Level Measuring Instruments

Home » Products » Level Measuring Instruments » Bi Color Level Gauge for Boilers

Bi Color Level Gauge for Boilers

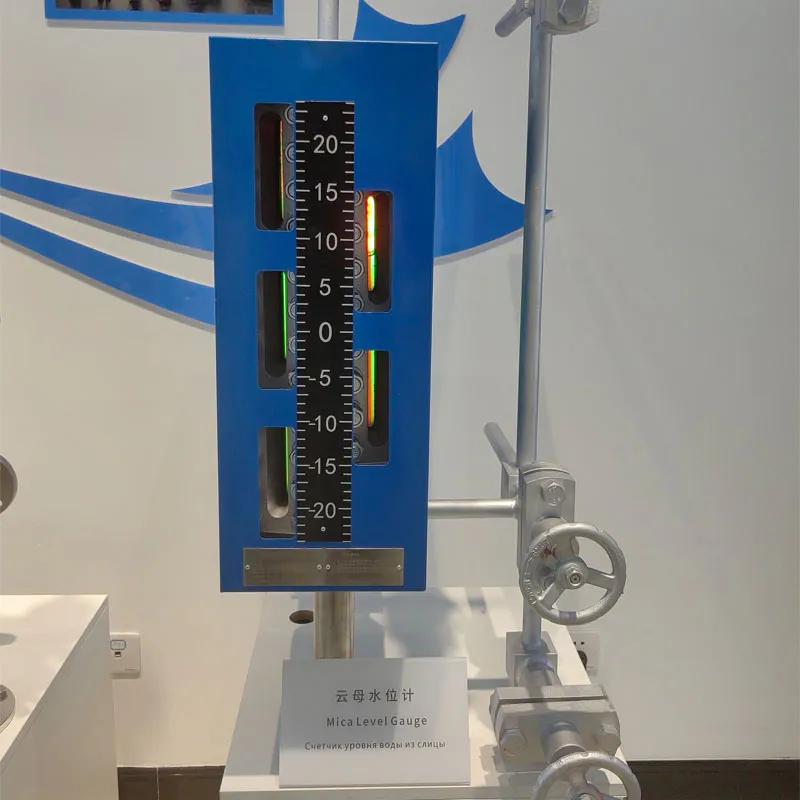

The observation windows of the bi color level gauge are arranged in two straight lines along the length of the gauge body. By adopting a staggered combination of observation holes, the central blind area is effectively eliminated, ensuring continuous and clear level visibility.

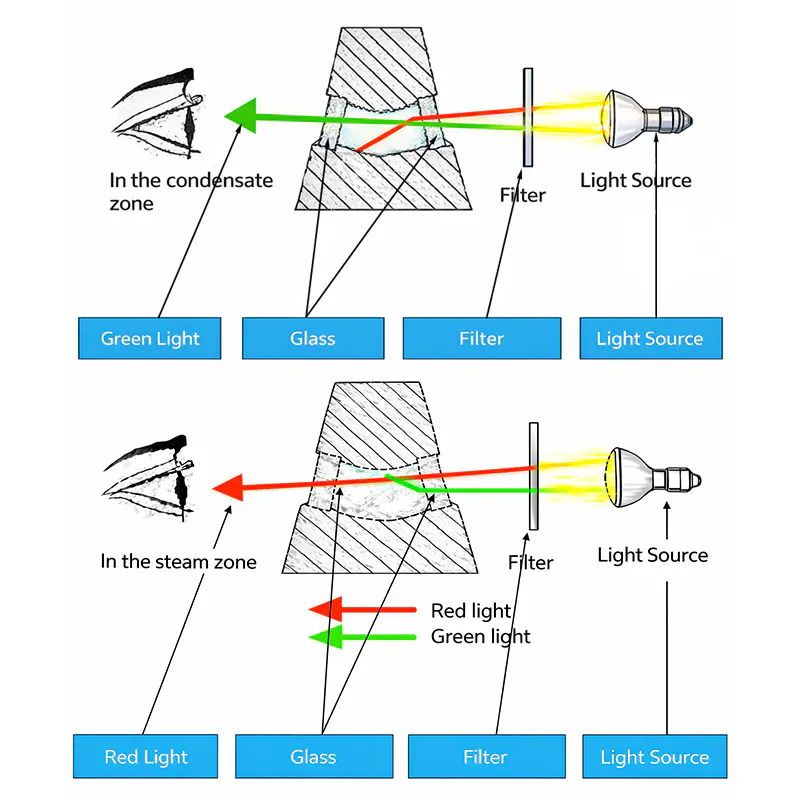

Red and green light emitted by the built-in light-emitting diodes are separately directed toward the observation window. In the vapor phase section of the gauge body, the red light travels directly toward the viewing direction, while the green light is refracted toward the chamber wall and absorbed.

In the liquid phase section, due to the refraction effect of the liquid, the green light is directed straight toward the observation window, while the red light is deflected toward the wall and absorbed. As a result, when viewed from the front, the vapor phase appears red and the liquid phase appears green, providing a clear and intuitive bi-color level indication.

Level Measuring Instruments Description

Bi-Colour Level Gauges-Features

Direct visual indication of the actual liquid level, allowing real-time observation without electrical power or signal conversion.

Equipped with an automatic quick shut-off mechanism that isolates vapor and liquid flow in case of leakage or glass damage, enhancing operational safety.

Well-engineered mechanical structure with standard connections, enabling simple installation, convenient maintenance, and reliable long-term operation.

Durable construction with minimal moving parts, resulting in low maintenance requirements and reduced operating costs.

Bicolor Level Gauge-Applications

The bi color level gauge is ideal for industrial systems where precise and reliable liquid level monitoring is required. Its dual-color display allows operators to quickly distinguish between liquid and vapor phases, making it suitable for a wide range of demanding environments:

Chemical & Petrochemical Plants: Monitors corrosive or hazardous liquids in reactors, storage tanks, and process vessels with high visibility and safety.

Boilers & Steam Systems: Provides accurate water level indication in boiler drums and steam vessels, resistant to high temperatures and pressure fluctuations.

Water Treatment & Industrial Tanks: Ensures clear and continuous observation of water or process liquid levels in filtration, storage, and circulation systems.

Food & Pharmaceutical Processing: Supports sanitary and clean operations where precise level indication is critical for production quality.

Oil & Gas Storage & Transportation: Enables safe, real-time monitoring of tanks, pipelines, and fuel storage under varying operational conditions.

This gauge is particularly effective in applications involving high temperature, high pressure, or steam conditions, offering stable performance and clear visual feedback even under challenging industrial conditions.

Bicolor Level Gauge-Working Principle

The bi color level gauge operates on the communicating vessel principle, where the liquid inside the gauge chamber maintains the same level as the connected vessel. Its dual-color optical design provides a clear distinction between liquid and vapor phases for instant visual identification.

Red and green LED lights are directed to the observation windows through a carefully designed optical path. In the vapor phase, red light travels straight to the observer while green light is absorbed by the gauge wall, making the vapor appear red. In the liquid phase, refraction causes green light to pass straight through and red light to be absorbed, producing a clear green display.

This visual contrast allows operators to monitor liquid levels accurately in real time, even under high temperature, high pressure, or steam conditions. The gauge also integrates a safety steel ball shut-off mechanism, which isolates vapor and liquid flow in the event of glass damage, ensuring safe operation and maintenance.

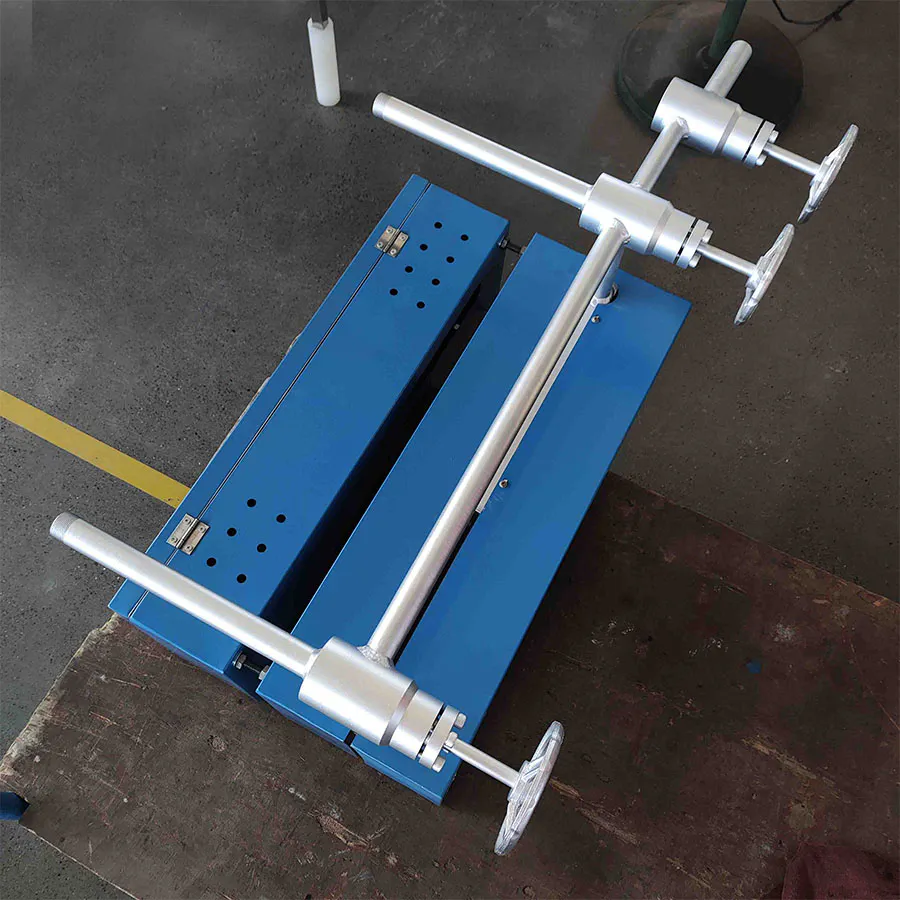

Bi Color Level Gauge-Structure

The bi color level gauge mainly consists of a gauge body, bi-color glass plates, upper and lower valves, drain valve, and an internal safety protection mechanism. The gauge is connected to the vessel via standard flanges or threaded connections.

The optical glass structure enhances color contrast, while the metal housing provides mechanical strength and protection, ensuring stable operation in demanding industrial environments.

- Red light diode

- Aluminum profile light stand

- Green light diode

- Wing nut

- Light source cover

- Insulation board

- Insulation glass

- Body

- Observation cover

- Scale

Level Measuring Instruments Parameter

| Bi Color Level Gauge-Type | INBI113 |

| Medium | liquid or material that is generally or slightly corroded |

| Measuring Range | 5m, 10m, 15m, 30m, 50m, 60m,120m |

| Transducer Material | Ceramic |

| Measurement Error | 0.5%. 1.0% |

| Accuracy | ±3mm (no wave calm water surface) |

| Resolution | 3~5mm or 0.1% (take large value) |

| Display Mode | LCD, parameters can be set through the panel buttons |

| Signal Output | 4~20mADC |

| Relay Output | 2 groups are optional, and the relay status is programmable |

| Working Temperature | -25~80℃ |

| Communication Interface | RS232, RS485/Modbus |

| Electrical Interface | M20*1.5, 1/2″NPT |

| Explosion-proof Grade | ExiaIICT6Ga/ExdIICT6Gb |

| Protection level: | IP67 |

| Shell material: | engineering-plastics, aluminum alloy, SS304 |

| Ambient temperature: | (meter) -20-60℃; (sensor) -20~80℃ |

| Relative Humidity | 95% |

Level Measuring Instruments OEM/ODM

OEM / ODM Customization

Instrava offers flexible OEM and ODM solutions for bi color level gauges, providing tailored designs to meet specific industrial requirements. Customers can customize:

Materials & Construction: Borosilicate or quartz glass, stainless steel or carbon steel frames, corrosion-resistant coatings.

Pressure & Temperature Ratings: Designed for high-temperature, high-pressure, and steam environments.

Connection Types: Flanged, threaded, or special connections to match your vessels.

Dimensions & Orientation: Gauge length, chamber size, and installation configuration customized for your process.

As a trusted partner in China, Instrava combines engineering expertise with rigorous quality control, ensuring every customized gauge delivers reliable, long-lasting performance. We work closely with customers and OEM partners, providing solutions and services for safety-critical and process control applications, helping improve operational efficiency and minimize downtime.

With Instrava’s OEM/ODM service, you get not just a product, but a fully supported industrial solution designed for precise liquid level monitoring in chemical, boiler, water treatment, and general industrial applications.

Related Product Recommendations

A bi color level gauge, also called a sight glass level indicator, is a visual instrument for monitoring liquid levels in tanks and vessels. It uses dual-color optical technology to distinguish liquid (green) and vapor (red) phases, providing instant, real-time level observation without electrical power. This makes it ideal for chemical, boiler, and industrial process applications.

Bi color level gauges are available in transparent, reflex, and mirror-type configurations. Transparent gauges are best for clear liquids, reflex types improve visibility in steam or high-temperature systems, and mirror-type gauges enhance readability in low-light or medium-pressure vessels.

Bi color level gauges are widely used in chemical, petrochemical, boiler, water treatment, food, pharmaceutical, and oil & gas industries. They are especially suitable for high-temperature, high-pressure, or steam conditions where reliable liquid level monitoring is critical for process safety and efficiency.

The gauge should be installed via standard flanges or threaded connections to the vessel. Before operation, pressure testing is required. During use, valves should be opened gradually, and the gauge should be checked regularly for leaks. Contaminated glass can be safely cleaned after draining the medium and relieving pressure, ensuring long-term reliable performance.

Most bi color level gauges feature a built-in safety steel ball. If the glass plate breaks or vapor/liquid pressure exceeds the rated threshold, the steel ball automatically seals the flow path. This prevents media leakage, protects personnel, and ensures safe operation in chemical, boiler, and industrial vessels.

Bi color level gauges are designed for high-temperature and high-pressure industrial applications. The dual-color optical system ensures clear visual differentiation between liquid and vapor phases, even under steam or superheated conditions. High-strength borosilicate or quartz glass and corrosion-resistant metal housings provide mechanical stability, while the built-in safety steel ball prevents media leakage if the glass is damaged, ensuring reliable and safe operation in demanding chemical, boiler, or industrial processes.

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.