Propane Tank Level Gauge Solution | Industrial Level Indicator

A

level gauge designed for propane storage plays a critical role in ensuring safe operation, accurate inventory control, and long-term system reliability. In pressurized propane tanks, level indication is not a secondary accessory but a core safety and operational component. A properly engineered

propane tank gauge level indicator allows operators and engineers to clearly understand liquid level conditions during filling, storage, and withdrawal.This solution page focuses on

level gauge solutions specifically engineered for propane tanks, addressing real-world operating conditions in oil and gas facilities, LNG/LPG storage terminals, and OEM-integrated propane systems. Rather than presenting generic level measurement concepts, this page explains how to select and apply the right level gauge technology for propane service.

Propane Tank Level Measurement Challenges

Propane is stored as a liquid under pressure, which introduces several technical challenges for level indication:

- Pressurized vessels: Level gauges must withstand sustained internal pressure

- Temperature influence: Ambient temperature affects propane vapor pressure

- Hazardous environments: Many installations require explosion-proof certification

- Outdoor exposure: UV radiation, moisture, and corrosion impact long-term performance

A standard level indicator may not perform reliably under these conditions. A dedicated

propane tank gauge level indicator must be selected based on mechanical strength, sealing integrity, and certified safety compliance.

Recommended Level Gauge Technologies for Propane Tanks

Different level gauge technologies can be applied to propane tanks, but not all provide the same level of reliability or suitability. Below are the most widely accepted solutions in industrial propane storage.

Magnetic Level Gauge for Propane Tanks

A magnetic level gauge is one of the most proven solutions used as a

propane tank gauge level indicator. The system uses a float containing a permanent magnet that travels with the liquid propane inside an external chamber connected to the tank.

Why magnetic level gauges are widely used:- Clear local visual indication

- No external power required

- Excellent pressure and temperature resistance

- Suitable for hazardous and classified areas

Magnetic level gauges are commonly selected for LPG and propane tanks in oil and gas facilities due to their mechanical reliability and low maintenance requirements.

Radar Level Gauge for Large Propane Tanks

Radar level gauges measure liquid level using microwave signals reflected from the propane surface.

Key advantages:- Non-contact measurement

- High measurement accuracy

- Minimal maintenance

Engineering considerations:- Antenna selection must match tank geometry

- Installation space and nozzle size must be evaluated

Radar level gauges are typically applied to large propane tanks and terminals where continuous monitoring and remote signal transmission are required.

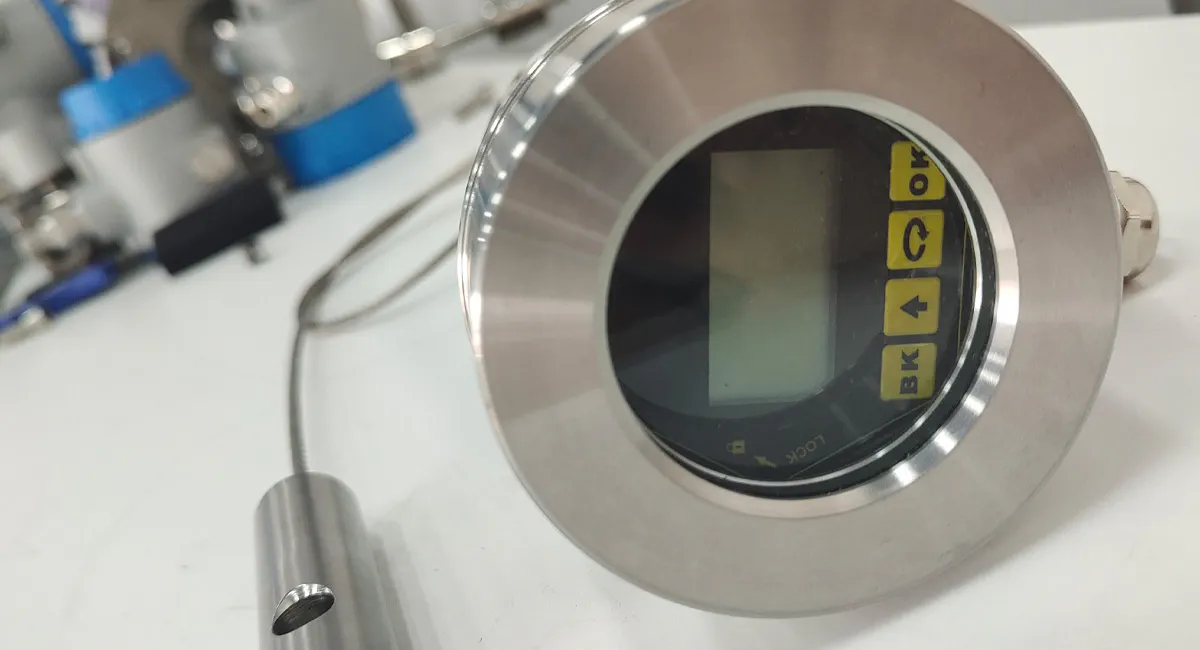

Guided Wave Radar Level Gauge

Guided wave radar level gauges transmit microwave pulses along a probe immersed in the liquid propane.

Benefits for propane applications:- Stable measurement under pressure

- Reliable performance in narrow or tall tanks

- Suitable for continuous level monitoring

This technology is often selected for OEM-built propane skids and packaged storage systems.

Mechanical Float-Type Level Gauge

Mechanical float-type gauges are still used in certain propane applications, particularly on smaller tanks.

Limitations:- Limited accuracy

- Visual-only indication

- Restricted suitability for industrial automation

For industrial-scale propane storage, more robust level gauge solutions are generally preferred.

Level Gauge Technology Comparison for Propane Tanks

Suggested comparison table data:- Magnetic level gauge: Contact type, visual indication, high pressure rating, widely used in industrial propane tanks

- Radar level gauge: Non-contact, high accuracy, suitable for large tanks, higher initial cost

- Guided wave radar: Contact type, high accuracy, suitable for pressurized vessels, medium to high cost

- Mechanical float gauge: Contact type, basic indication, limited accuracy, small tanks

Key Engineering Parameters for Propane Tank Gauge Level Indicator Selection

When specifying a

level gauge for propane tanks, engineers should evaluate the following parameters:

- Design pressure: Level gauge rating must exceed maximum tank pressure

- Temperature range: Suitable for propane phase behavior

- Measurement purpose: Safety indication, inventory monitoring, or both

- Local visibility: Readability from a safe operating distance

- Signal output options: Optional transmitters for remote monitoring

- Certification requirements: ATEX, IECEx, or equivalent standards

Selecting a propane tank gauge level indicator without considering these factors may lead to unreliable performance or safety risks.

Typical Applications

Oil and Gas Facilities

In oil and gas installations, propane tanks support auxiliary fuel systems, process heating, and temporary storage. Level gauges in these environments must operate reliably under continuous service and variable ambient conditions.

LNG and LPG Storage Terminals

LNG and LPG terminals rely on accurate level gauges to ensure safe filling operations and maintain inventory visibility. Magnetic and radar-based level gauges are widely adopted due to their durability and compatibility with safety management systems.

OEM-Integrated Propane Systems

OEM manufacturers of propane skids and modular storage units often specify level gauges that offer standardized installation, long service life, and optional signal transmission for system integration.

Installation and Maintenance Considerations

To ensure long-term performance of a propane tank gauge level indicator, the following practices are recommended:

- Verify process connection size and orientation

- Use isolation valves where required for maintenance

- Follow sealing and torque specifications

- Conduct functional checks before commissioning

Periodic inspection helps confirm visual clarity, mechanical integrity, and continued operational reliability.

Common Specification Risks

Common risks when selecting a level gauge for propane tanks include:

- Underspecifying pressure or temperature ratings

- Selecting devices without hazardous area certification

- Ignoring future monitoring or expansion needs

- Relying solely on basic mechanical indicators for critical applications

Addressing these risks early in the design stage improves safety and system reliability.

Solution Summary

A properly engineered

level gauge is essential for safe and efficient propane storage. By selecting the right

propane tank gauge level indicator technology—whether magnetic, radar, or guided wave radar—engineers can achieve reliable level indication under demanding operating conditions.This propane tank level gauge solution is designed to support oil and gas facilities, LNG/LPG storage terminals, and OEM-integrated systems that require dependable level visibility, regulatory compliance, and long-term operational confidence.

Technical Consultation

For propane tank projects with specific pressure ratings, tank geometries, or certification requirements, a structured technical review helps ensure the selected level gauge solution aligns with system design and operational objectives.