Water Level Sensor: Industrial Technologies, Applications, and Engineering Selection Guide

Introduction

A water level sensor is a fundamental instrument used to measure and monitor liquid levels in industrial systems. In sectors such as oil and gas, chemical processing, water and wastewater treatment, and LNG/LPG storage, accurate level measurement is essential for safe operation, process efficiency, and regulatory compliance.

Unlike basic consumer-level devices, an industrial water level sensor is designed to operate under demanding conditions, including high pressure, extreme temperatures, corrosive media, and hazardous environments. As industrial automation and digital monitoring continue to advance, water level sensors play an increasingly critical role in modern process control systems.

This article provides a professional, engineering-focused overview of water level sensor technologies, industrial applications, and key selection considerations, helping technical teams and project stakeholders make informed decisions.

What Is a Water Level Sensor?

A water level sensor is a device that detects, measures, and transmits the level of water or other liquids inside tanks, vessels, pipelines, reservoirs, or open channels. Depending on the measurement principle, a water level sensor can provide:

- Continuous level measurement

- Point-level detection (high or low alarms)

- Analog or digital output signals

- Integration with PLC, DCS, or SCADA systems

In industrial environments, a water level sensor must deliver stable and repeatable measurements over long operating periods with minimal maintenance.

Main Types of Water Level Sensor Technologies

Different process conditions require different sensing principles. Below are the most commonly used water level sensor technologies in industrial applications.

Radar Water Level Sensor

Radar-based water level sensors use microwave signals to measure the distance between the sensor antenna and the liquid surface.

Key characteristics:

- Non-contact measurement

- High accuracy (typically ±1–3 mm)

- Unaffected by temperature, pressure, or vapor

- Suitable for hazardous and explosive areas

Typical applications:

- Oil and gas storage tanks

- LNG and LPG vessels

- Chemical reactors

- Large industrial water reservoirs

Guided Wave Radar Water Level Sensor

A guided wave radar water level sensor transmits microwave pulses along a probe immersed in the liquid. The reflected signal indicates the liquid level.

Advantages:

- Stable performance in narrow or tall tanks

- Reliable measurement with foam or turbulence

- Suitable for interface level measurement

Common applications:

- Chemical processing units

- Separators and buffer tanks

- Skid-mounted systems

Ultrasonic Water Level Sensor

Ultrasonic water level sensors measure the time required for sound waves to travel to the liquid surface and return.

Advantages:

- Non-contact operation

- Cost-effective solution

- Simple installation and setup

Limitations:

- Influenced by vapor, dust, and temperature changes

- Less suitable for high-pressure or enclosed vessels

Typical applications:

- Water and wastewater treatment plants

- Open channels, sumps, and basins

Hydrostatic (Pressure) Water Level Sensor

Hydrostatic water level sensors determine liquid level by measuring the pressure at the bottom of a tank or column.

Advantages:

- Simple and proven measurement principle

- Suitable for deep tanks

- Good accuracy in stable-density liquids

Considerations:

- Measurement affected by density changes

- Direct contact with the process medium

Capacitive Water Level Sensor

Capacitive water level sensors detect changes in capacitance caused by variations in liquid level.

Advantages:

- Compact design

- Suitable for small tanks and vessels

- Works with conductive and non-conductive liquids

Typical applications:

- OEM equipment

- Dosing and batching systems

Comparison Data for Water Level Sensor Technologies

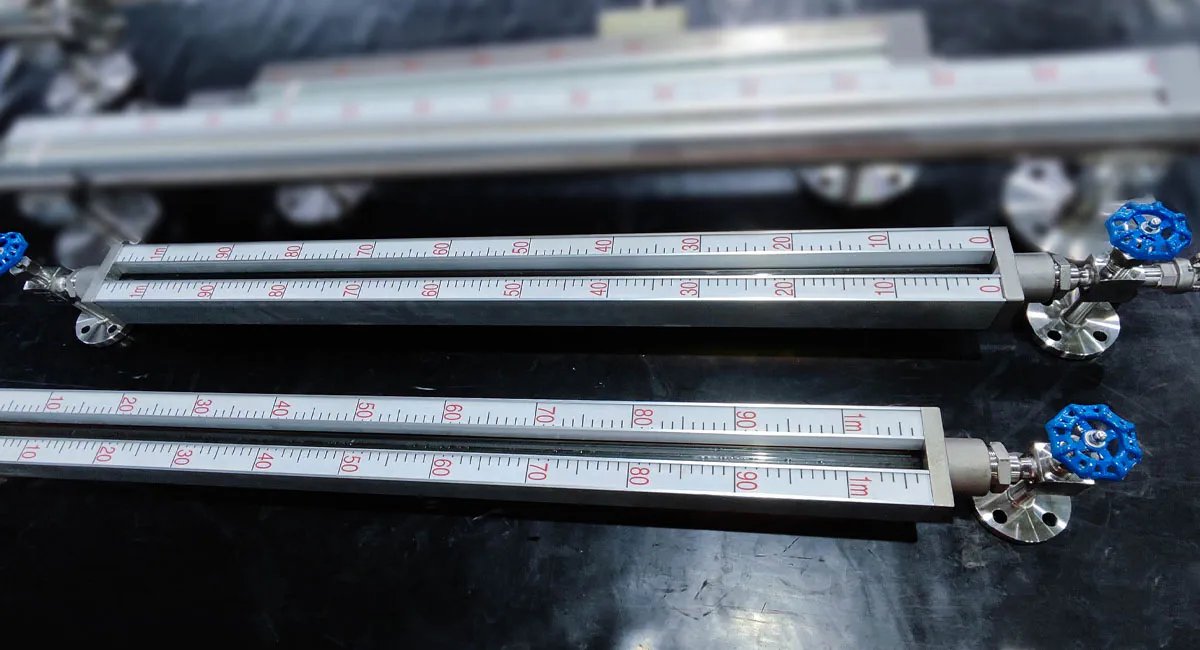

| Feature | Magnetic Level Gauge | Radar Level Gauge |

|---|---|---|

| Measurement Type | Contact | Non-contact |

| Visual Indication | Yes | Optional with external display |

| Accuracy | High for local monitoring | High for all conditions |

| Temperature Tolerance | Good | Excellent |

| Pressure Tolerance | Good | Excellent |

| Corrosive Media | Requires material selection | Excellent non-contact solution |

| Maintenance | Low | Very low |

| Power Requirement | Not required | Required for signal output |

| Remote Monitoring | Optional | Standard output (4–20 mA, HART) |

Industrial Applications of Water Level Sensors

Oil and Gas Industry

In oil and gas operations, a water level sensor is used in crude oil tanks, produced water systems, separators, and offshore platforms. Radar and guided wave radar water level sensors are commonly selected due to their reliability, safety certifications, and resistance to harsh operating conditions.

Chemical Processing Plants

Chemical facilities require water level sensors that can withstand corrosive fluids, elevated temperatures, and high pressures. Non-contact radar water level sensors and coated guided wave radar probes are widely used in reactors, storage tanks, and process vessels.

Water and Wastewater Treatment

In water and wastewater treatment plants, water level sensors are critical for pump control, overflow prevention, and process optimization. Ultrasonic and hydrostatic water level sensors are commonly applied due to their cost-effectiveness and ease of maintenance.

LNG and LPG Storage

Cryogenic storage applications demand water level sensors with high measurement stability and resistance to extreme temperatures. Radar water level sensors with specialized antennas are widely adopted in LNG and LPG tanks.

Key Selection Criteria for Water Level Sensors

When selecting a water level sensor, technical teams should evaluate the following factors:

- Process conditions: temperature range, pressure rating, and presence of foam or vapor

- Medium properties: density, conductivity, and corrosiveness

- Installation constraints: tank geometry, nozzle size, and available mounting locations

- Output and communication: 4–20 mA, HART, Modbus, or fieldbus protocols

- Compliance requirements: ATEX, IECEx, SIL, CE

Data for Industry Adoption Chart

Integration with Automation Systems

Modern water level sensors are designed for seamless integration with industrial automation platforms. Diagnostic functions, remote configuration, and predictive maintenance capabilities help reduce downtime and improve overall system reliability.

Common Selection Challenges

Common challenges when specifying a water level sensor include:

- Selecting technology without considering process conditions

- Ignoring long-term maintenance requirements

- Overlooking certification and compliance needs

- Using general-purpose sensors in demanding industrial environments

A structured evaluation process helps ensure long-term performance and reliability.

Conclusion

A water level sensor is a critical component in industrial measurement and control systems. By understanding available technologies, application requirements, and selection criteria, engineers and project teams can ensure accurate level measurement, improved safety, and reliable long-term operation across a wide range of industrial processes.