Oval Gear Flow Meter: Why It Still Dominates High-Viscosity Flow Measurement in Modern Automation

The Quiet Persistence of Oval Gear Flow Meters In an era where smart sensors, digital twins, and AI-driven instrumentation dominate...

Solving Stable Flow Measurement for Clean Liquids

The PTF 125 Pulse Output Intelligent Turbine Flowmeter is designed for accurate and repeatable flow measurement of clean liquids in industrial process control applications.

Based on the torque balance principle, the turbine sensor converts fluid kinetic energy directly into rotational motion, producing a high-frequency pulse signal proportional to flow rate.

With a simple mechanical structure, fast dynamic response, and multiple signal output options, PTF 125 is widely used in water, oil, and light hydrocarbon measurement where stability and signal reliability are critical.

Flow Meter Description

Turbine Type Flow Meter-Core Measurement Advantages

High measurement accuracy and repeatability

Torque-balanced turbine design ensures linear response within the calibrated flow range.

Sensitive response to flow changes

Ideal for process monitoring, batching, and totalizing applications.

Pulse output for control systems

Square-wave pulse signal suitable for PLC, DCS, counters, and data acquisition systems.

Multiple output options

Pulse, 4–20 mA, RS485, and HART protocols available.

Rugged industrial construction

Stainless steel body and wear-resistant impeller materials for long service life.

Flowmeter Turbine-Typical Applicable Media

PTF 125 is suitable for clean liquids compatible with stainless steel materials, including:

Water and demineralized water

Light oils and lubricants

Fuel oils and hydrocarbons

Other low-impurity industrial liquids

Note:

Free from fibers, particles, or solid impurities

Recommended viscosity ≤ 5 × 10⁻⁶ m²/s

Higher-viscosity liquids require calibration with the actual process fluid

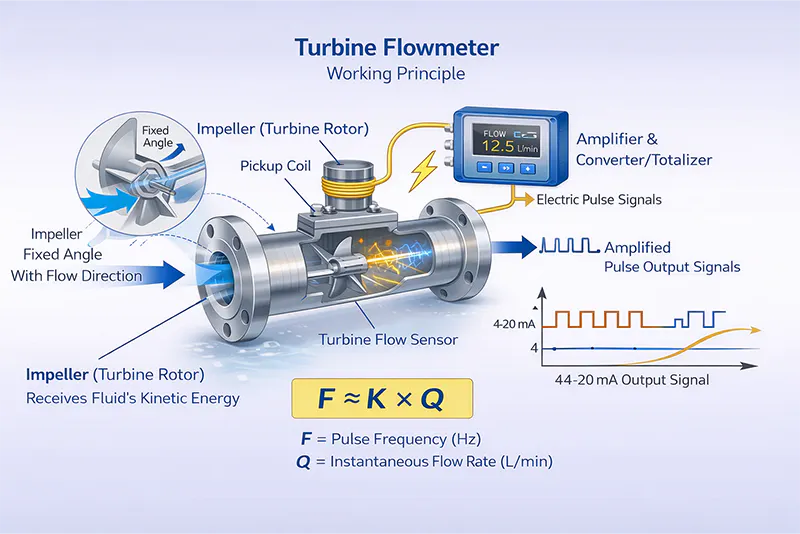

Turbine Flowmeter-Working Principle

When the measured liquid flows through the turbine flow sensor, the impeller blades—mounted at a fixed angle to the flow direction—receive kinetic energy from the fluid.

As the impeller rotates, it reaches a stable speed once fluid driving torque, friction torque, and resistance torque are balanced. Under defined conditions, the rotational speed of the impeller is directly proportional to the average flow velocity inside the pipe.

Each rotation of the impeller periodically changes the magnetic field at the detection coil, generating an electrical pulse signal. After amplification and signal processing, the system outputs:

Pulse signal

4–20 mA analog signal

Instantaneous flow rate

Totalized flow

Within the calibrated flow range, the relationship between pulse frequency and flow rate is:

Within the calibrated flow range, the pulse frequency is directly proportional to the instantaneous flow rate:

Q = 3600 × F / K

Where:

Pulse Output Intelligent Turbine Flowmeter Design

The intelligent pulse output module enables direct signal transmission to control and monitoring systems:

Power Supply Options: +12 VDC or +24 VDC

Signal Type: Square-wave pulse

Transmission Distance: ≤ 300 m

Output Amplitude:

~10 V at +12 V supply

~20 V at +24 V supply

Red wire: Power supply positive

White wire: Pulse output

Black wire: Ground

The amplifier is directly mounted to the turbine sensor via M16 × 1.0 threaded connection, ensuring compact installation and reliable signal integrity.

Flow Meter Parameter

| Item | Specification |

|---|---|

| Model | PTF 125 |

| Nominal Diameter | DN6 ~ DN200 |

| Medium | Clean liquids (water, oil, etc.) |

| Viscosity Range | 5 ~ 400 mPa·s |

| Operating Temperature | -20 ~ 120 ℃ |

| Nominal Pressure | PN16 ~ PN63 |

| Flow Range | ≤ 1200 m³/h |

| Accuracy Class | 0.5 / 1.0 / 1.5 |

| Body Material | SS304 / SS321 / SS316L |

| Impeller Material | 2Cr13 / Duplex Stainless Steel |

| Ambient Temperature | -20 ~ 60 ℃ |

| Ambient Humidity | 5 ~ 90% RH |

| Signal Output | Pulse / 4–20 mA / RS485 / HART |

| Power Supply | 24 VDC ±15% |

| Battery Option | 3.6 V Li-battery 10 Ah (no signal output) |

| Explosion Proof | Ex dⅡBT4 |

| Protection Grade | IP65 |

| Electrical Interface | M20 × 1.5 |

| Process Connection | Flange or Thread |

| Installation | Horizontal |

Instrava OEM/ODM

At Instrava, customization is not limited to parameter selection — it is about ensuring measurement reliability throughout the entire lifecycle of the application.

Instrava works closely with customers to tailor turbine flow meter configurations based on actual operating conditions, including:

Medium viscosity range and flow stability

Required pulse output level, frequency range, and signal interface

Nominal diameter, pressure rating, and material compatibility

Explosion-proof and environmental protection requirements

Each customized configuration is validated to ensure accurate pulse output and stable performance under real process conditions.

Beyond product delivery, Instrava provides:

Application consulting and meter selection guidance

Installation orientation and signal wiring recommendations

Support for calibration, commissioning, and signal integration

Long-term technical support for maintenance and performance optimization

Instrava positions itself not only as a supplier, but as a trusted long-term partner supporting customers and OEMs across China in safety-critical and process control applications.

Related Product Recommendations

Turbine flow meters perform best with low to medium viscosity liquids. As viscosity increases, fluid drag on the impeller rises, which can reduce rotational speed and impact accuracy. For higher-viscosity media, calibration using the actual process fluid is recommended to maintain reliable measurement.

The pulse output frequency is directly proportional to the instantaneous flow rate. Each pulse represents a fixed volumetric increment defined by the meter factor (K-value), making pulse output ideal for batching, totalizing, and PLC-based control systems.

Yes. Pulse output signals can typically be transmitted up to 300 meters, depending on wiring quality and electromagnetic environment. Proper grounding and shielded cables are recommended to ensure signal integrity in industrial installations.

Turbine flow meters must be installed in the correct flow direction and typically in horizontal pipelines. Incorrect orientation can affect impeller rotation stability, leading to inaccurate pulse output and reduced repeatability.

Turbine flow meters require clean liquids without fibers or solid particles. Particulates may damage the impeller or interfere with rotation, causing signal fluctuation or long-term wear.

Yes. Pulse output is widely used for instantaneous flow measurement, total flow accumulation, batching control, and system verification, making it highly compatible with PLC, DCS, and industrial automation systems.

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.

The Quiet Persistence of Oval Gear Flow Meters In an era where smart sensors, digital twins, and AI-driven instrumentation dominate...

Portable Ultrasonic Flow Meters – Accurate Industrial Flow Measurement | Instrava Portable Ultrasonic Flow Meters Overview Portable ultrasonic flow meters...

In industrial environments where pipeline shutdown, pipe cutting, or process interruption is not feasible, non-intrusive flow measurement has become an...