Why Optical Dissolved Oxygen Sensors Dominate Long-Term Monitoring

Long-term dissolved oxygen monitoring is fundamentally different from short-term measurement. While many dissolved oxygen sensors can deliver acceptable accuracy at...

Transmitter

Home » Products » Transmitters » Dissolved Oxygen Sensor

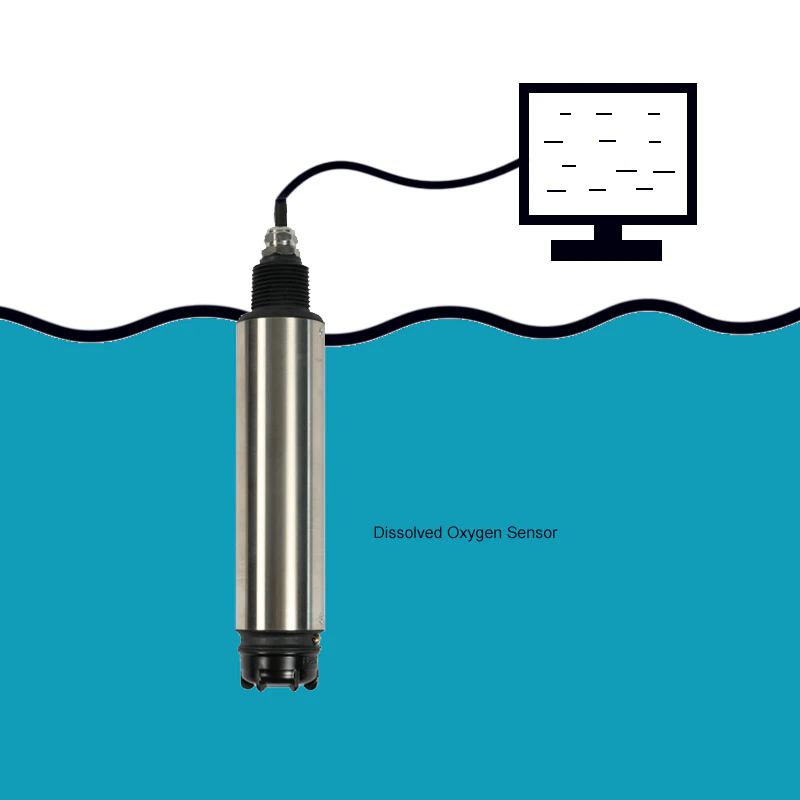

Designed for continuous dissolved oxygen monitoring in water and wastewater processes, this optical dissolved oxygen sensor eliminates the limitations of traditional membrane-based probes. With no electrolyte, no oxygen consumption, and no flow dependency, it delivers stable, accurate measurements even in low-flow or static conditions.

It is especially suitable for applications where long-term stability, low maintenance, and reliable digital communication are critical.

Transmitters & Sensors Description

Why Optical Dissolved Oxygen Measurement

Traditional electrochemical DO sensors require membranes, electrolytes, and frequent maintenance. This optical dissolved oxygen sensor adopts fluorescence measurement technology, providing a fundamentally different approach:

No membrane, no electrolyte, no polarization

No oxygen consumption during measurement

Stable readings independent of flow velocity

Longer service life with significantly reduced maintenance cost

This makes it ideal for unattended operation and harsh field environments.

Dissolved O2 Sensor Features

Membrane-free design with no electrolyte replacement

No polarization effect, no drift caused by oxygen consumption

Fluorescent cap is easy to replace when required

Fast response time and excellent long-term stability

Minimal annual drift ensures consistent performance

Built-in temperature sensor with automatic temperature compensation

Fully sealed IP68 housing for submersible installation

316L stainless steel + PPS body resists corrosion

Not affected by flow rate, bubbles, or low-velocity conditions

RS485 communication (Modbus-compatible)

Easy connection to PLC, SCADA, or upper-level control systems

Dissolved Oxygen Sensors Applications

Wastewater treatment (aeration basins, biological tanks)

Surface water and environmental monitoring

Aquaculture and fish farming systems

Industrial process water

Municipal water and utility monitoring

Dissolved Oxygen Sensor Designed for Long-Term Operation

By removing consumable components and minimizing maintenance requirements, this dissolved oxygen sensor significantly reduces total cost of ownership while ensuring reliable data for process control and environmental compliance.

It is not just a sensor—it is a long-term monitoring solution.

Transmitters & Sensors Parameter

| Parameter | Specification |

|---|---|

| Measurement Principle | Optical fluorescence |

| Dissolved Oxygen Range | 0 ~ 20 mg/L or 0 ~ 200 % saturation |

| Temperature Range (Process) | 0 ~ 45 ℃ |

| Operating Pressure | ≤ 0.3 MPa |

| Measurement Accuracy | DO: ±0.3 mg/L or ±3 %Temperature: ±0.5 ℃ |

| Output Signal | RS485 |

| Housing Material | 316L Stainless Steel + PPS |

| Protection Class | IP68 |

| Sensor Dimensions | Ø49.5 × 251.5 mm |

| Installation Method | Submersible |

| Ambient Temperature | 0 ~ 60 ℃ |

| Relative Humidity | < 90 % RH |

| Cable Length | 10 m standardUp to 100 m customizable |

Instrava OEM/ODM

Instrava goes beyond supplying sensors. We work as a long-term engineering partner, supporting customers from selection to deployment and long-term operation.

Application-oriented sensor selection

Sensor configuration optimized for wastewater, environmental water, aquaculture, or industrial processes.

Installation & mounting design

Support for submersible, pipeline, tank, or custom installation structures.

Signal & system integration

RS485 communication mapping for PLC, DCS, SCADA, and data acquisition systems.

Cable length & material customization

Extended cables (up to 100 m) and material options for harsh environments.

Multi-parameter system design

Integration with pH, ORP, conductivity, turbidity, and temperature sensors.

OEM & private labeling services

Branding, enclosure customization, and documentation support.

Pre-sales application analysis

Selection guidance for complex operating conditions

Commissioning support and parameter configuration

Long-term technical support and lifecycle consultation

Instrava focuses on trust, communication, and collaboration, helping customers reduce risk, improve reliability, and extend system service life.

Yes.

This sensor uses optical fluorescence technology and does not consume oxygen during measurement. The reading is independent of flow velocity, making it highly reliable in low-flow or stagnant conditions.

The optical measurement principle is far less sensitive to bubbles than electrochemical sensors. Occasional bubbles do not significantly affect readings, especially in aeration tanks or mixed water environments.

The sensor features minimal annual drift and no electrolyte consumption. Compared to membrane-based DO probes, it maintains accuracy over long periods with significantly reduced recalibration frequency.

Routine maintenance is minimal.

There is no membrane or electrolyte to replace. The fluorescent cap has a long service life and can be easily replaced when required, reducing downtime and maintenance cost.

Yes.

The sensor supports RS485 communication, typically using Modbus protocol, allowing seamless integration with PLC, DCS, SCADA, and data logging systems.

Absolutely.

With an IP68-rated housing and 316L stainless steel + PPS construction, the sensor is designed for continuous submersible operation in corrosive, high-humidity, and industrial wastewater conditions.

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.

Long-term dissolved oxygen monitoring is fundamentally different from short-term measurement. While many dissolved oxygen sensors can deliver acceptable accuracy at...

Dissolved oxygen (DO) measurement is a critical parameter in water treatment, aquaculture, environmental monitoring, and industrial processes. Among available technologies,...

How Measurement Data Becomes a Decision Variable in Modern Industrial Systems From Field Measurement to Process Decision In traditional process...