Level Measuring Instruments

Home » Products » Level Measuring Instruments » Glass Level Gauge » Glass Tube Level Gauge for Accurate Visual Level Measurement

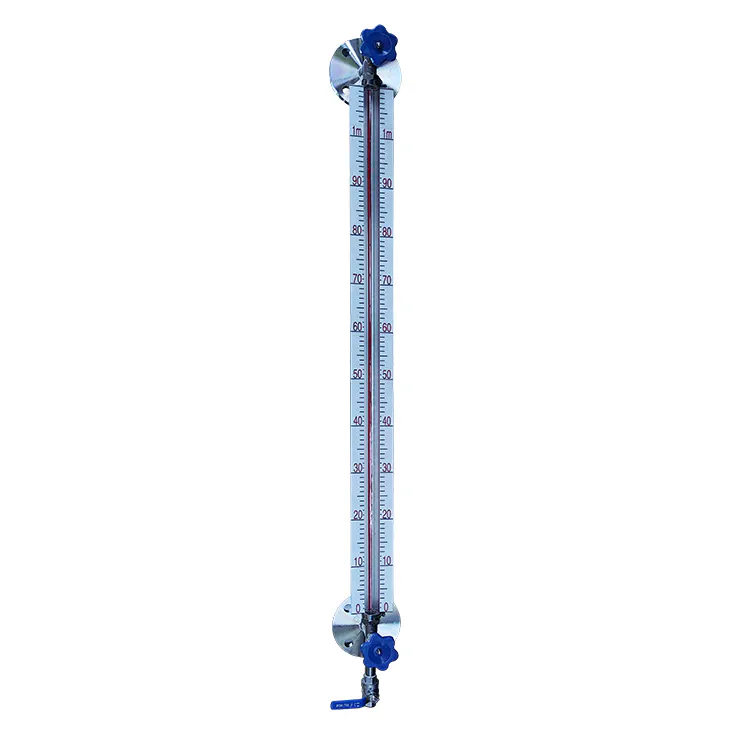

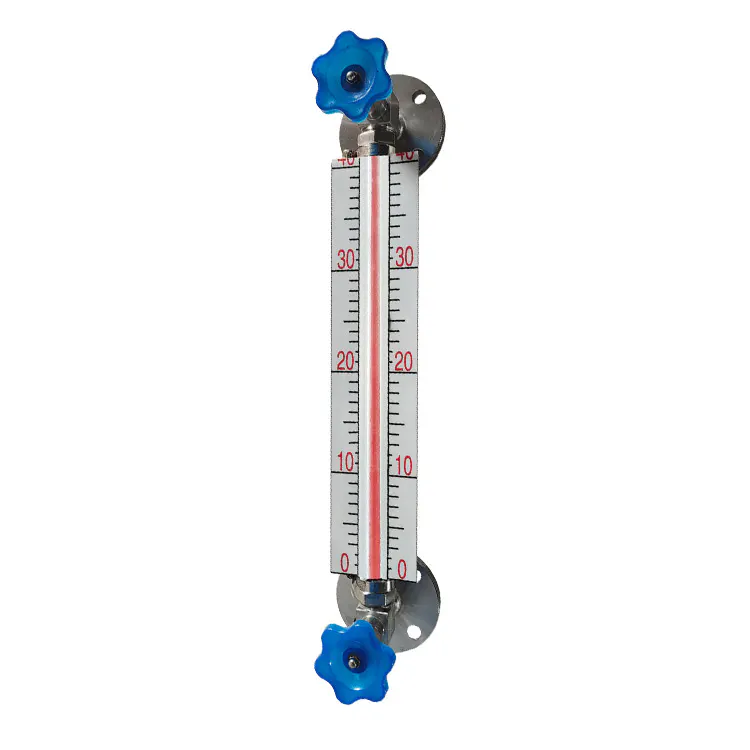

Glass Tube Level Gauge for Accurate Visual Level Measurement

A glass tube level gauge is a simple and reliable visual level indication device used to directly observe liquid levels in tanks, vessels, and industrial systems. By using a transparent glass tube connected to the process vessel, operators can clearly monitor real-time liquid levels without complex instrumentation.

We provide glass tube level gauges designed for stable performance, easy installation, and clear visibility in a wide range of industrial applications.

Level Measuring Instruments Description

Key Features of Glass Tube Level Gauge

Direct visual indication of liquid level

Simple structure with reliable performance

Transparent glass tube for clear observation

Easy installation and maintenance

Suitable for low to medium pressure applications

Cost-effective solution for level monitoring

Typical Applications of Glass Tube Level Gauges

Glass tube level gauges are commonly used in:

Water tanks and storage vessels

Low-pressure industrial tanks

Chemical processing equipment

Utility and auxiliary systems

Non-critical level monitoring applications

How a Glass Tube Level Gauge Works

Direct visual indication of liquid level

Simple structure with reliable performance

Transparent glass tube for clear observation

Easy installation and maintenance

Suitable for low to medium pressure applications

Cost-effective solution for level monitoring

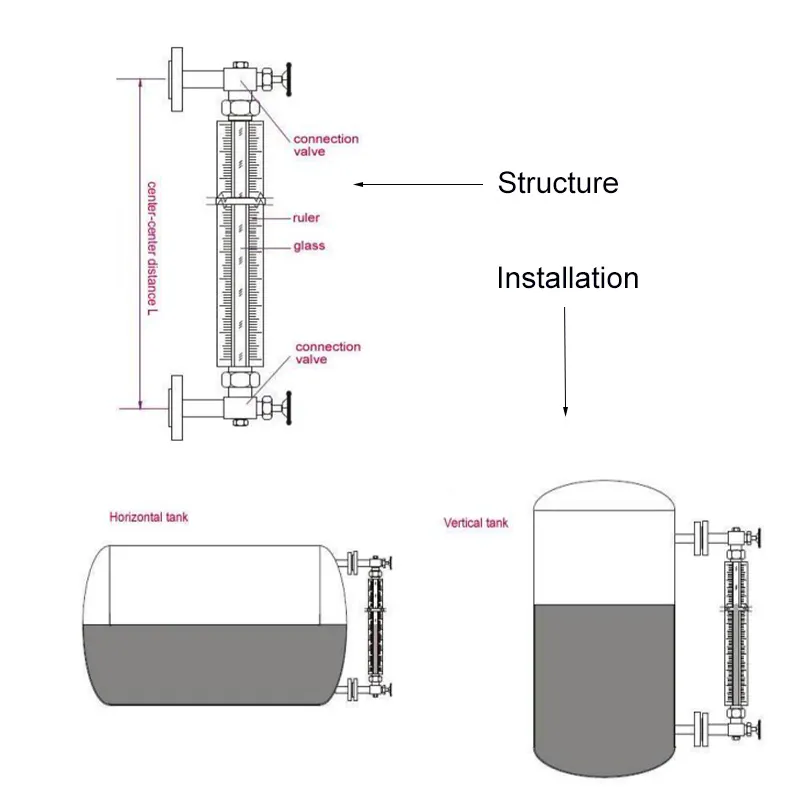

Glass Tube Level Gauge Structural Design

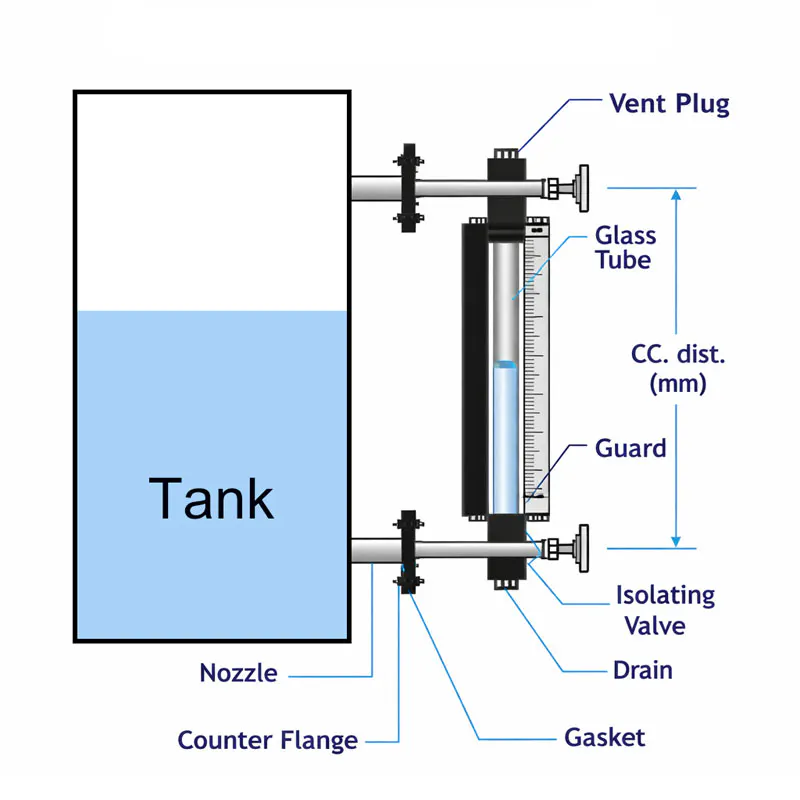

A glass tube level gauge features a simple and robust structure designed for direct visual level indication. The main components typically include:

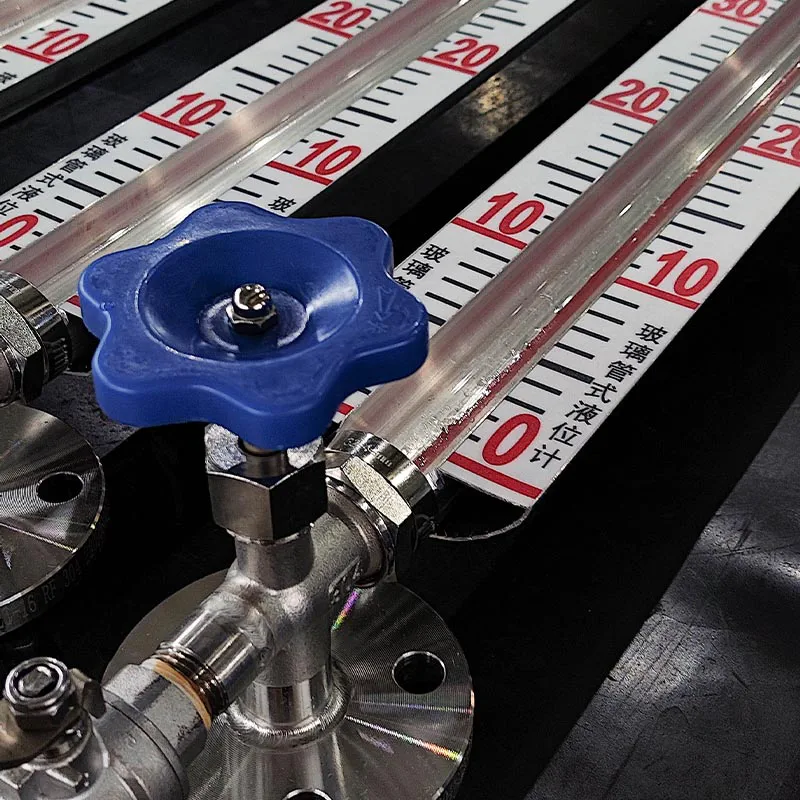

Transparent glass tube

The glass tube is the core component, allowing operators to visually observe the liquid level. Borosilicate glass is commonly used for its good transparency, temperature resistance, and chemical stability.Upper and lower process connections

These connections link the glass tube to the tank or vessel, ensuring the liquid level inside the tube matches the actual process level based on the communicating vessel principle.Metal body and fittings

The body and fittings are usually made of carbon steel or stainless steel to provide mechanical support and corrosion resistance.Sealing components

Gaskets and seals ensure leak-tight performance during operation.

This straightforward structure allows the glass tube level gauge to operate reliably with minimal maintenance requirements.

Level Measuring Instruments Parameter

| Item | Specification |

|---|---|

| Model | INGT114 |

| Recommended Center-to-Center Distance | 300 mm, 500 mm, 800 mm, 1100 mm, 1400 mm, 1700 mm, 2000 mm (custom made available) |

| Indication Mode | Single color; Bi-color (red for vapor phase, green for liquid phase) |

| Material | Carbon steel; Stainless steel 304 / 316L; 1Cr18Ni9Ti; 0Cr18Ni9; 304 with PTFE lining |

| Nominal Pressure | PN6 – PN100 (×0.1 MPa) 304 + PTFE ≤ PN40 |

| Working Temperature | Carbon steel ≤ 350 °C Stainless steel ≤ 450 °C 304 + PTFE ≤ 200 °C PP ≤ 100 °C |

| Drain Valve | Drain needle valve (customizable) |

| Vent Valve | Vent needle valve (customizable) |

| Process Connection (Flange) | DN20 / RF, HG/T 20592-09 |

| Heating Steam Interface | ZG 1/2″ male screw thread |

| Heating Steam Pressure | ≤ 1.0 MPa |

| Electric Heating | Self-limiting temperature heating (not required for anticorrosive type) |

| Steel Ball Self-Closing Pressure | ≥ 0.3 MPa |

| Power Supply | 24 V DC, 36 V AC |

| Ambient Temperature | –50 °C to +80 °C |

Level Measuring Instruments OEM/ODM

Customization & OEM Service

Glass tube level gauges can be customized according to specific operating conditions, including:

Center-to-center distance

Material selection

Pressure rating

Connection standards

Valve configuration

Protective covers or shields

Instrava is a partner focused on providing equipment, solutions, and services for industrial measurement and control instruments used in safety-critical and process control applications. We are committed to delivering reliable and long-lasting solutions based on trust, communication, and collaboration, helping customers improve processes and operational efficiency.

As a trusted long-term partner for customers and OEM partners in China, Instrava provides professional OEM and customization services for glass tube level gauges and other industrial level measurement instruments.

Related Product Recommendations

The INGT114 glass tube level gauge supports nominal pressures from PN6 to PN100. For configurations with 304 stainless steel and PTFE lining, the maximum nominal pressure is PN40.

Yes. The INGT114 glass tube level gauge is available with standard center-to-center distances ranging from 300 mm to 2000 mm, and custom lengths can be manufactured based on installation requirements.

The bi-color indication of the INGT114 glass tube level gauge is suitable for applications where clear phase differentiation is required. Red indicates the vapor phase, while green indicates the liquid phase, improving visibility during operation.

For corrosive process media, the INGT114 glass tube level gauge can be supplied with stainless steel materials such as 316L or with a 304 stainless steel body featuring a PTFE lining to improve corrosion resistance.

Electric heating is optional. The INGT114 can be equipped with self-limiting temperature electric heating when required, while anticorrosive configurations generally do not require additional heating.

The INGT114 glass tube level gauge includes a steel ball self-closing mechanism that activates at pressures ≥ 0.3 MPa, helping to reduce liquid leakage in the event of glass tube damage.

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.