safety functions remain independent from process control layers.

3. PLC / DCS-Based Gas Detection: Strengths and Limitations

PLCs and DCS platforms are powerful automation tools, but when used for gas detection, they introduce important considerations.

Advantages

Easy integration with existing automation infrastructure

Unified operator interface

Flexible logic programming

Suitable for low-risk or non-critical environments

Limitations

Gas detection logic depends on PLC runtime and scan cycles

Maintenance or software updates may temporarily disable gas monitoring

Alarm prioritization may compete with process alarms

Functional safety certification may be required but not always implemented

4. Functional Comparison Table

| Aspect | Gas Detector Controller | PLC / DCS Integration |

|---|---|---|

| Primary Purpose | Safety monitoring | Process control |

| Independence | Fully independent | Dependent on automation system |

| Response Time | Deterministic, fixed | Variable (scan cycle dependent) |

| Fail-Safe Design | Native | Requires custom programming |

| Maintenance Impact | Minimal | May interrupt gas monitoring |

| Regulatory Acceptance | High | Conditional |

| Alarm Reliability | Dedicated | Shared with process alarms |

5. Alarm Management and Response Reliability

Gas detector controllers are engineered to prioritize safety alarms above all other signals.

Typical safety actions include:

Immediate audible and visual alarms

Activation of ventilation systems

Interlocks for emergency shutdown

Relay outputs independent of software logic

When gas detection relies solely on PLC or DCS logic, alarm execution may be delayed or suppressed due to:

CPU overload

Maintenance modes

Operator configuration changes

This difference becomes critical in explosive or toxic environments.

6. Redundancy and Fail-Safe Behavior

Safety standards emphasize that gas detection systems must continue functioning during abnormal conditions.

Controller-Based Systems

Independent power supply

Communication loss detection

Watchdog and self-diagnostics

Alarm on system fault

PLC/DCS-Based Systems

Redundancy depends on system architecture

Often requires additional safety PLCs

Higher engineering complexity

Instrava solutions are typically deployed where independent safety layers are required to reduce single-point failures.

7. Regulatory and Compliance Considerations

Many international safety guidelines implicitly or explicitly favor dedicated safety systems for gas detection:

IEC 61508 / IEC 61511 – Functional safety separation

NFPA / EN standards – Independent gas alarm systems

OSHA guidance – Reliable and continuous hazard monitoring

While PLC/DCS integration is permitted, it often requires:

Safety-rated PLCs

Formal SIL analysis

Additional documentation and validation

8. Hybrid Architecture: The Best of Both Worlds

In modern industrial facilities, the most effective approach is often a hybrid system:

Gas detector controller

→ Handles real-time safety monitoring and alarmsPLC / DCS

→ Receives status signals, alarms, and trends for visualization and reporting

This architecture ensures:

Safety independence

Operator visibility

Reduced engineering risk

Easier compliance

Instrava supports this hybrid approach by enabling safe, structured integration between gas detection controllers and automation systems.

9. Common Engineering Decision Guide

| Facility Type | Recommended Architecture |

|---|---|

| Oil & Gas Processing | Dedicated controller + DCS interface |

| LNG / LPG Storage | Dedicated controller (mandatory) |

| Chemical Manufacturing | Hybrid controller + PLC |

| Utility Plants | Controller-based or hybrid |

| Low-Risk Industrial Areas | PLC integration (case-dependent) |

10. Conclusion

Choosing between a gas detector controller and PLC/DCS integration is not a question of capability, but of risk management and safety philosophy.

For safety-critical environments, dedicated gas detector controllers provide:

Deterministic response

Fail-safe operation

Regulatory confidence

Long-term reliability

By combining controllers with PLC or DCS systems in a structured way, industrial facilities can achieve both safety assurance and operational efficiency.

Instrava works with industrial users and system integrators to design gas detection architectures that balance safety integrity, system reliability, and practical operation.