Wedge Flow Meter

The wedge flow meter is a differential pressure flow measurement instrument designed for accurate and stable flow measurement under harsh industrial conditions. It integrates a wedge-type flow sensor with a differential pressure transmitter to provide reliable performance for complex process applications.

It is especially suitable for measuring city gas and natural gas with large flow fluctuations, where flow rates may vary significantly over time. It also effectively solves flow measurement challenges for high-viscosity media such as pitch, asphalt, residual oil, and paraffinic oil.

With its simple structure, strong resistance to clogging, and stable differential pressure signal, the wedge flow meter performs reliably in corrosive, dirty, and slurry applications, including saturated or crystallizing acidic, alkaline, and saline liquids.

The wedge flow meter is ideal for extreme conditions, supporting Reynolds numbers as low as 500 and fluid viscosities up to 500 mPa·s, offering a low-maintenance and cost-effective solution for industrial flow measurement.

Flow Meter Description

Optimized Product Features 1 – Wedge Flow Meter

High accuracy and excellent stability

Measuring accuracy up to ±0.5% F.S, with long-term stability of ±0.1% F.S/year, ensuring reliable and repeatable flow measurement.Simple and robust structure with long service life

The wedge-shaped flow sensor features a proven differential pressure design. After strict testing and calibration, the service life can reach up to 10 years, enabling up to 5 years of maintenance-free operation.Wide measuring range

Standard turndown ratio of 1:25, expandable to 1:33, and up to 1:100 with differential pressure adjustment, suitable for applications with large flow variations.Wide application range for complex media

Suitable for single-phase fluids as well as two-phase media (gas–liquid, gas–solid, liquid–solid). Operates with Reynolds numbers as low as 300 and up to 1×10⁷.Anti-adhesion and non-clogging design

The special wedge structure and smooth measuring pipe prevent adhesion, deposition, and clogging by silt, powder, suspended solids, and fibers, ensuring long-term measurement accuracy.

Optimized Product Features 2 – Wedge Flowmeter

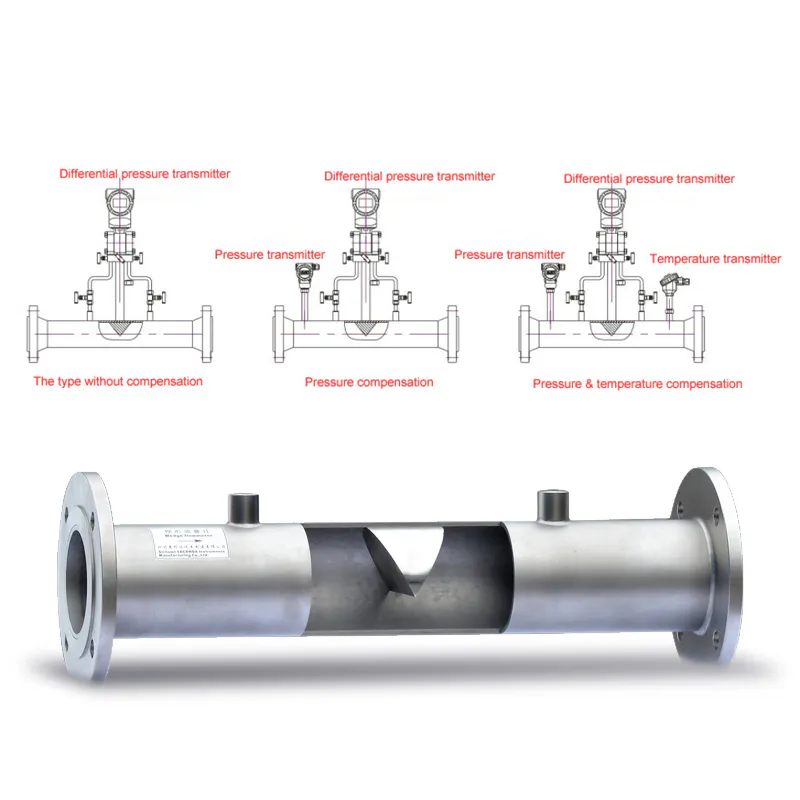

Integrated installation design

Integrates the wedge sensor, three-valve manifold, and differential pressure transmitter into a single unit, eliminating impulse lines and fittings, simplifying installation, and improving measurement accuracy.Intelligent and configurable

Supports HART and other communication protocols for parameter configuration. Enables automatic adjustment of differential pressure based on medium changes and supports multi-parameter measurement, including differential pressure, volumetric flow, mass flow, pressure, and temperature, with full temperature compensation.Low straight pipe length requirement

Requires minimal upstream and downstream straight pipe lengths, effectively reducing installation uncertainty and improving measurement reliability.Low permanent pressure loss

Optimized flow structure minimizes pressure loss, helping reduce energy consumption and operating costs.

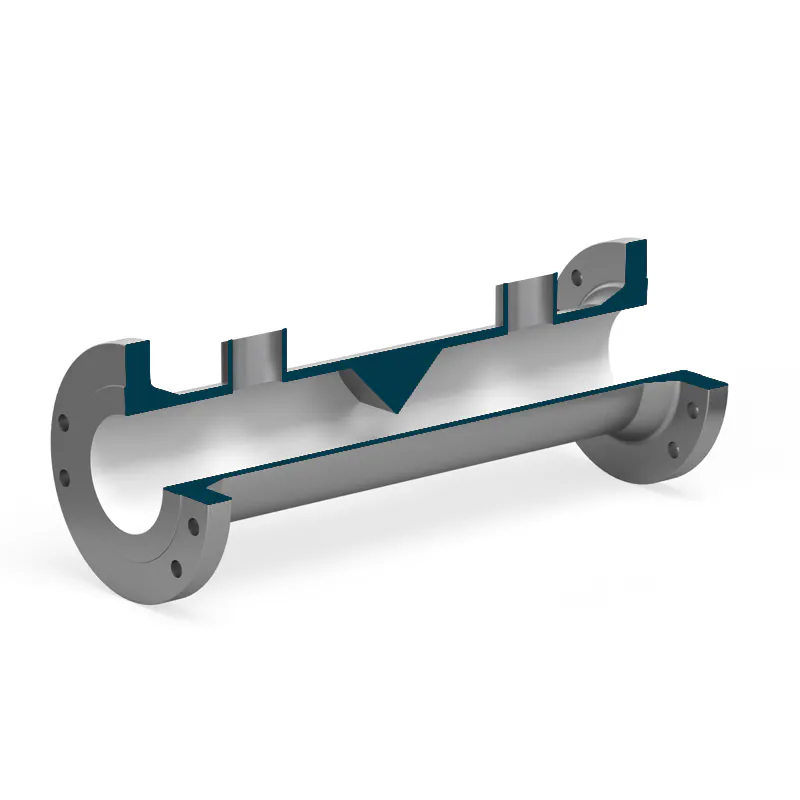

Working Principle of Wedge Flow Meter

The wedge flow meter operates on the same differential pressure measurement principle as traditional orifice plates and Venturi flow meters, based on the Bernoulli equation and the law of conservation of mass.When fluid flows through a throttling element, a differential pressure is generated,which is proportional to the square of the flow rate.

The sensing element of the wedge flow meter is a V-shaped wedge throttling element.Its rounded downstream edge and special geometry effectively reduce upstream vortex formation,prevent particle accumulation, and avoid blockage when measuring high-viscosity, dirty, slurry, or particle-laden media.

As the fluid passes through the wedge, a stable differential pressure is produced.The square root of the differential pressure is directly proportional to volumetric flow rate or mass flow rate.The measuring range is determined by the ratio of the wedge height H to the pipe inner diameter D (H/D ratio).

Flow Calculation Formula

Volume flow rate:

qv =

C · ε · m · (πD2 / 4) · √(2ΔP / ρ) / √(1 − m2)

Parameter Definitions

- qv – Volume flow rate (m³/s)

- C – Flow coefficient

- ΔP – Differential pressure (Pa)

- ε – Expansion factor

- D – Inner diameter of pipe (m)

- ρ – Fluid density (kg/m³)

- m – Throttle area ratio

Throttle Area Calculation

m = S1 / (πD2 / 4)

Arch flow area (S1):

S1 = 1/2 · r · l − x · (r − h)

x = 2√[h(2r − h)]

l = 0.01745 · r · α

Thanks to its stable differential pressure signal and anti-clogging structure,the wedge flow meter maintains long-term measurement stability of up to

±0.1% F.S/year, making it an ideal solution for the most challenging industrial flow measurement applications.

Wedge Type Flow Meter Product Applications

Wedge flow meters are widely used in:

City gas and natural gas distribution systems

Oil, asphalt, pitch, and residual oil pipelines

Chemical and petrochemical processing plants

Slurry, sludge, and wastewater treatment systems

Steam and condensate measurement

Corrosive acid, alkali, and saline fluid measurement

Flow Meter Parameter

Model: WF 122

| Parameter | Specification |

|---|---|

| Accuracy Class | 0.5 (0.2 / 0.3 / 0.4 available on request) |

| Long-term Stability | ±0.2% F.S / year |

| Repeatability | ±0.2% |

| Applicable Media | Liquids, gases, and steam |

| Minimum Flow Velocity | 0.01 m/s |

| Measuring Range (Turndown Ratio) | Standard: 1:25; Maximum: 1:33 |

| Permanent Pressure Loss | Approx. 1/5 of measuring differential pressure (about 1/3 of an orifice plate) |

| Reynolds Number Range | ≥500 to ≤1 × 10⁷ |

| Medium Viscosity | ≥500 mPa·s |

| Working Pressure Range | –0.1 to 42 MPa |

| Working Temperature Range | –160 °C to 450 °C (up to 700 °C max) |

| Pipe Size | DN10 to DN1200 (up to DN2500 on request) |

| Wedge Ratio (h/D) | 0.2 / 0.3 / 0.4 / 0.5 |

| DP Transmitter Power Supply | 24 V DC |

| DP Transmitter Output | 4–20 mA DC (HART) |

Flow Meter OEM/ODM

Customization & OEM Service

Wedge flow meters can be customized to suit specific operating conditions, including:

Pipe diameter and pressure rating

Material selection for corrosive or abrasive media

Pressure tapping configuration

Integrated or remote differential pressure transmitter

Special designs for high-temperature or high-pressure applications

Instrava is a partner focused on providing equipment, solutions, and services for industrial measurement and control instruments used in safety-critical and process control applications. We are committed to providing reliable and long-lasting solutions based on trust, communication, and collaboration, helping customers improve process efficiency and measurement reliability.

As a trusted long-term partner for customers and OEM partners in China, Instrava provides professional OEM and customization services for wedge flow meters and industrial flow measurement solutions.

Related Product Recommendations

Wedge flow meters are specifically designed for applications with wide flow variations. With a standard turndown ratio of 1:25 (expandable to 1:33 or higher), they maintain stable differential pressure signals even when flow rates change significantly, making them ideal for city gas, natural gas, and batch processes.

Yes. The wedge flow meter performs reliably with fluid viscosities exceeding 500 mPa·s and supports Reynolds numbers as low as 500. Its wedge-shaped throttling element minimizes flow separation and signal distortion, allowing accurate measurement of high-viscosity, shear-sensitive, and non-Newtonian fluids.

Absolutely. The non-clogging wedge structure prevents the accumulation of solids, fibers, and sediments. This makes wedge flow meters especially suitable for slurry, wastewater, pulp, sludge, and crystallizing chemical media where traditional orifice plates may fail.

A wedge flow meter typically generates only about one-third of the permanent pressure loss of an orifice plate under similar operating conditions. This significantly reduces energy consumption while maintaining accurate differential pressure measurement.

Wedge flow meters require shorter upstream and downstream straight pipe lengths compared to traditional differential pressure flow meters. This makes them well suited for retrofit projects and installations with limited piping space.

Thanks to its robust structure and absence of moving parts, the wedge flow meter requires minimal maintenance. In most applications, it can operate up to 5 years without recalibration, providing long-term stability of ±0.2% F.S/year and reducing total cost of ownership.

Why Choose Instrava

By choosing Instrava, you gain a partner with a deep understanding of industrial applications and the expertise to meet today’s operational challenges.

Our role extends beyond products—we support your success through dependable solutions and long-term commitment.

Engineering-Driven Innovation

Innovation at Instrava is guided by real industrial requirements. We continuously refine our technologies to address evolving operational challenges, ensuring practical and reliable performance in demanding environments.

Application-Specific Customization

We provide engineering-level customization to match specific process conditions. From measurement range and materials to output signals and installation options, our solutions are configured to fit real applications.

Proven Quality and Reliability

Quality and reliability are fundamental to every Instrava product. Manufactured under strict quality control and thoroughly tested, our instruments deliver accurate, stable, and long-term performance.

Global Capability with Local Support

Instrava combines global engineering expertise with responsive local support, ensuring our partners benefit from internationally aligned technology and timely regional service.

Comprehensive Product Portfolio

Our broad portfolio of measurement and control instruments enables us to address a wide range of industrial needs, providing integrated solutions from a single, reliable source.

Partner-Oriented Engineering Support

We work closely with our partners from technical consultation to after-sales support. Our focus is on delivering solutions that create lasting value and support long-term operational success.